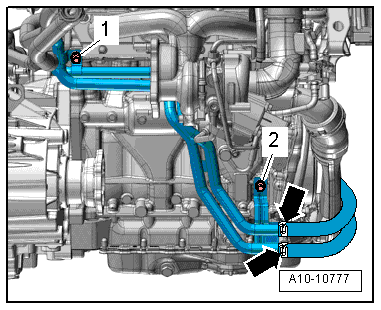

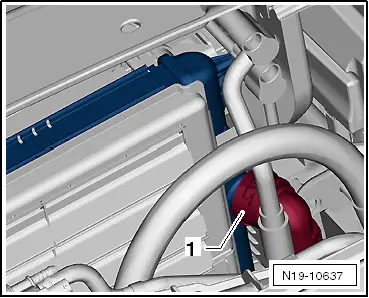

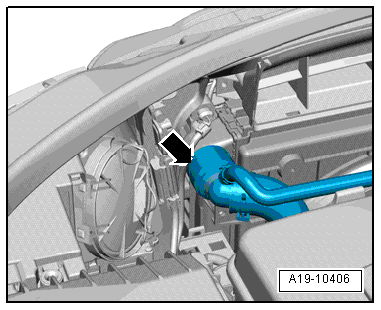

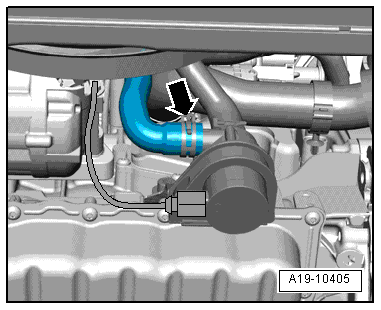

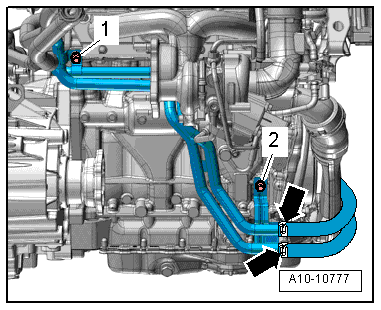

| Vehicles with auxiliary heater: |

| –

| Disconnect coolant hoses -arrows- and drain off remaining coolant. |

Note | A decisive factor of the effectiveness of the coolant is the amount of water used for mixing. Due to the different contents in the various countries that may even deviate locally, Volkswagen has decided to define the quality of the water to be used in the coolant system. Purified water fulfils all requirements. It is therefore recommended that purified water is mixed with the coolant whenever an older model's coolant is toped up or replaced. On newer vehicle models (model year 2010 ►), the use of purified water is absolutely essential. |

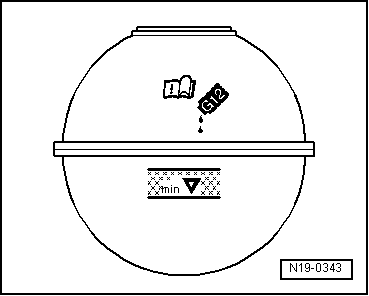

Caution | It is only permissible to use purified water for mixing with G12 plus-plus. The use of purified water ensures optimum protection against corrosion. |

|

Note | t

| Only use antifreeze additive G 12 plus-plus according to specification TL VW 774 G. |

| t

| Anti freeze additives with the indication „according to TL VW 774 G“ avoid damage due to corrosion, freezing or lime sedimentation. They also increase the boiling temperature of the liquid coolant. For this reason, the cooling system must be filled with coolant additive all year round. |

| t

| Thanks to this rise in the boiling point, the coolant guarantees good running, even when the engine undergoes heavy strain, especially in countries with tropical climates. |

| t

| The antifreeze protection must be guaranteed to approx. - 25 ºC (down to approx. -35°C in countries with arctic climate). |

| t

| The concentration of the coolant must not be reduced by adding water in summer or in countries with hot climates. The amount of anti-freeze in the coolant must be at least 40 %. |

| t

| If the climate requires a stronger anti-freeze, the anti-freeze agent can be increased, but only up to 60% (anti-freeze protection down to approx. -40ºC). If the proportion is greater, the cooling and anti-freeze protection capacity is reduced. |

| t

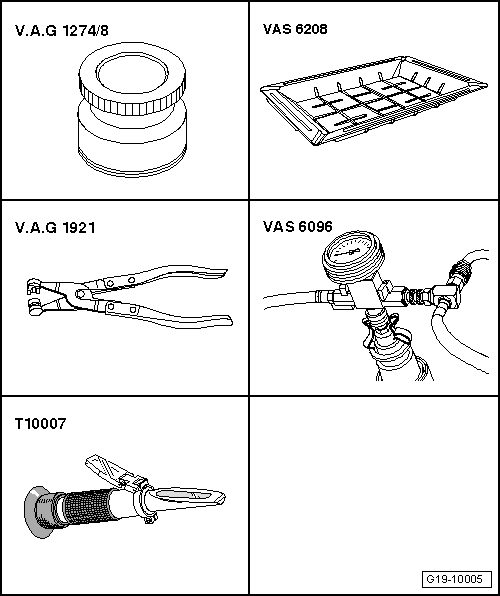

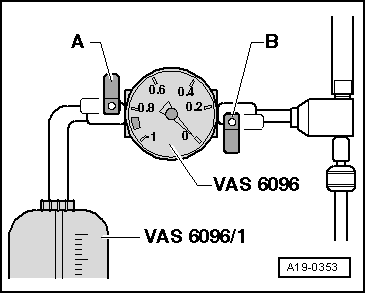

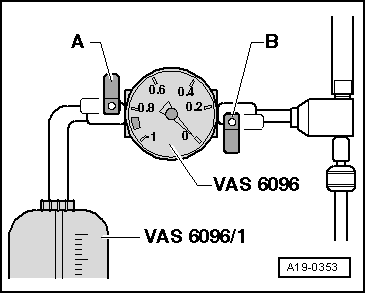

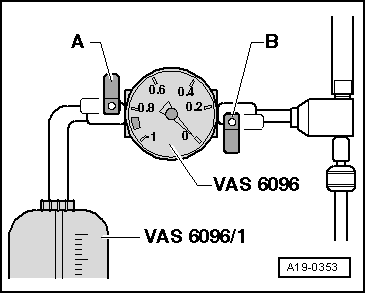

| The refractometer -T10007- is recommended for determining the current anti-freeze density. |

| t

| If radiator, heat exchanger, cylinder head or cylinder head gasket has been replaced, do not reuse old coolant. |

| Recommended mixture ratios: |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

WARNING

WARNING Caution

Caution