Leon Mk1

|

| Consult the equivalence table for tools and equipment according to applicability among Seat / VW / Audi / Skoda → Chapter. |

| Special tools and workshop equipment required |

| t | Torque wrench kit -SAT 8010-, see equivalent → Anchor |

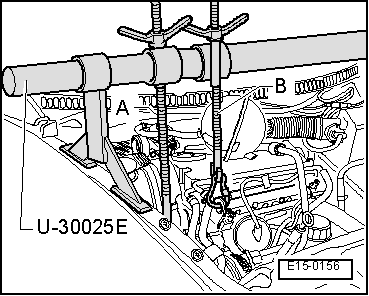

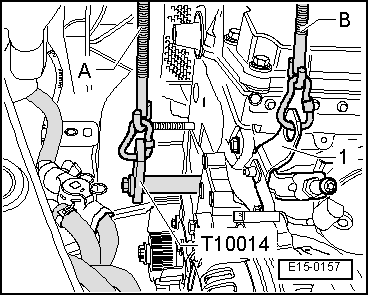

| t | Bracket -T10014- (only for vehicles ► 05.05 with small engine support), see equivalent → Anchor |

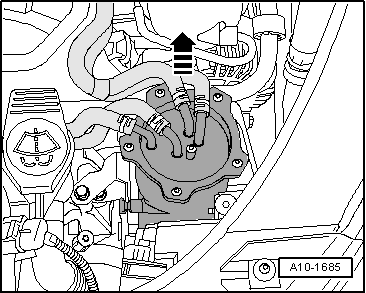

| t | counterhold -T10100-, see equivalent → Anchor |

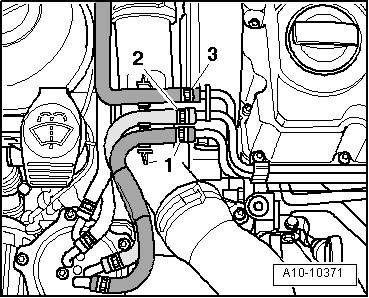

| t | Hose clamp -T10051-, see equivalent → Anchor |

| t | Extractor -T10052A-, see equivalent → Anchor |

| t | Hose clamp -T10115-, see equivalent → Anchor |

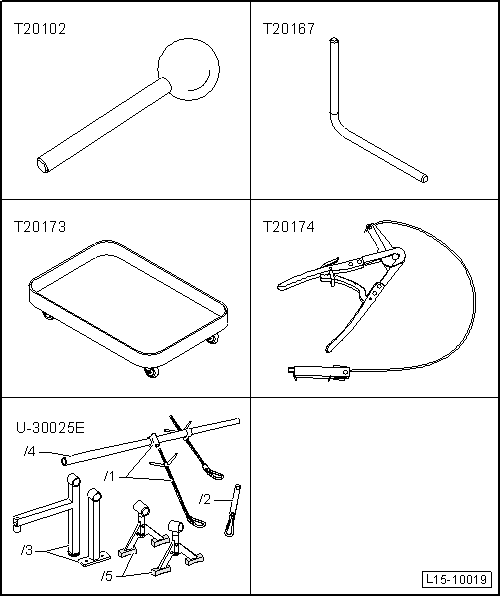

| t | Hose clamp -T20102-, see equivalent → Anchor |

| t | Hose clamp -T20167-, see equivalent → Anchor |

| t | Collecting tray -T20173-, see equivalent → Anchor |

| t | Base -T20174-, see equivalent → Anchor |

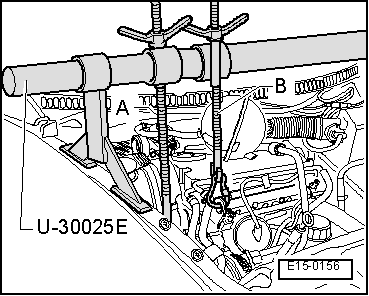

| t | Bracket -U 30025E- (only for vehicles ► 05.05 with small engine support), see equivalent → Anchor |

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

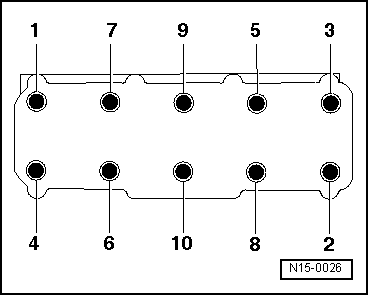

| stage: | Tighten | ||

| I |

| ||

| II |

| ||

| III |

| ||

| IV |

|

Note

Note

|

|

|

|

|

Note

Note

|

|

| Component | Nm | |

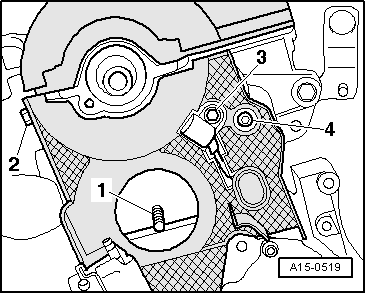

| Notched belt rear protection to cylinder head | 10 → Remark | |

| Hall sender to the cylinder head | 10 → Remark | |

| Pin to cylinder head | 15 | |

| Hub to the camshaft | 100 | |

| Oil pressure switch to oil filter bracket | 20 | |

| Oil supply pipe to the turbocharger | 22 | |

| Oil supply pipe to oil filter bracket | 22 | |

| Oil return pipe to the engine block | 30 | |

| Bracket | to turbocharger | 20 |

| Turbocharger | To engine block | 40 |

| Front air hose | To engine block | 15 |

| to bracket | 8 | |

|

| Component | Nm | ||

| Hall sender -G40- to the cylinder head | 10 → Remark | ||

| Notched belt rear protection to cylinder head | M6 | 10 → Remark | |

| M8 | 25 → Remark | ||

| Hub to the camshaft | 100 | ||

| Centre section of notched belt guard to cylinder block | 10 → Remark | ||

| Bottom section of notched belt guard to cylinder block | 10 → Remark | ||

| Exhaust gas recirculation radiator to intake manifold | 22 | ||

| Turbocharger support to | Turbocharger | 25 | |

| cylinder block | 60 | ||

| Oil return pipe to the turbocharger | 15 | ||

| Exhaust gas recirculation joint hose | exhaust gas recirculation radiator | 22 | |

| Exhaust manifold | 25 | ||

| Front crosspiece of the vehicle to the bodywork | 22 | ||

| Heat shield to cylinder block | 35 | ||

| Ribbed belt tensioner to ancillaries bracket | 23 | ||

| Guide tube for the dipstick to | Oil filter bracket | 10 | |

| Attachment ring | 10 | ||

| Support for the oil supply pipe | 10 | ||

| Oil supply pipe to oil filter bracket | 22 | ||

| Oil pressure switch to oil filter bracket | 20 | ||

| Right air hose to bracket | 8 | ||

|

WARNING

WARNING