Leon Mk1

|

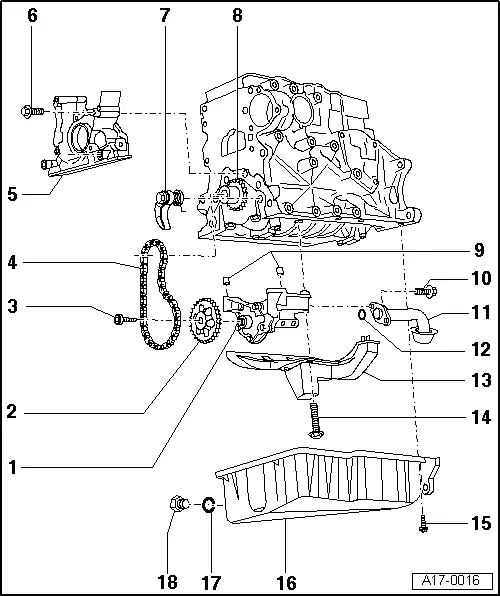

| 1 - | Oil pump: |

| q | With 12 bar pressure relief valve |

| q | removing and fitting → Chapter |

| q | Before installing, check that the two dowel sleeves → Item for centring oil pump/cylinder block are fitted. |

| q | Renew pump if there is scoring on moving surfaces and gear teeth. |

| q | Tightening torque for oil pump cover to oil pump housing: 10 Nm |

| 2 - | Oil pump chain sprocket |

| q | Sprocket can only be fitted on oil pump shaft in one position. |

| 3 - | 20 Nm + 90° (1/4 turn) further |

| q | Replace. |

| 4 - | Chain for oil pump |

| q | For oil pump |

| q | Mark direction of rotation before removing. |

| q | Check for wear |

| 5 - | Front sealing flange: |

| q | Fit using silicon sealant → Chapter |

| q | Renewing crankshaft oil seal on pulley end → Chapter |

| 6 - | 15 Nm |

| 7 - | Chain tensioner |

| q | Tighten to 16 Nm |

| q | Do not dismantle |

| q | Note fitting position: |

| q | Pre-tension spring and engage before installing |

| q | If the spring is broken, replace the complete chain tensor |

| 8 - | Oil pump chain sprocket |

| q | removing and installing → Chapter |

| 9 - | Dowel sleeves |

| q | 2x |

| 10 - | 15 Nm |

| 11 - | Oil intake pipe |

| q | Clean strainer if dirty |

| 12 - | O-ring |

| q | Replace. |

| 13 - | Anti-surge valve |

| 14 - | 16 Nm |

| 15 - | 15 Nm |

| 16 - | Oil sump |

| q | removing and fitting → Chapter |

| 17 - | Seal |

| q | Replace. |

| 18 - | Oil drain plug - 30 Nm |

|

|

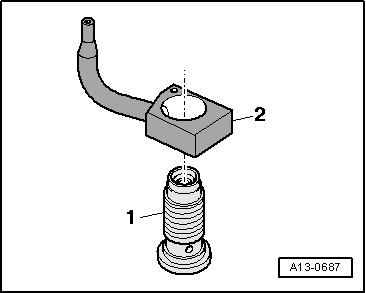

| 1 - | Seal bolt -25 Nm |

| 2 - | Seal |

| q | Replace. |

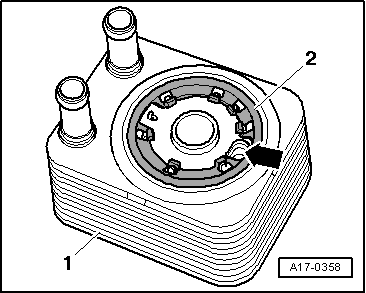

| 3 - | Oil cooler |

| q | See note → Anchor |

| q | Coolant hose schematic diagram → Chapter. |

| 4 - | Seal |

| q | Replace. |

| q | Installation position → Fig. |

| 5 - | 14 Nm + 90° (1/4 turn) further |

| q | Replace. |

| q | Tighten diagonally |

| 6 - | Seal |

| q | Replace. |

| 7 - | Oil filter bracket |

| q | With oil retainer valve |

| q | The oil check valve cannot be replaced separately |

| 8 - | Seal |

| q | Replace. |

| 9 - | Oil pressure switch -F1- -20 Nm |

| q | 0.7 bar - brown |

| q | testing → Chapter |

| 10 - | Trim cap, -25 Nm |

| q | Depending on version: Wrench -T20160- e/c 36 mm or universal socket wrench -e/c 32 mm- |

| 11 - | O-ring |

| q | Replace. |

| 12 - | Oil filter cartridge |

| q | Remove seal bolt → Item |

| q | When replacing the oil filter, replace the O-rings → Item and → Item |

| q | Note fitting position: |

| q | Heed replacement intervals → Booklet1 |

| 13 - | O-ring |

| q | Replace. |

| 14 - | Oil supply line |

| q | Tighten to 22 Nm |

| q | to turbocharger |

| q | Note the installation sequence: |

| – | Screw in first the two ends of the conduit and leave them loose |

| – | Then, carry out a final tightening of the two conduction ends. |

| – | Finally, secure the bracket. |

| 15 - | Joint mouth |

| 16 - | Seal |

| q | Replace. |

|

|