| –

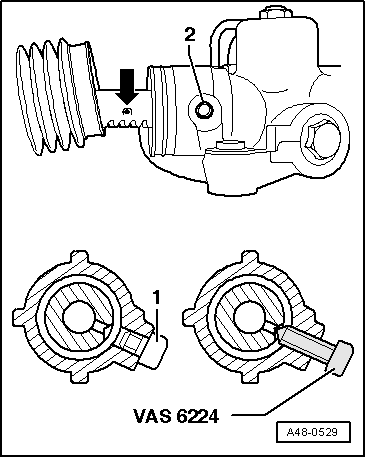

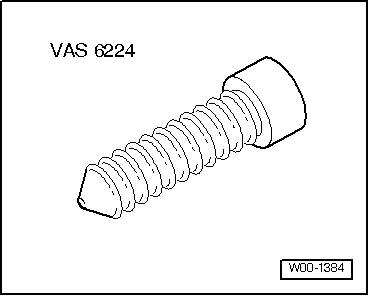

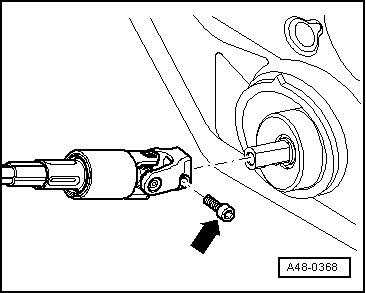

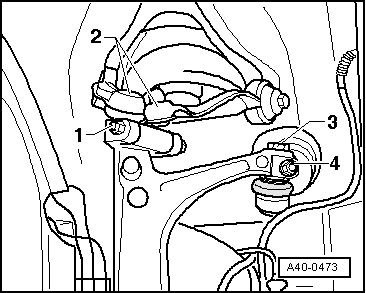

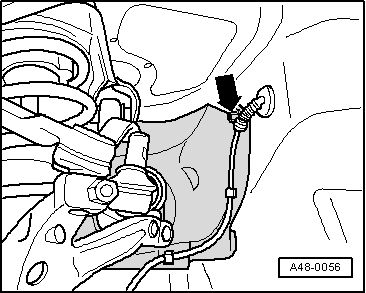

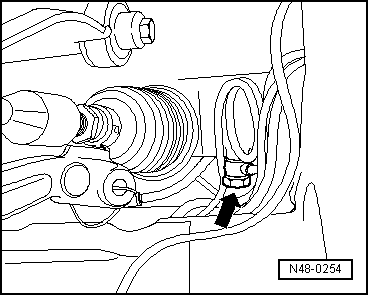

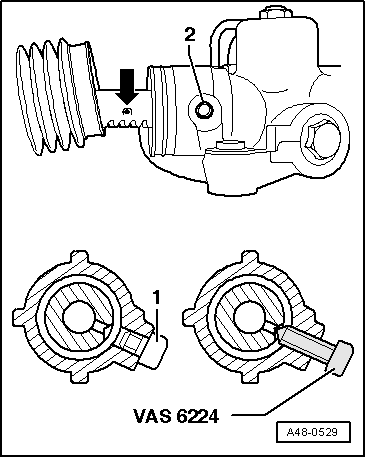

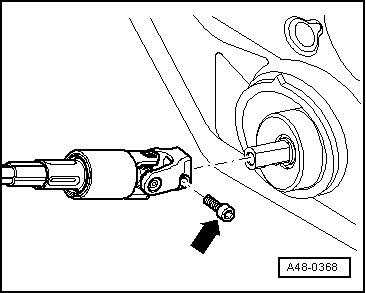

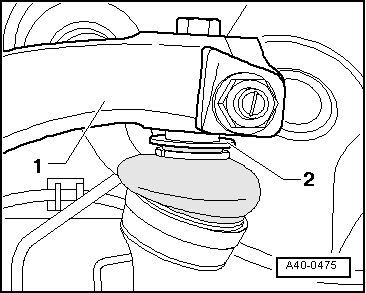

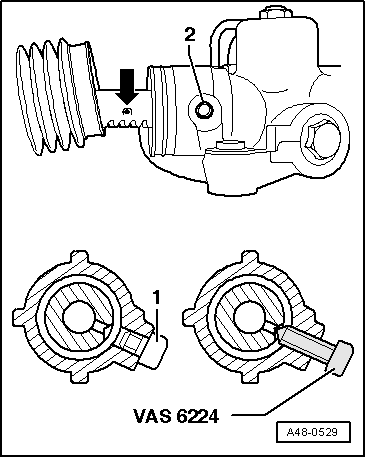

| Now unscrew steering centring bolt -VAS 6224- from steering box. |

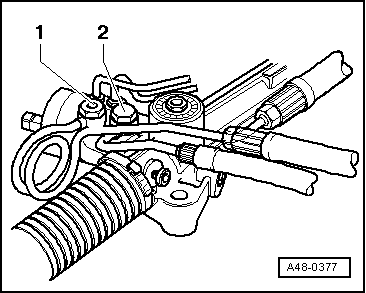

| 1 - | Hexagon socket head bolt |

| 2 - | Threaded hole in steering box |

| –

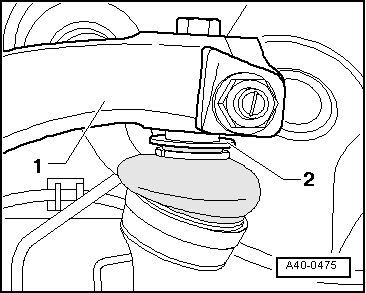

| Seal off steering box with hexagon socket head bolt -1- → Fig.. |

| –

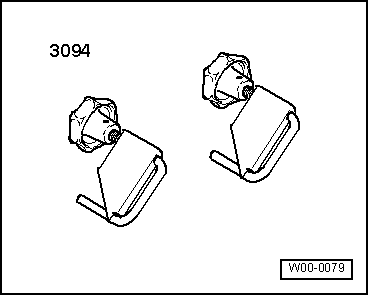

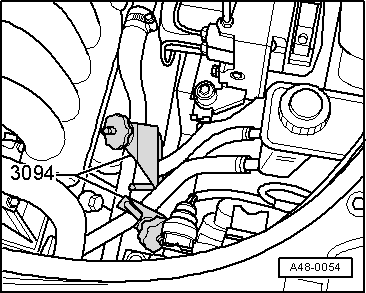

