| –

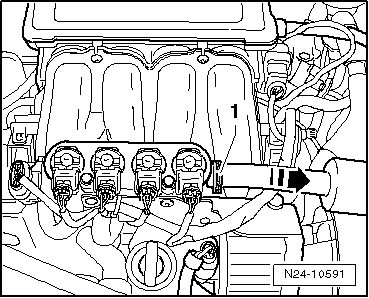

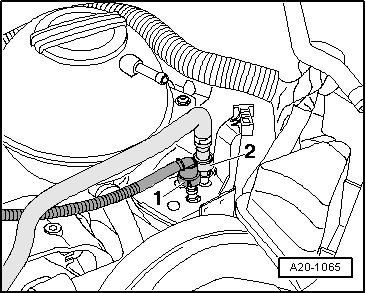

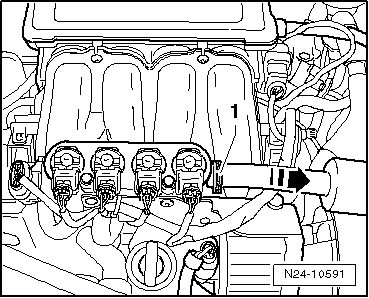

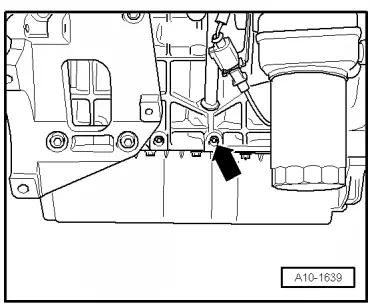

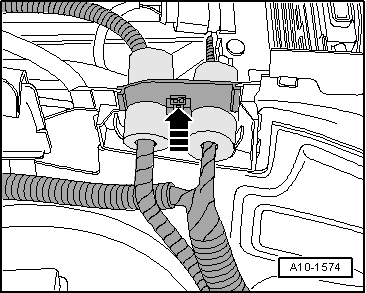

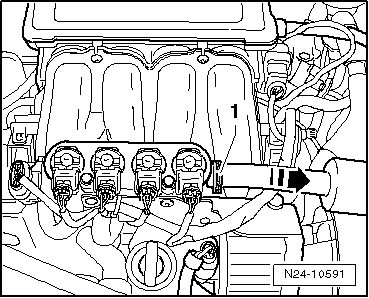

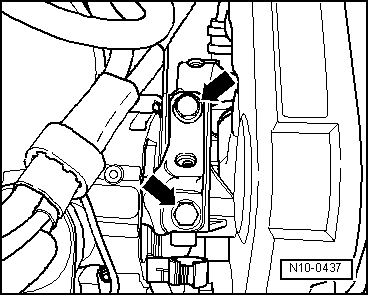

| Loosen the bracket -1- and remove the hose from the gas distribution rail -in the direction of the arrow-. |

| –

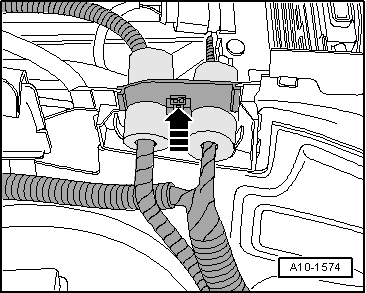

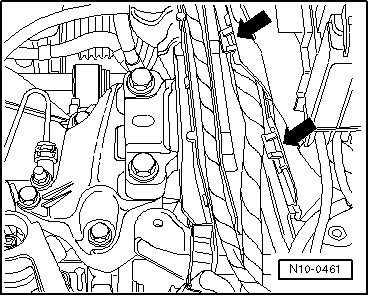

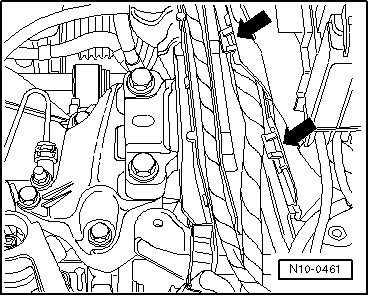

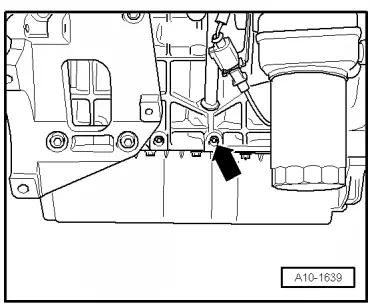

| Disconnect / separate all other electrical connections from engine and gearbox as necessary and lay to one side. |

