Leon Mk1

|

| Consult the equivalence table for tools and equipment according to applicability among Seat / VW / Audi / Skoda → Chapter. |

| Special tools and workshop equipment required |

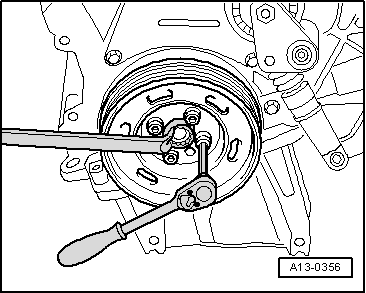

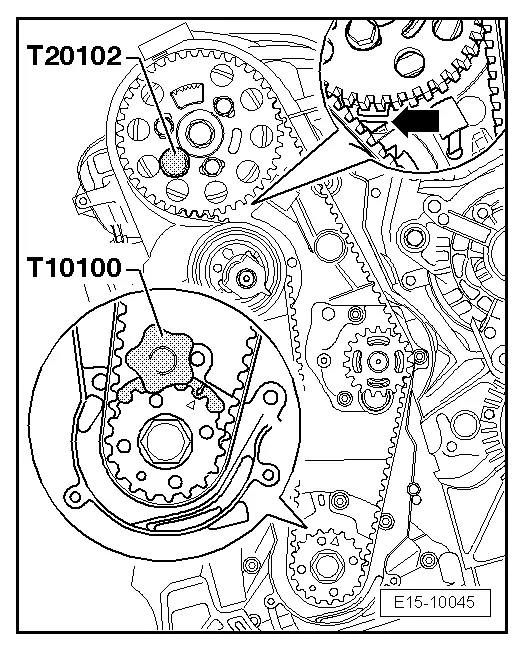

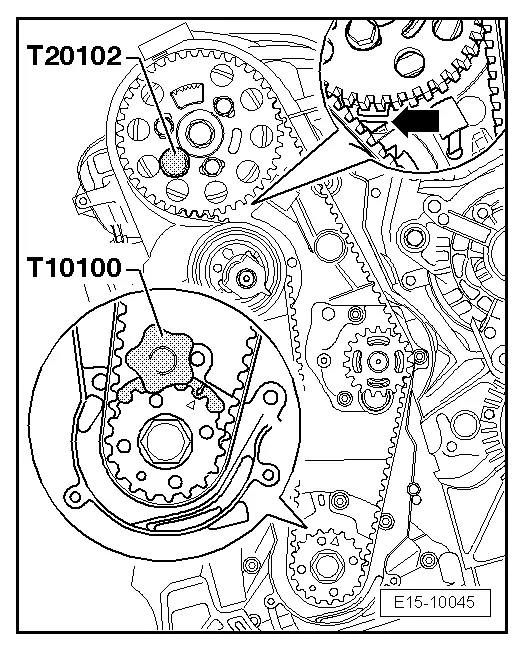

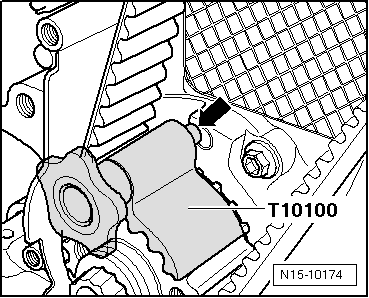

| t | counterhold -T10100-, see equivalent → Anchor |

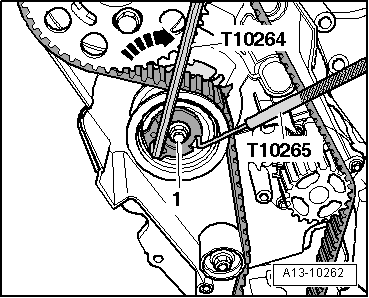

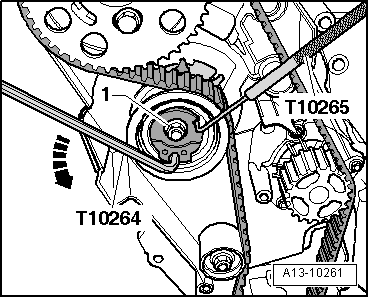

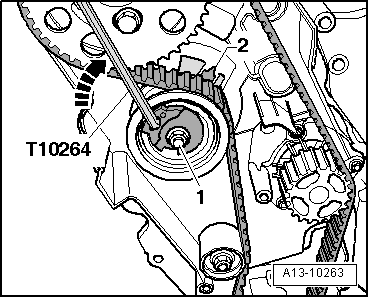

| t | Spanner -T10264-, see equivalent → Anchor |

| t | Hose clamp -T10265-, see equivalent → Anchor |

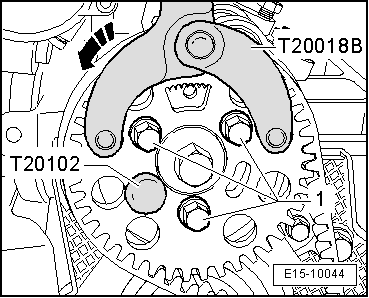

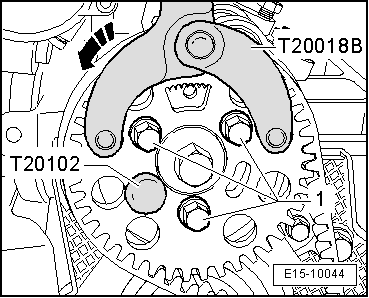

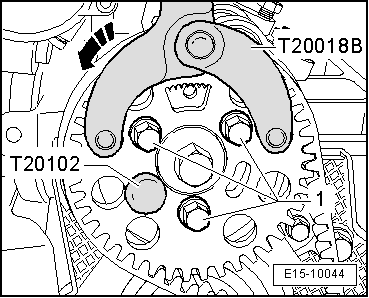

| t | Hose clamp -T20018B-, see equivalent → Anchor |

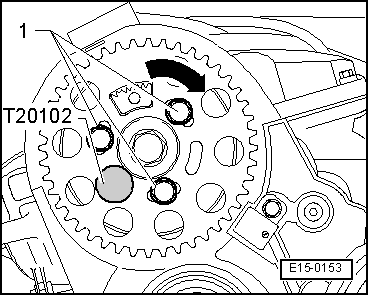

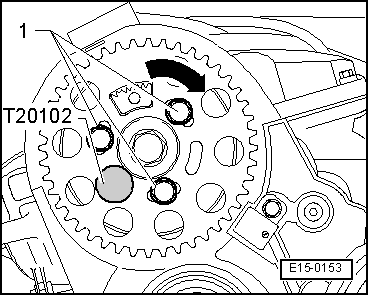

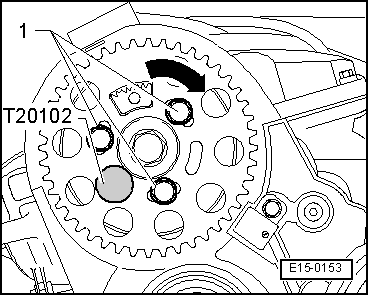

| t | Hose clamp -T20102-, see equivalent → Anchor |

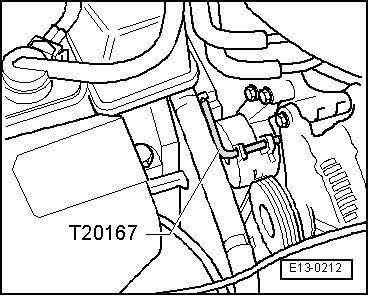

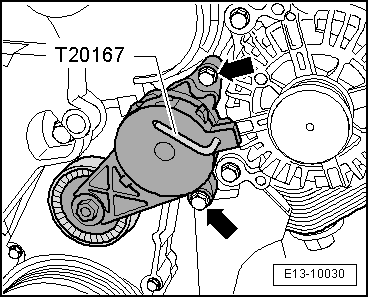

