Leon Mk2

| Repairing trailing arm |

| Special tools and workshop equipment required |

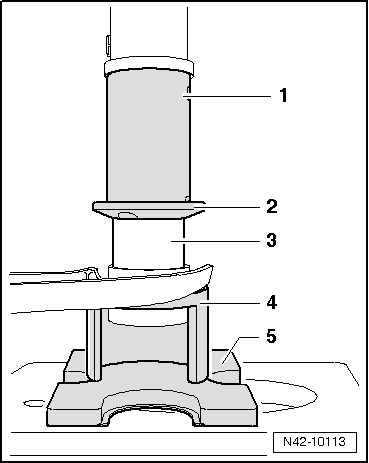

| t | Tightening plate -VW 401- |

| t | Tightening plate -VW 402- |

| t | Removal tool -3372- |

| t | attachment tool -T10230- |

|

|

|

|

|

|

|

Note

Note

|

|

|

|