Leon Mk1

|

| Consult the equivalence table for tools and equipment according to applicability among Seat / VW / Audi / Skoda → Chapter. |

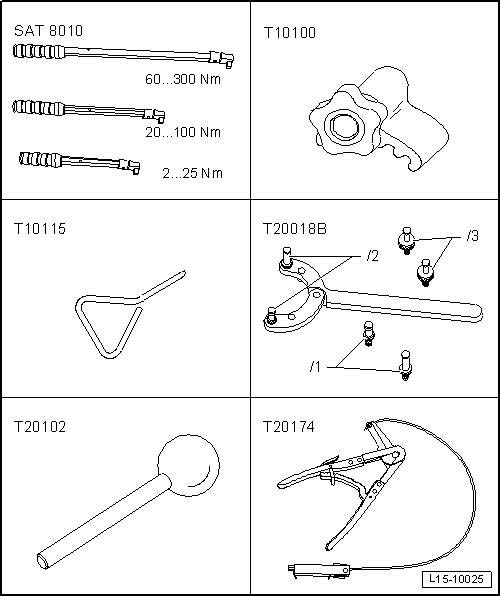

| Special tools and workshop equipment required |

| t | Torque wrench kit -SAT 8010-, see equivalent → Anchor |

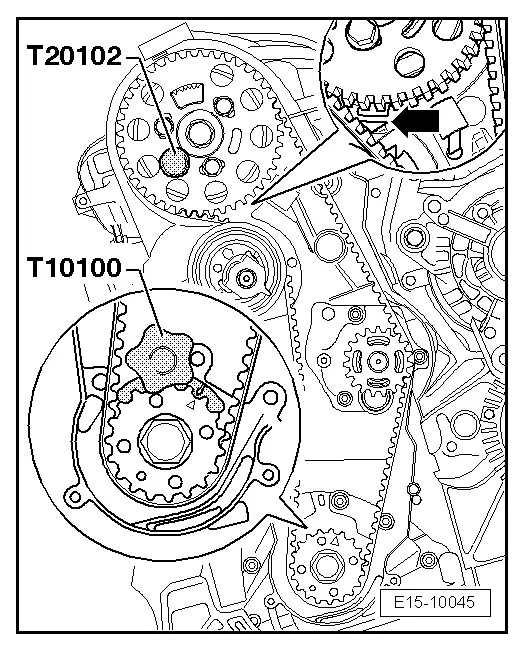

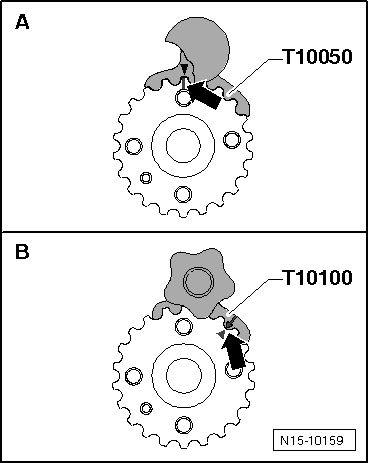

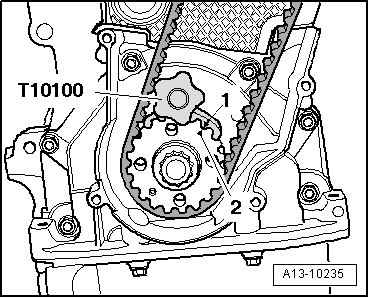

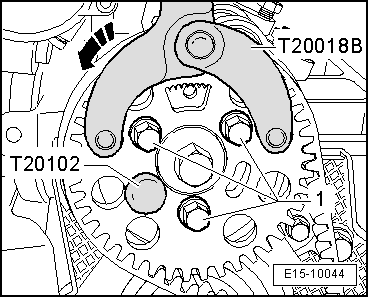

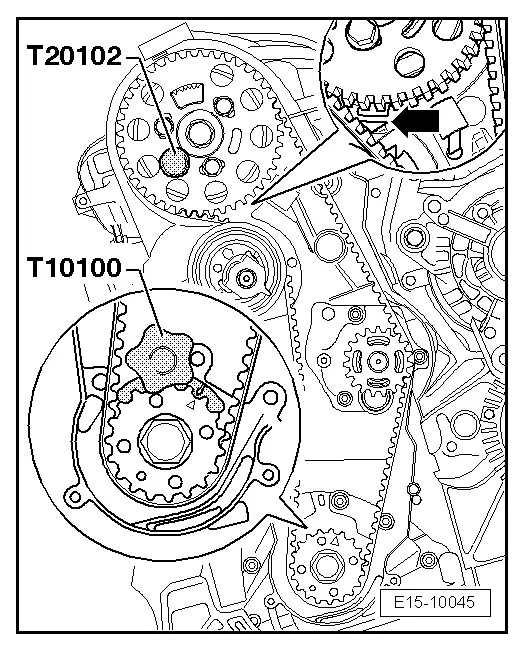

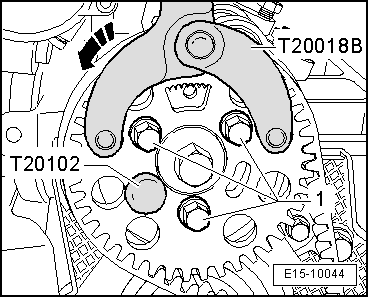

| t | counterhold -T10100-, see equivalent → Anchor |