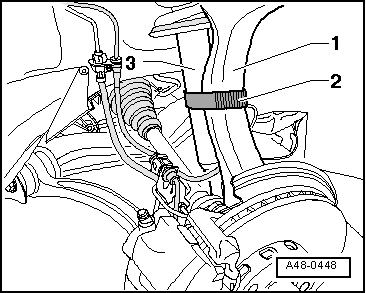

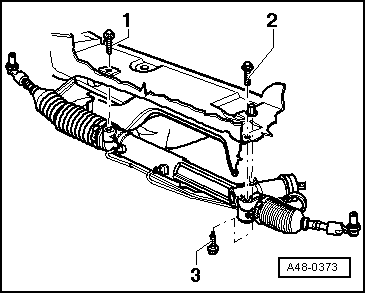

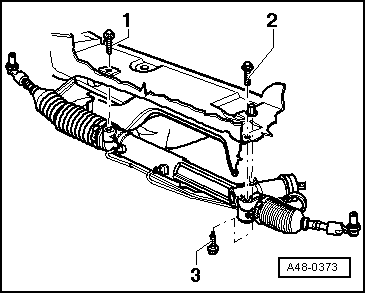

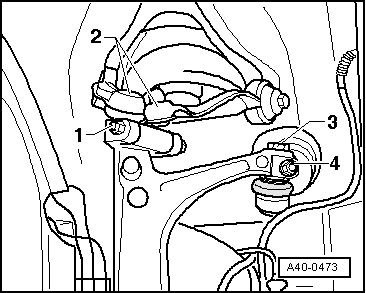

| After the complete assembly of the steering box, remove the hose clamps -3094- again. |

| –

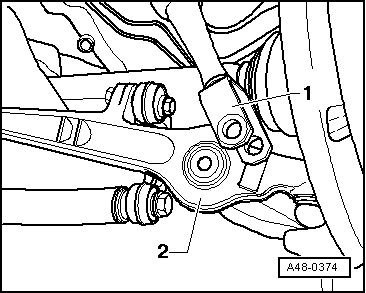

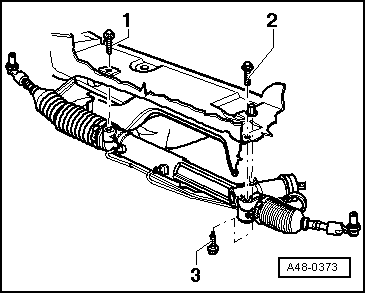

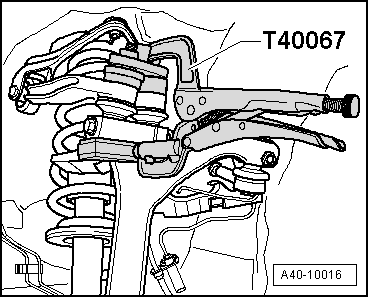

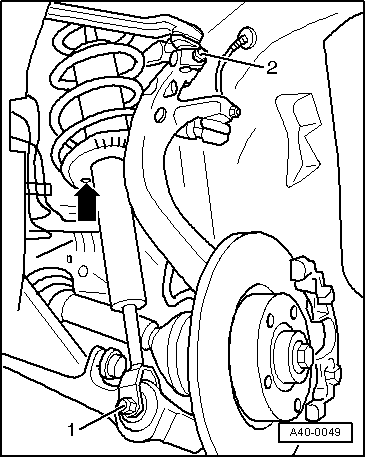

| Tighten the bolt connection of the coil spring, bumper and mounting bracket /track control link as a unit in the specified tightening torque → Item |

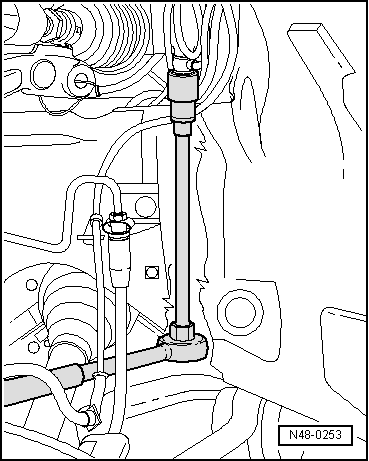

| Setting of the running gear must be done with an alignment stand recommended by SEAT. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

WARNING

WARNING