| –

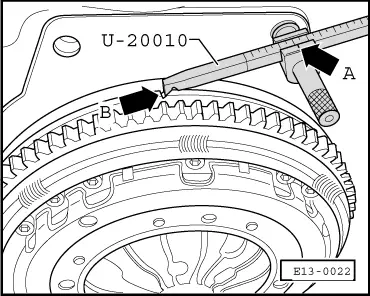

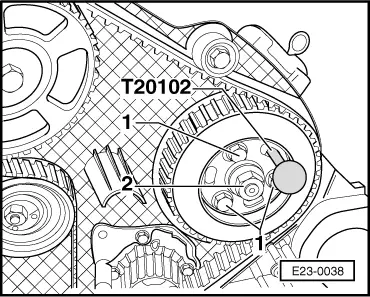

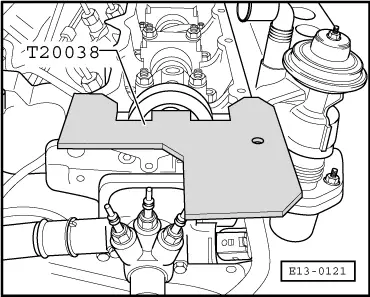

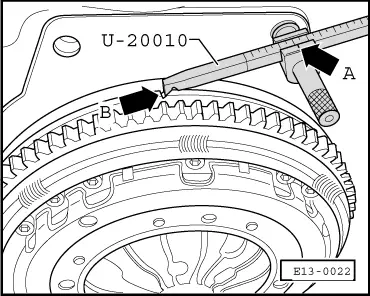

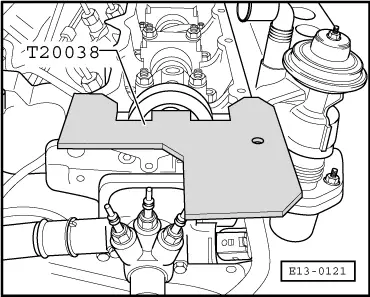

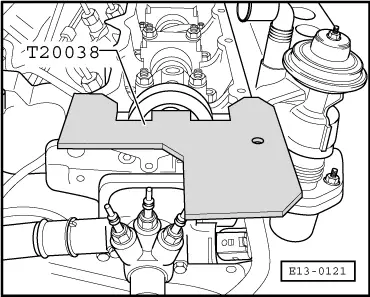

| Immobilise the camshaft using the timing adjustment tool -T20038-. |

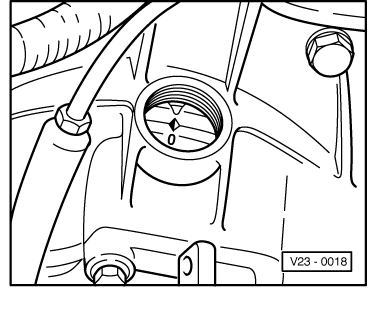

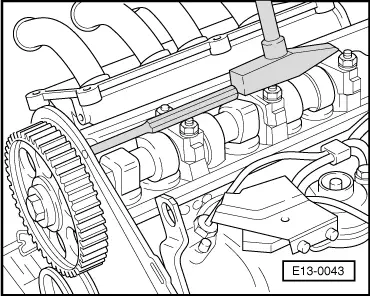

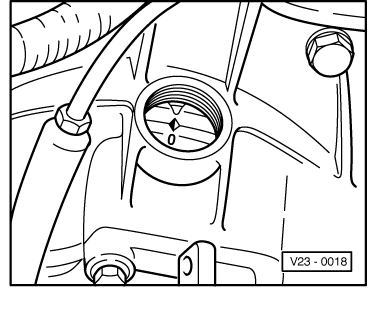

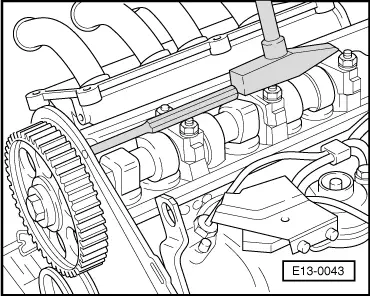

| Centre the adjustment tool as follows: |

| –

| Once the camshaft has been immobilised, turn it until the end of the ruler stops at the cylinder head. Measure the resulting play on the other end of the ruler using a thickness gauge. Insert a gauge with the play reduced by half between the ruler and the cylinder head. Then, turn the camshaft so that the ruler presses on the gauge. Insert a second gauge with the same measurement on the other end between the ruler and the cylinder head. |

| –

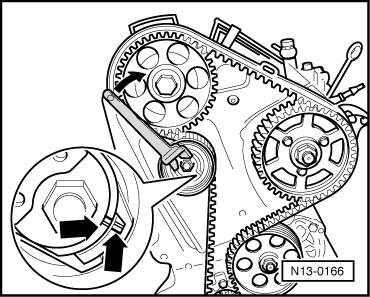

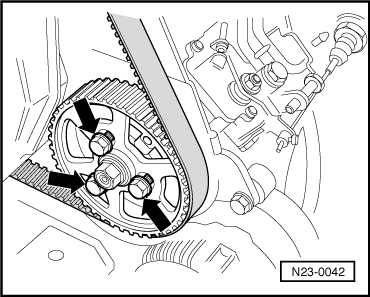

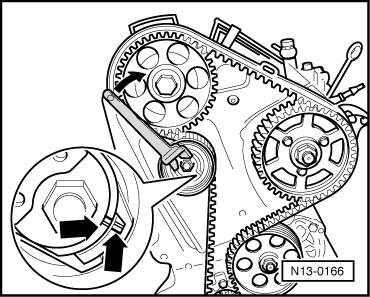

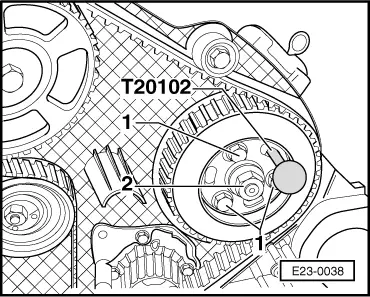

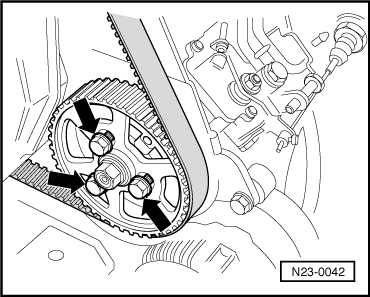

| Loosen by a 1/2 turn the attachment bolt of the camshaft cogwheel. |

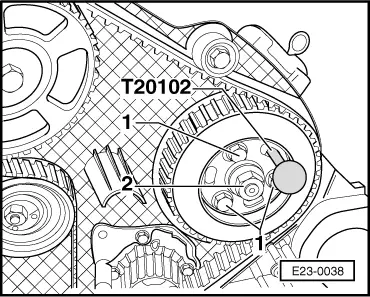

|

|

|