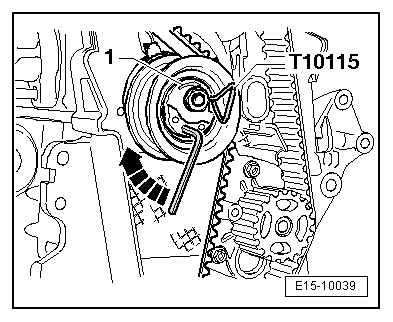

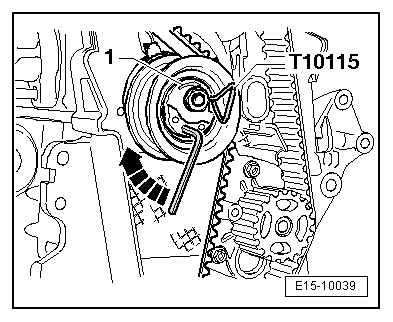

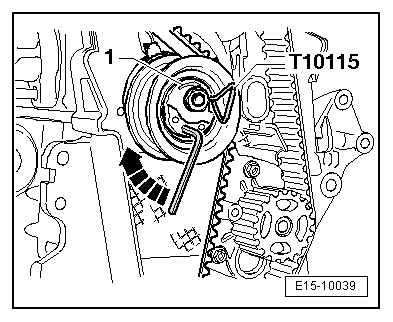

| t | Hose clamp -T10115-, see equivalent → Anchor |

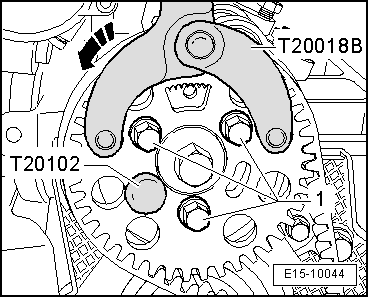

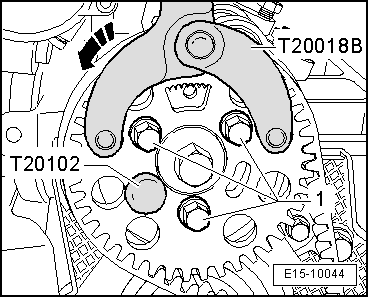

| t | Hose clamp -T20018B-, see equivalent → Anchor |

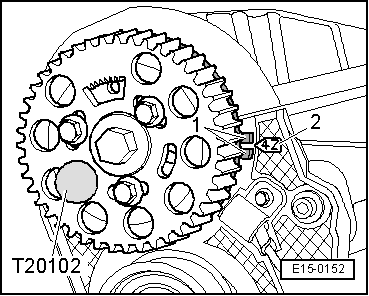

| t | Hose clamp -T20102-, see equivalent → Anchor |

| t | Base -T20174-, see equivalent → Anchor |

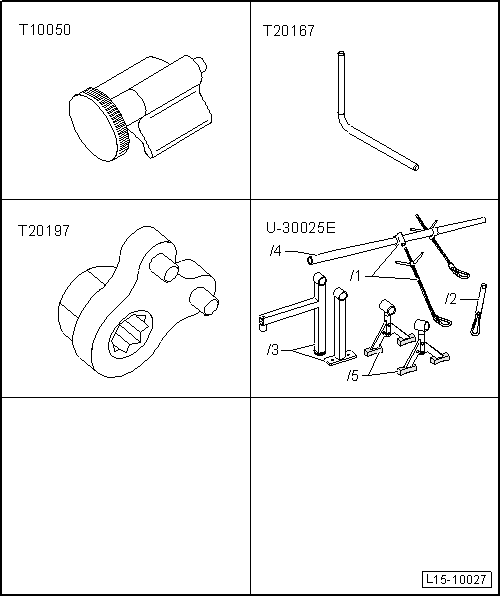

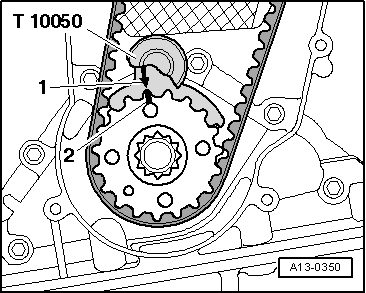

