Leon Mk1

| Piston and connecting rod disassemble and assemble |

| Engine code letters AEX |

| Engine code letters AER → Anchor |

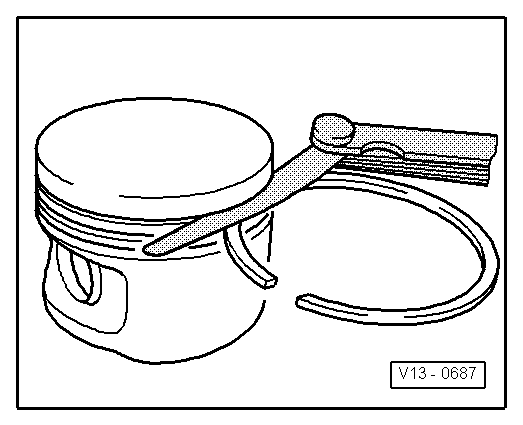

| 1 - | Piston rings |

| q | Push in 120° |

| q | Disassemble and assemble with pliers for piston rings |

| q | Manually disassemble and assemble with great care the lubrication rings made up of three parts |

| q | Mark “TOP” at the bottom of the piston |

| q | Check the impact play → Fig. |

| q | Check the height play → Fig. |

| 2 - | Piston |

| q | Check → Fig. |

| q | Mark the assembly position and the belonging to the cylinder |

| q | The arrow at the bottom of the piston indicates the side of the pulley |

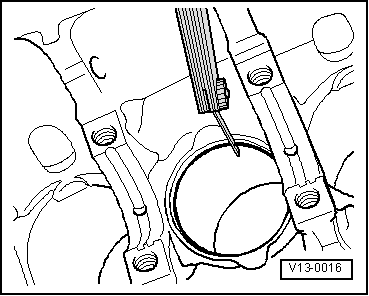

| q | Assemble with the tensing strap for the piston ring |

| 3 - | Piston pin |

| q | Heat the piston to 60 °C in case of hard movement |

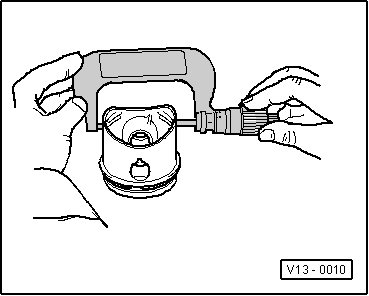

| q | Disassemble and assemble with -U-40077- |

| 4 - | Safety ring |

| 5 - | Connecting rod |

| q | Only replace by batches |

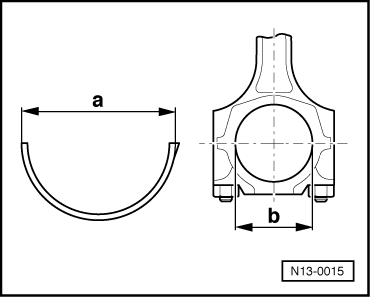

| q | Mark the belonging to the cylinder -A- |

| q | Assembly position: The -B- marks indicate the pulley |

| q | Axial guide for the piston |

| 6 - | Bearing casing |

| q | Insert the bearing casing and centre it |

| q | Do not confuse the bearing casings that were in use |

| q | Measure the initial tension → Fig. |

| q | Measure the radial play with plastigage: New: 0.020...0.061 mm Wear limit: 0.091 mm Do not turn the crankshaft when the radial play is measured |

| 7 - | Cylinder block |

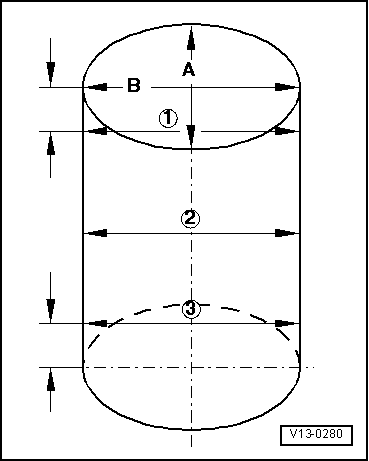

| q | Check the cylinder hole → Fig. |

| q | Piston an cylinder dimensions → Chapter |

| 8 - | Connecting rod cover |

| q | Remember the assembly position |

| q | If the connecting rods are fractured (cracked), the cover only fits in one position and only on the corresponding connecting rod |

| 9 - | Connecting rod bolt M8: 30 Nm + turn 1/4 (90°) rotation more M7: 20 Nm + turn 1/4 (90°) rotation more |

| q | Replace |

| q | Lubricate the thread and the surface |

| q | To measure the radial play, tighten with 20 or 30 Nm, but without continuing to turn |

|

| 1 - | Safety ring |

| 2 - | Piston pin |

| q | Heat the piston to 60 °C in case of hard movement |

| q | Disassemble and assemble with -U-40077- |

| 3 - | Piston |

| q | Check → Fig. |

| q | Mark the assembly position and the belonging to the cylinder |

| q | The arrow at the bottom of the piston indicates the side of the pulley |

| q | Assemble with the tensing strap for the piston ring |

| 4 - | Piston rings |

| q | Push in 120° |

| q | Disassemble and assemble the compression rings with the piston ring pliers |

| q | Manually disassemble and assemble with great care the lubrication rings made up of three parts |

| t | Mark “TOP” at the bottom of the piston |

| t | Check the impact play → Fig. |

| t | Check the height play → Fig. |

| 5 - | Connecting rod |

| q | Only replace by batches |

| q | Mark the belonging to the cylinder -A- |

| q | Assembly position: The -B- marks indicate the pulley |

| q | Axial guide for the piston |

| 6 - | Connecting rod cover |

| q | If the connecting rods are fractured (cracked), the cover only fits in one position and only on the corresponding connecting rod |

| 7 - | Connecting rod bolt, 20 Nm + turn 1/4 (90°) rotation more |

| q | Replace |

| q | Lubricate the thread and the surface |

| q | To measure the radial play, tighten with 20 Nm , but without continuing to turn |

| 8 - | Cylinder block |

| q | Check the cylinder hole → Fig. |

| q | Piston an cylinder dimensions → Chapter |

| 9 - | Bearing casing |

| q | Do not confuse the bearing casings that were in use |

| q | Measure the initial tension → Fig. |

| q | Insert the bearing casing and centre it |

| q | Measure the radial play with plastigage: New: 0.020...0.061 mm Wear limit: 0.091 mm Do not turn the crankshaft when the radial play is measured |

|

|

| Piston ring | Wear limit |

| Compression rings | 1.0 mm |

| Lubrication ring consisting of one part consisting of three parts | 1.0 mm -- → Note |

|

|

|

| Piston ring | Wear limit |

| Compression rings | 0.15 mm |

| Lubrication ring consisting of one part | 0.15 mm |

| Consisting of three parts | not measurable |

Note!

Note!

|

|

|

|