Note | Please observe requirements for disposal. |

| –

| Unscrew the gearbox and oil sump fixing bolts. |

| –

| Disconnect the connector from the oil level and temperature sender -G266-. |

| –

| Loosen the oil sump bolts on the flywheel side of the engine with the articulated wrench e/c 10 -3185-, and remove them with the socket -T10058-. |

| –

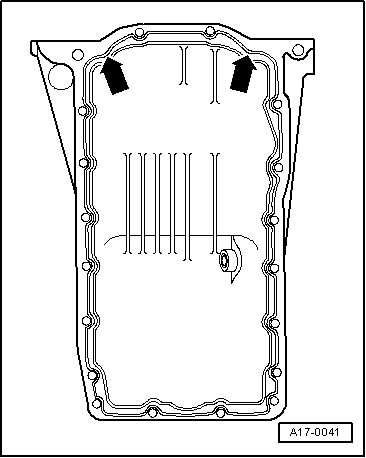

| Loosen the remaining bolts, and remove the oil sump. If necessary, release the oil sump by tapping it gently with a rubber hammer. |

Note | t

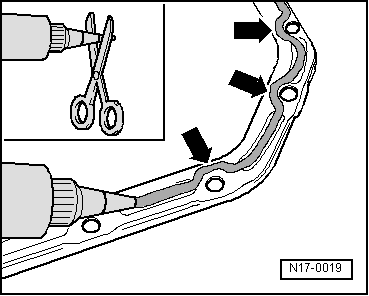

| Observe use-by date of sealant. |

| t

| The oil sump should be fitted into place 5 minutes after the application of the sealant. |

|

|

|

Note

Note Note

Note Note

Note

Note

Note