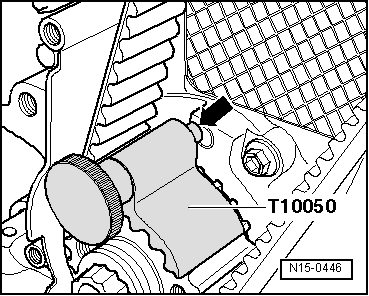

| t | Hose clamp -T10050-, see equivalent → Anchor |

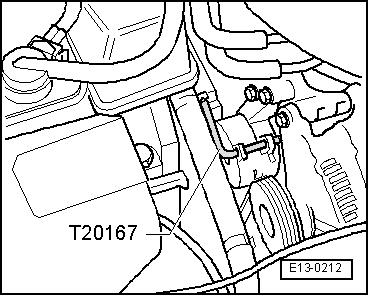

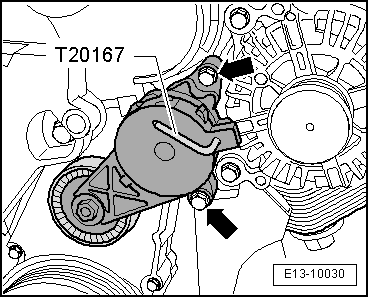

| t | Hose clamp -T20167-, see equivalent → Anchor |

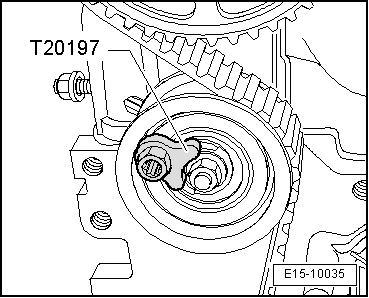

| t | Turning tool -T20197-, see equivalent → Anchor |

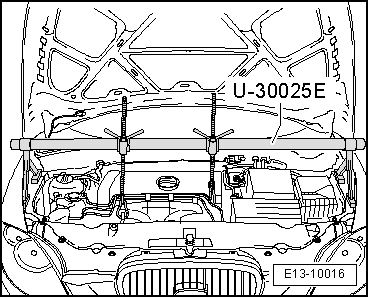

| t | Socket -U 30025E-, see equivalent → Anchor |

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note |

|

Note

Note

Note

Note |

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

WARNING

WARNING