| t | Hose clamp -T20167-, see equivalent → Anchor |

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note |

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note |

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Component | Nm | |

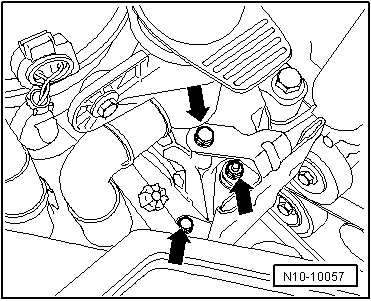

| Notched belt tensioning roller to cylinder head | 20 + 45° → Remark | |

| Camshaft pinion to bin | 25 | |

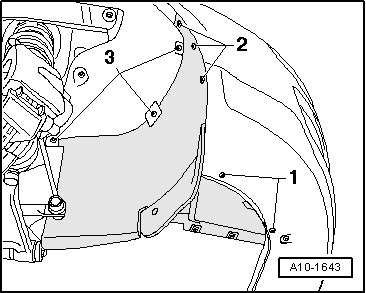

| Bottom section of notched belt guard to cylinder block | 10 → Remark | |

| Centre section of notched belt guard to cylinder block | 10 → Remark | |

| Vibration damper to the crankshaft wheel | 10 + 90° → Remark → Remark | |

| Engine support to cylinder block | 40 + 180° → Remark → Remark | |

| Engine support to body | 40 + 90° → Remark → Remark | |

| Connection to engine console/body | 20 + 90° → Remark → Remark | |

| Pendulum support to sub-frame | 100 + 90° → Remark → Remark | |

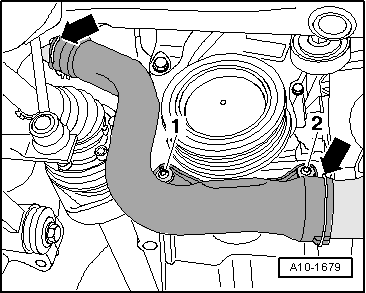

| Front supercharger air tube to the engine block | 22 | |

|

WARNING

WARNING