| –

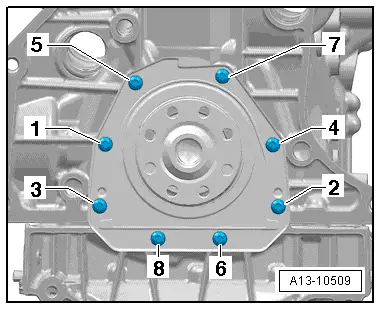

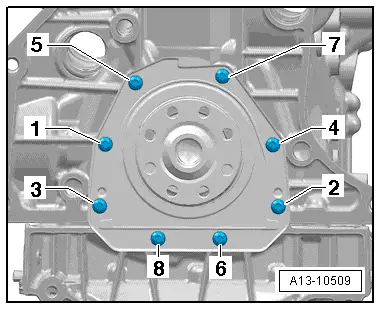

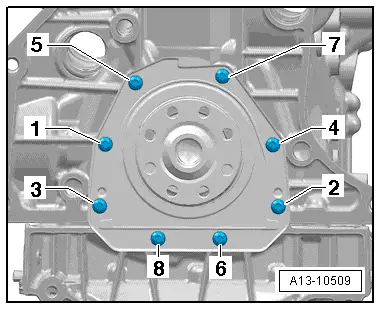

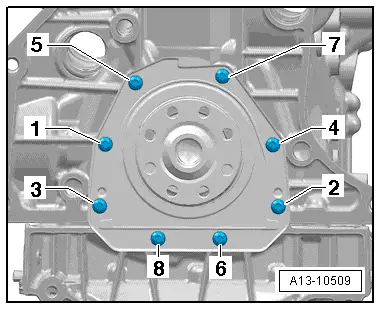

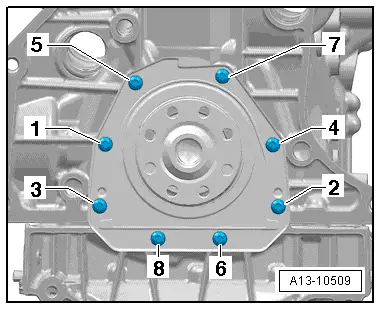

| Remove bolts -1 ... 8-. |

| –

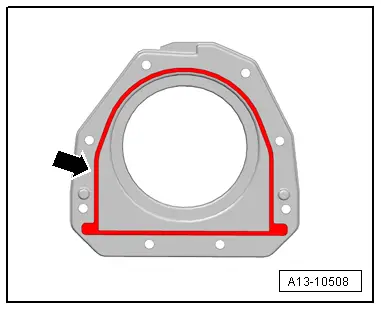

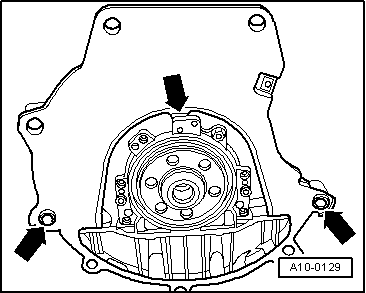

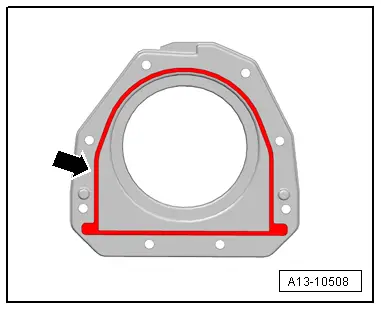

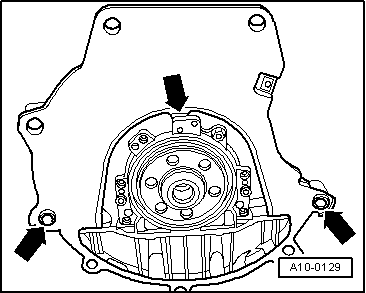

| Remove sealing flange (gearbox end). |

Note | t

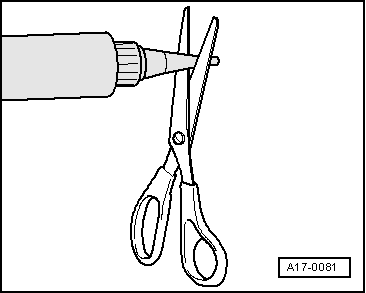

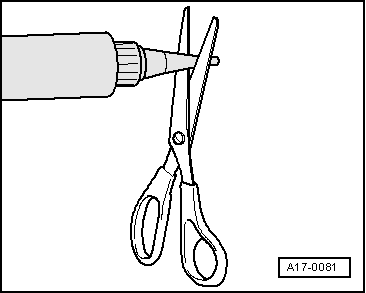

| Note the expiry date of the silicone sealant. |

| t

| The sealing flange must be installed within 5 minutes of applying silicone sealant. |

| t

| The bead of sealant must not be thicker than specified, otherwise excess sealant can enter the sump and obstruct the strainer in the oil intake pipe. |

| t

| After installing the sealing flange, wait about 30 minutes for the sealant to dry. Only then should the engine be refilled with oil. |

| –

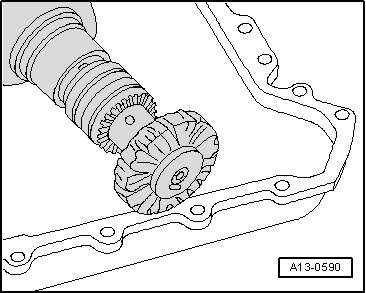

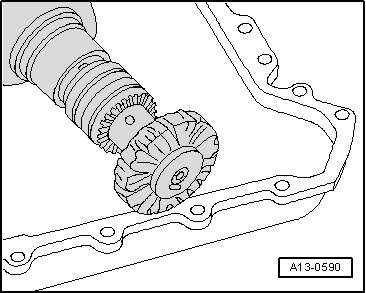

| Remove sealant remaining on cylinder block with flat scraper. |

WARNING |

|

|

|

Note

Note

Note

Note