Leon Mk1

|

| 1 - | 23 Nm |

| q | Fit with thread locking agent → ETKA (electronic parts catalogue) |

| 2 - | Camshaft wheels |

| q | The notched belt must be removed prior to removing or installing → Chapter |

| q | Installation position, fixed with a cotter pin → Item |

| 3 - | 100 Nm |

| q | Use the counterhold -T20018B- to loosen and tighten → Fig. |

| 4 - | 10 Nm |

| q | Fit with thread locking agent → ETKA (electronic parts catalogue) |

| 5 - | Rear notched belt guard |

| 6 - | Woodruff key |

| q | Check that it is seated securely |

| 7 - | Seal |

| q | Renew |

| 8 - | 10 Nm |

| 9 - | Breather pipe |

| q | To expansion tank |

| 10 - | Special bolt - 9 Nm |

| q | Renew if damaged or leaking. |

| q | Note correct sequence when tightening → Anchor |

| 11 - | Seal |

| q | Renew if damaged or leaking. |

| 12 - | Sealing plug |

| 13 - | Cylinder head cover: |

| q | Removing and fitting → Chapter |

| q | For removal, unscrew the bolts from the interior towards the exterior |

| q | For fitting, tighten the bolts from the interior towards the exterior |

| 14 - | Cylinder head cover gasket |

| q | Renew if damaged or leaking. |

| q | Fit in the spacer sleeves → Item |

| 15 - | Cylinder head bolt |

| q | Renew |

| q | Use thewrench -T20079- |

| q | Note the fitting order when loosening → Anchor and tightening → Anchor bolts |

| 16 - | 10 Nm |

| 17 - | Hall sender -G40- |

| q | Gold plated contacts |

| 18 - | O ring |

| q | Renew |

| 19 - | Cylinder head |

| q | Cylinder head: Removing and installing → Chapter |

| q | The sealing surface on the camshaft side may not be reworked |

| q | See note → Chapter. |

| q | Valve guides: check → Chapter |

| q | Valve seats: reworking → Chapter |

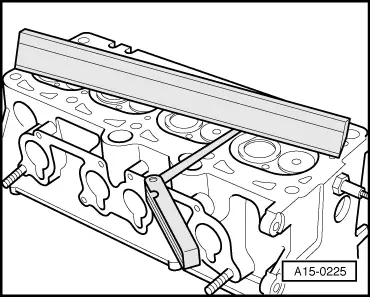

| q | Check for deformation → Fig. |

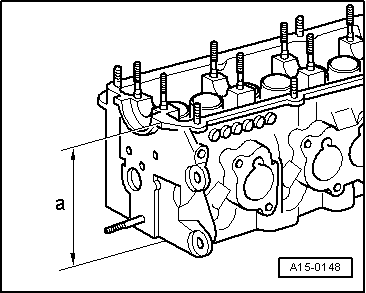

| q | Cylinder head: Reworking dimensions → Fig. |

| q | Renew coolant after replacing |

| q | Engines with engine codes CCSA, CMXA: toughened inlet and exhaust valves, valve seats made of wear-resistant material. |

| 20 - | Joint mouth |

| 21 - | 10 Nm |

| 22 - | O ring |

| q | Renew |

| 23 - | Cylinder head gasket |

| q | Renew → Chapter |

| q | Observe correct installation position of the cylinder head gasket: The Part No. should be legible from inlet side. |

| q | Renew coolant after replacing |

|

|

|

|