Leon Mk1

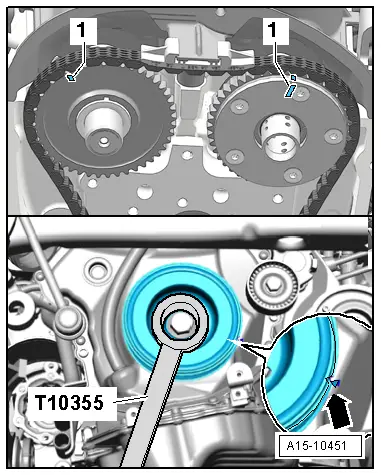

| Removing and fitting the distribution chain |

| Special tools and workshop equipment required |

| t | Locking pin -T10060 A- |

| t | Counterhold tool -T10355- |

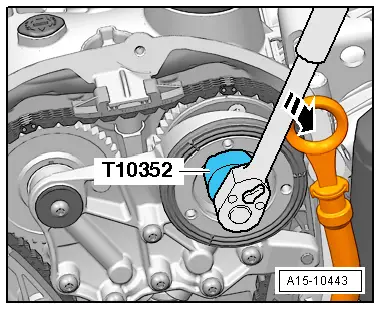

| t | attachment tool -T10352/1- |

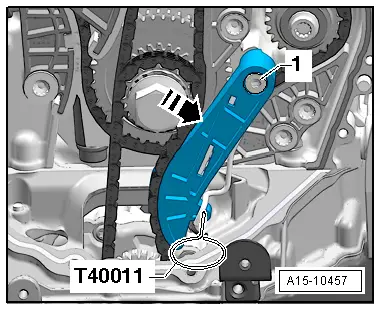

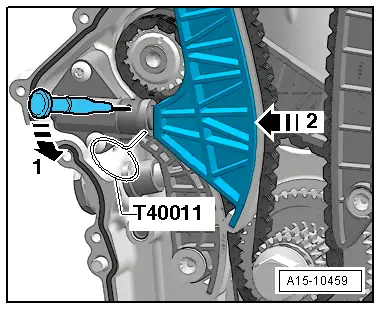

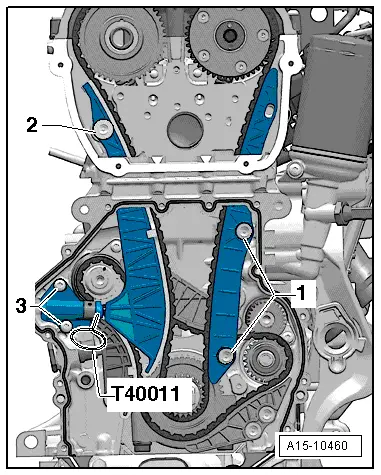

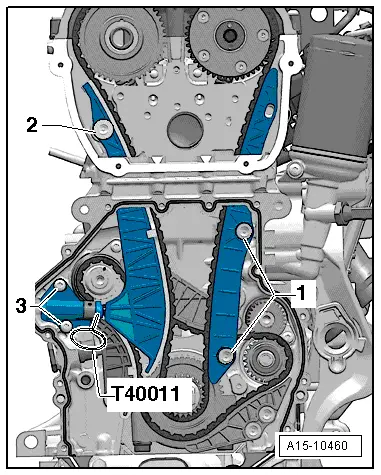

| t | Locking pin -T40011- |

| t | Torque wrench -V.A.G 1331- |

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

|

|

|

|

Caution

Caution