Note! | The equipment -V.A.G 1552- may be used instead of the -V.A.G 1551-, however in this case the results cannot be printed. |

| During the diagnostic, the actuators activate the following components in this order: |

| 1 - | Exhaust gas recirculation valve -N18- |

| 2 - | Indicator for preheat time -K29- |

| 3 - | Relay for glow plugs -J52- |

| 4 - | Full charge limit valve -N194- |

| 5 - | Injection commencement valve -N108- |

| 6 - | Idle acceleration valve -N177- (engines with air conditioning) |

Note! | t

| The actuator diagnostic can be carried out with the engine running or not. As the noise of the valves themselves can be appreciated more when the engine is stopped, it is better to carry out the test with the engine stopped. |

| t

| The diagnostic function work process of the actuation elements works using and activation signal followed by a deactivation signal. The message for each actuator appears twice. |

| t

| The actuator activation is limited to 30 seconds, however it is possible to terminate at any moment by pressing the key →. |

| t

| Before carrying out the diagnostic of the actuators, the ignition must be disconnected. |

| –

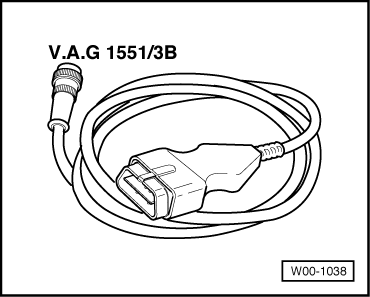

| Connect the equipment -V.A.G 1551- (V.A.G 1552) and, using the corresponding “address code” 41, select the diesel pump electronic control unit. While doing this, the engine must be running idle → Chapter. |

|

|

|

Note!

Note! Note!

Note!

Note!

Note! Note!

Note!

Note!

Note! Note!

Note!

Note!

Note! Note!

Note!