| –

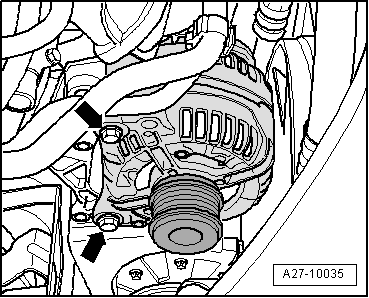

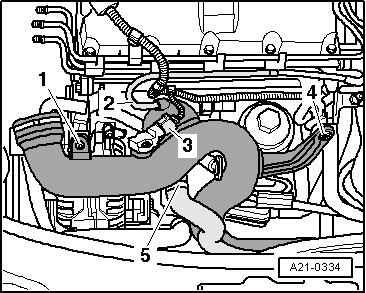

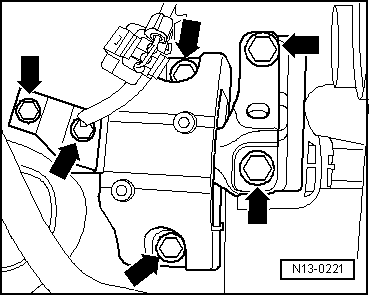

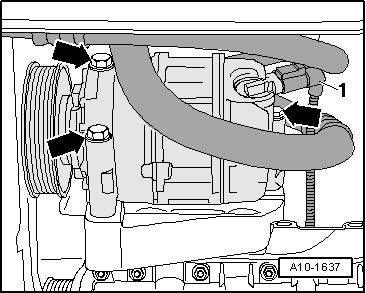

| Screw out bolts -arrows- and remove alternator. |

| –

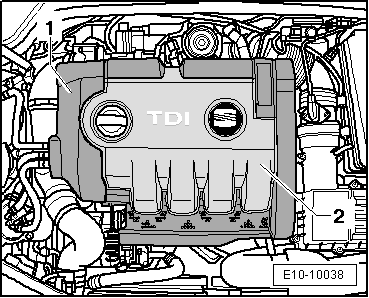

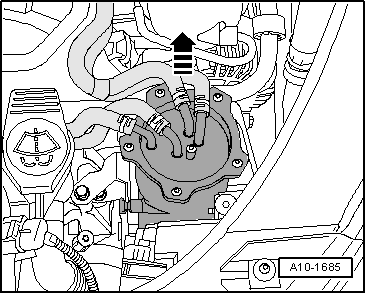

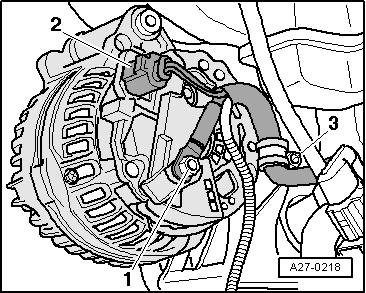

| Remove alternator upwards. |

Note | t

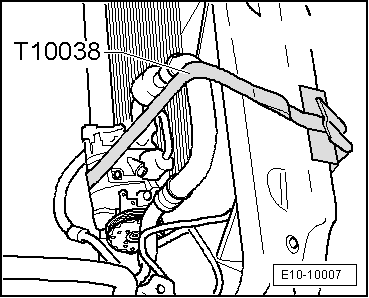

| If the alternator is stuck on its support, tighten the fixing screw 2 turns less. |

| t

| Carefully tap the bolt heads with the flat side of the hammer (in this manner you release the alternator fixing clamps). |

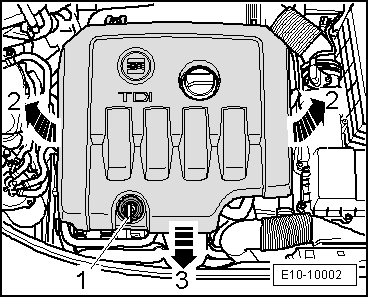

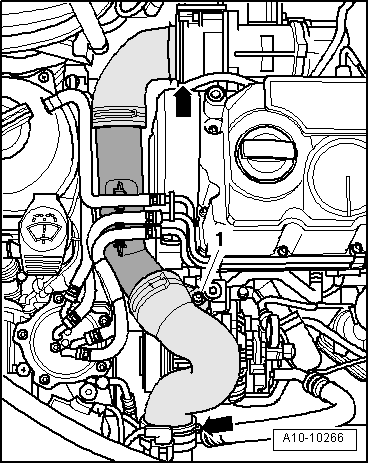

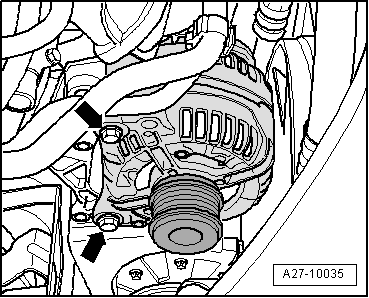

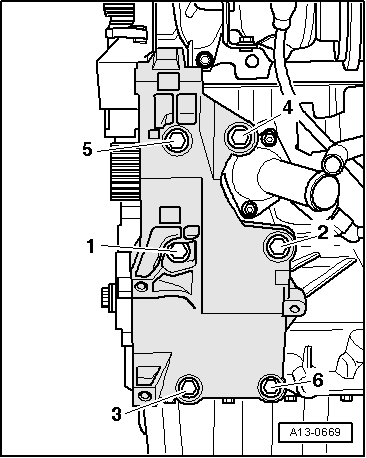

WARNING | The air conditioning refrigerant circuit must not be opened. |

|

Note | To prevent damage to the air conditioning compressor and refrigerant pipes/hoses, ensure that the pipes and hoses are not stretched, kinked or bent. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

WARNING

WARNING