| –

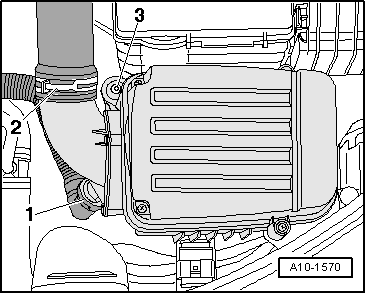

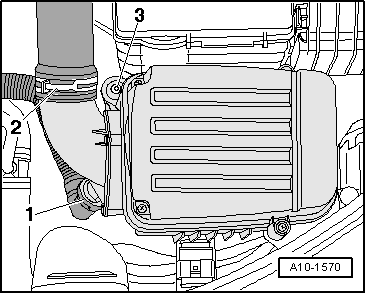

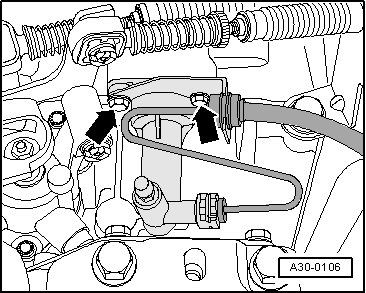

| Disconnect all other coolant, vacuum and intake hoses from the engine. |

| Vehicles with air conditioner: |

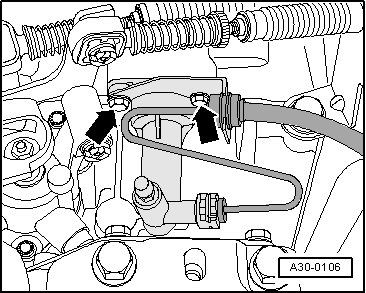

Note | In order to avoid damage to the condenser or the lines of the refrigerant, take care that pulling, bending or excessive twisting of the line is avoided. |

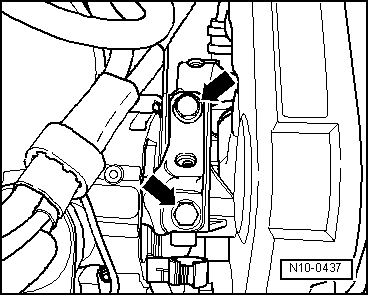

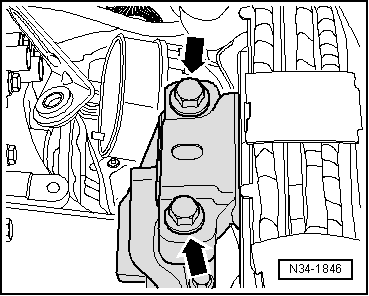

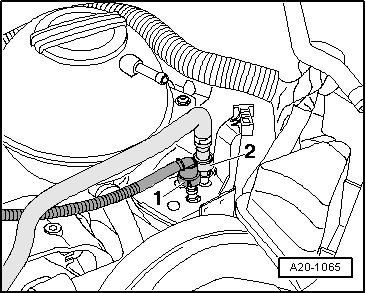

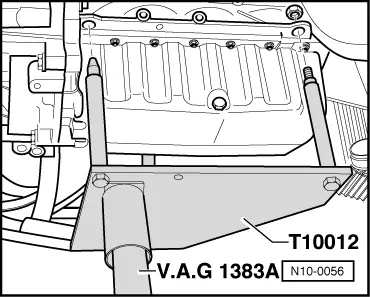

| Remove the engine without opening the refrigerant circuit: |

| –

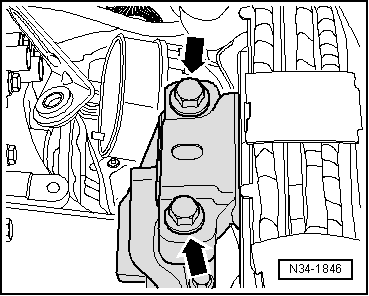

| Attach the compressor to the lock carrier plate so that the refrigerant lines are not under any strain. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note