Leon Mk1

| Assembly overview - rear axle beam, front-wheel drive |

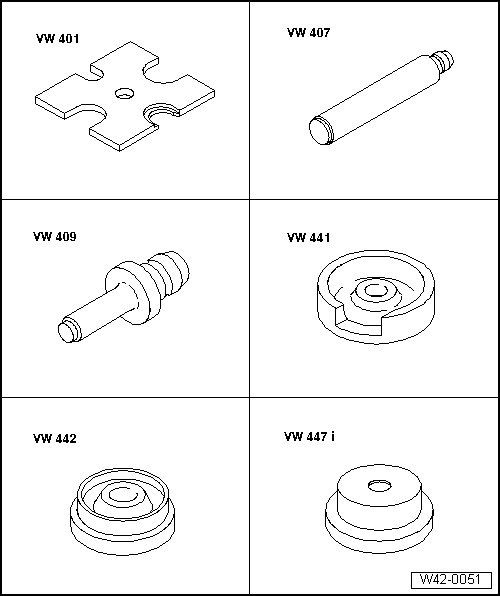

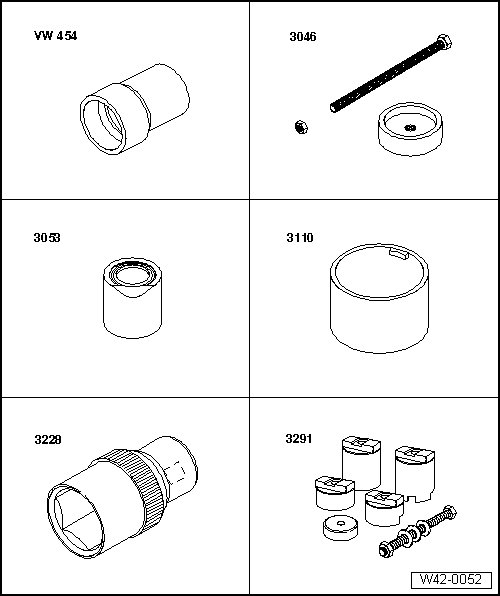

| Special tools and workshop equipment required |

| t | Press plate -VW 401- |

| t | Press tool -VW 407- |

| t | Press tool -VW 409- |

| t | Thrust piece -VW 441- |

| t | Thrust piece -VW 442- |

| t | Thrust plate -VW 447 i- |

| t | Thrust piece -VW 454- |

| t | Fitting tool -3046- |

| t | Guide sleeve -3053- |

| t | Tube -3110- |

| t | Socket insert 41 mm -3228- |

| t | Assembly tool -3291- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

| t | Torque wrench -V.A.G 1576- |

Note

Note| t | Welding and straightening on wheel locating/supports is not permissible. |

| t | Always renew self-locking nuts. |

| 1 - | Wheel bolt |

| q | Modified wheel bolt → Chapter |

| 2 - | Wheel bolt |

| q | Modified wheel bolt → Chapter |

| 3 - | Suspension link |

| 4 - | Wheel bearings |

| q | Repairing → Chapter. |

| 5 - | Hexagon bolt |

| q | 170 Nm |

| q | Renew each time after removing. |

| 6 - | Hexagon bolt |

| q | 100 Nm |

| 7 - | Strut |

| 8 - | Bonded rubber bush |

| q | Pressing out → Fig.. |

| q | Mark installation position → Fig.. |

| q | Pressing in → Fig.. |

| 9 - | Nut |

| q | 170 Nm |

| 10 - | Threads in longitudinal member |

| If thread is damaged → Chapter. |

| 11 - | Hexagon bolt |

| q | 30 Nm |

| 12 - | Clamp |

| 13 - | Anti-roll bar |

| 14 - | Rubber bush, slotted |

| 15 - | Rubber bush |

| 16 - | Clamp |

| 17 - | Hexagon bolt |

| q | 30 Nm |

| 18 - | Hexagon bolt |

| q | Renew each time after removing. |

| 19 - | Rubber bush |

| q | Pulling out → Fig.. |

| q | Pulling in → Fig.. |

| 20 - | Coil spring |

| q | Removing: first remove upper bolt from shock absorber → Chapter. |

| q | Examine for paint damage and rectify paint damage if necessary |

| q | Allocation → Electronic Parts Catalogue “ETKA”. |

| 21 - | Upper damping ring |

| q | Turn so that the end of the spring is in the recess. |

| 22 - | Bump stop |

| q | 40 Nm |

| q | Fitting and removing → Fig.. |

| 23 - | Nut |

| q | 170 Nm |

| 24 - | Thread in cross-member |

| If the welded nut threads in the cross member are damaged, the thread can be serviced with Heli-coil thread insert. |

| This repair is only possible if the bearing bracket is secured with bolts → Item M 10 x 30. |

| 25 - | Bearing bracket |

| 26 - | Hexagon bolt |

| q | Allocation → Electronic Parts Catalogue “ETKA”. |

| q | M 10 x 25; 65 Nm |

| q | M 10 x 30; 50 Nm and turn 90° further |

| q | Renew each time after removing. |

| 27 - | Hexagon bolt |

| q | Renew each time after removing. |

| 28 - | Axle beam |

| q | Aligning axle beam to vehicle → Chapter. |

| 29 - | Hexagon bolt |

| q | 260 Nm |

| q | Renew each time after removing. |

| 30 - | Rubber bush |

| q | Pulling out → Fig.. |

| q | Pulling in → Fig.. |

| q | Camber and toe can be corrected with a rubber bush with eccentric bushing → Fig.. |

| 31 - | Hexagon bolt |

| q | 110 Nm |

| q | Renew each time after removing. |

| 32 - | Gas-filled shock absorber |

| q | Removing and installing → Chapter. |

| q | Allocation → Electronic Parts Catalogue “ETKA”. |

| 33 - | Cap |

| 34 - | Nut |

| q | 130 Nm |

| q | Renew each time after removing. |

| 35 - | Hexagon bolt |