| –

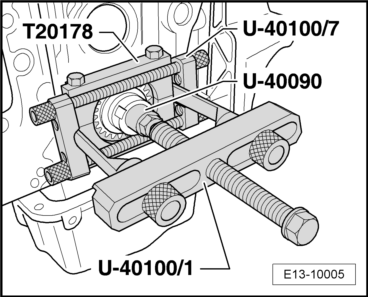

| Remove the crankshaft gear with the set -U-40100A- with adapter -U-40100/PP- and use the key -U-40090- to protect the crankshaft pin key. Attach adapter -U-40100/7- as shown in illustration for safety and to achieve a compact unit. |

| Continue the installation in the reverse order of removal sequence, observing the following: |

WARNING |

| –

| Heat the chain sprocket in the oven for about 15 minutes at 220 ºC. |

| l

| Installation location: The wide edge of the sprocket points to the engine. |

| –

| Fit chain sprocket on crankshaft axle using pliers. |

|

|

|