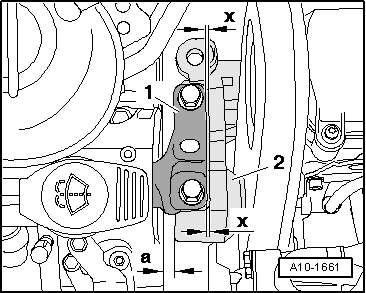

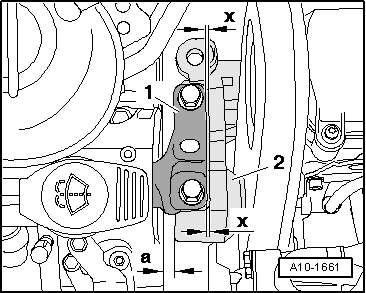

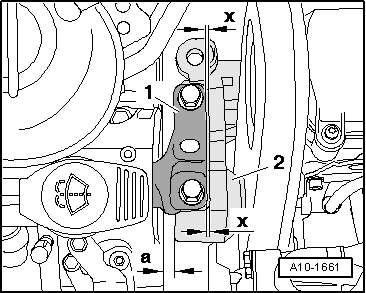

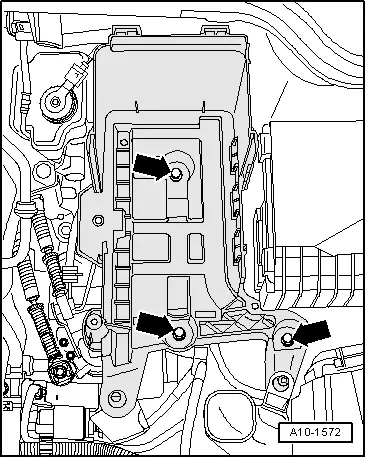

| The following dimensions must be reached: |

| l

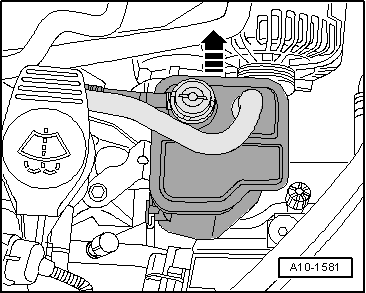

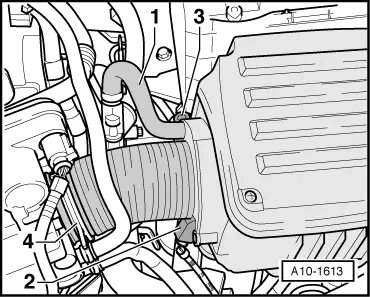

| Between the engine support and the right longitudinal member there must be a distance of -a- = 16 mm. |

| l

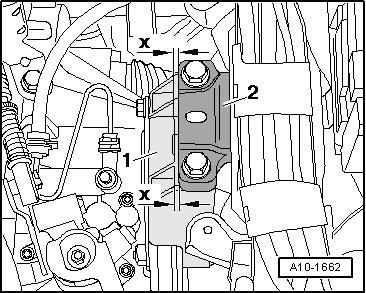

| The moulded edge at the engine support foot -2- must be parallel to the support arm -1- (dimension-x- = dimension-x-). |

Note | The dimension -a- = 16 mm. can be checked, for example, with an appropriate cylindrical object. |

| If the gap is too narrow or too wide, proceed as follows → Anchor . |

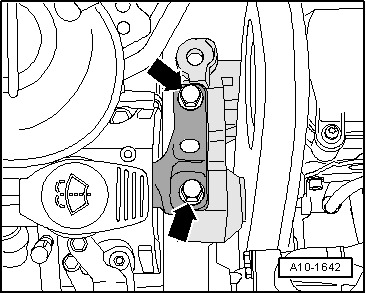

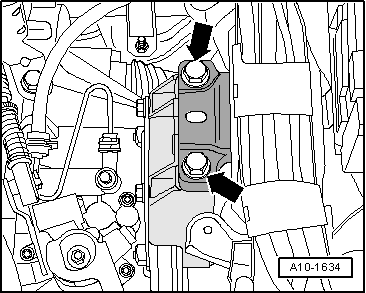

| Assembly mounting: adjusting |

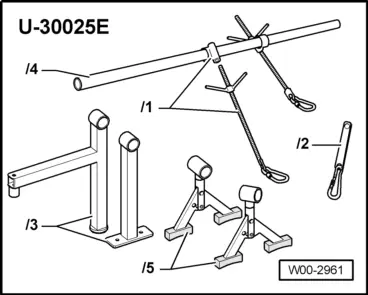

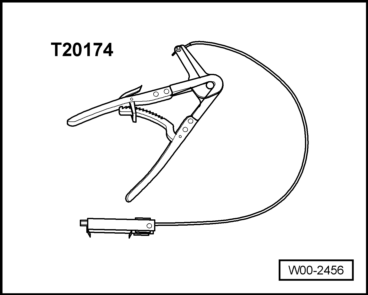

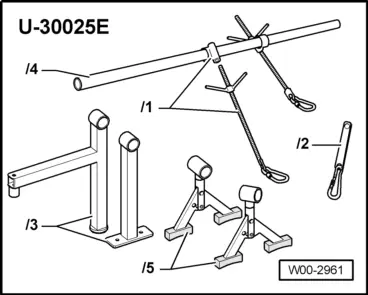

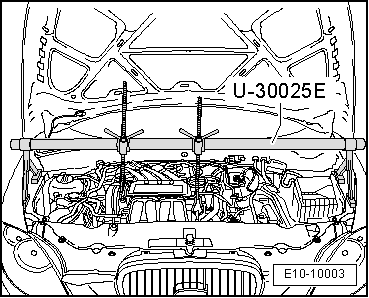

| Special tools and workshop equipment required |

|

|

|

Note

Note

Note

Note