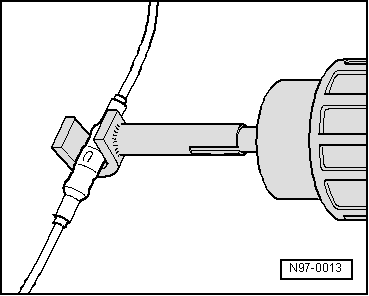

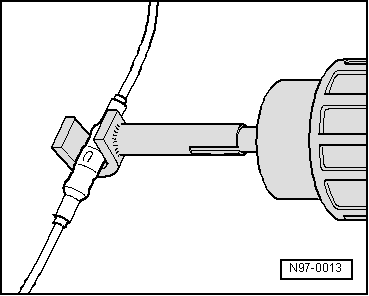

| Set the blower at the temperature shown in the Instruction Manual. |

| When heating for sealing, be careful not to damage other wiring, plastic parts or insulation with the hot nozzle of the blower. |

| –

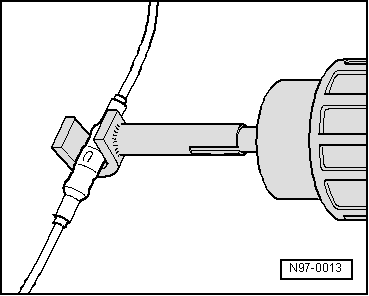

| If the repair wire was previously taped, it must be taped with yellow adhesive tape or, if necessary, fix the wire with a clamp. |

|

|

|

Note!

Note!

Note!

Note!