| Adjusting the input shaft |

| Special tools and workshop equipment required |

| t

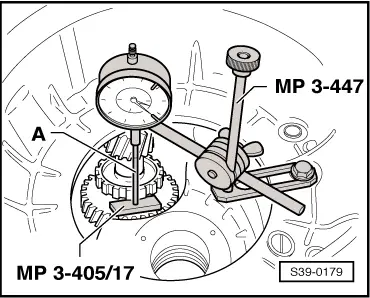

| Gauge block plate -MP 3-405/17- |

| t

| Universal dial gauge holder -MP 3-447- |

| t

| Thrust piece -MP 3-423- |

| t

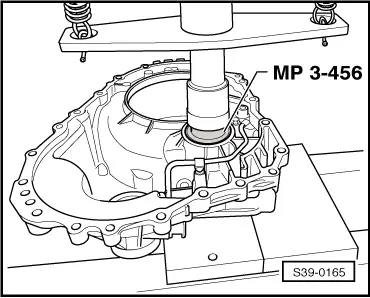

| Pressure washer -MP 3-456- |

| t

| Dial gauge extension -T30025/5- |

| t

| Torque wrench (5...50 Nm), e.g. -V.A.G 1331- |

| The input shaft must be reset if |

| t

| Torque converter housing |

| t

| Tapered-roller bearing of the input shaft |

| Necessary adjusting work when replacing individual components → Chapter. |

| l

| Removing the planetary gear from the ATF pump through to the large sun gear → Chapter |

| l

| Removing oil pan and slide valve body → Chapter |

|

|

|

Note

Note