Leon Mk1

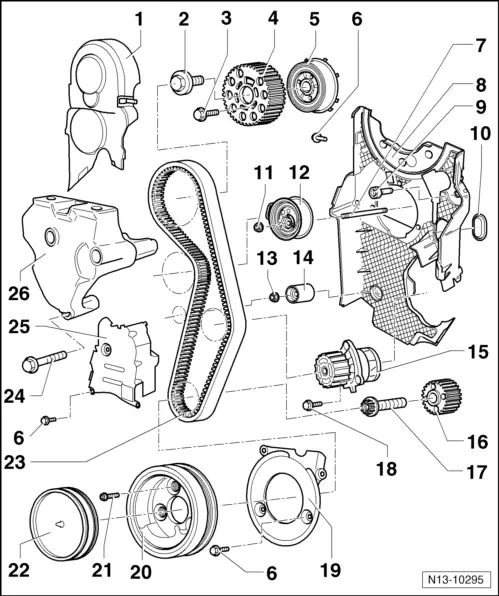

| Timing belt mechanism, list of components. |

| 1 - | Upper protection element for the notched belt |

| 2 - | 100 Nm |

| 3 - | 25 Nm |

| 4 - | Camshaft wheels |

| 5 - | Hub |

| q | With generator wheel |

| q | Use counterhold tool -T10051- to loosen and tighten. |

| q | To remove, use puller -T10052A-. |

| q | Removing and installing → Chapter |

| 6 - | 10 Nm |

| q | Replace |

| 7 - | Stud |

| q | 15 Nm |

| 8 - | Toothed belt cover (rear) |

| 9 - | 25 Nm |

| 10 - | Sleeve |

| q | Replace if damaged |

| 11 - | 20 Nm + 45° (1/8 turn) |

| q | Use the correct tightening torque to avoid damages to the engine. |

| 12 - | Tensioning roller |

| 13 - | 20 Nm |

| 14 - | Idler roller |

| 15 - | Coolant pump |

| q | Removing and installing → Chapter |

| 16 - | Crankshaft sprocket |

| 17 - | 120 Nm + 90° (1/8 turn) |

| q | Replace |

| q | Use counterhold tool -T20018B- to loosen and tighten. |

| q | Do not additionally oil or grease the threads and shoulder |

| q | Tightening can be done in several stages |

| 18 - | 15 Nm |

| 19 - | Notched belt guard - lower part |

| 20 - | Belt pulley and vibration damper |

| q | Can only be installed in one position. Holes are off-set |

| 21 - | 10 Nm + 90° (1/8 turn) |

| q | Replace |

| 22 - | Cover |

| 23 - | Notched belt |

| q | Mark direction of rotation before removing. |

| q | Check for wear |

| q | Do not kink |

| q | Removing and installing → Chapter |

| 24 - | 40 Nm +1/2 turn further (180º) |

| q | Replace |

| 25 - | Notched belt guard - centre part |

| 26 - | Engine mounting |

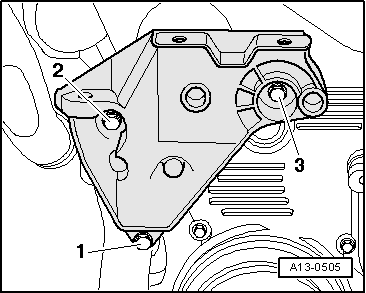

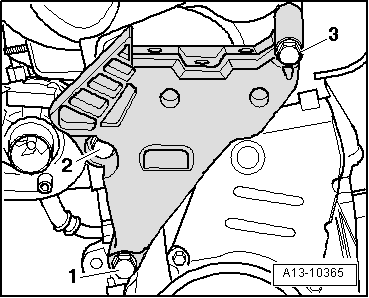

| Different procedures: |

| q | Small engine support foot → Fig. |

| q | Large engine support foot → Fig. |

|

|

| 1. phase |

| ||

| 2. phase |

| ||

| 3. phase |

|

|

|

| 1. phase |

| ||

| 2. phase |

| ||

| 3. phase |

|