Fabia Mk1

Note

Note

|

|

|

|

Note

Note

|

|

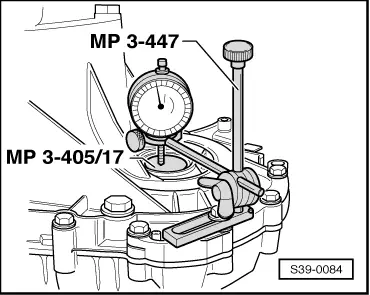

| measured value | 2,30 mm |

| + pressure (const. value) Value) | 0,20 mm |

| Thickness of the adjusting washer = | 2,50 mm |

|

|

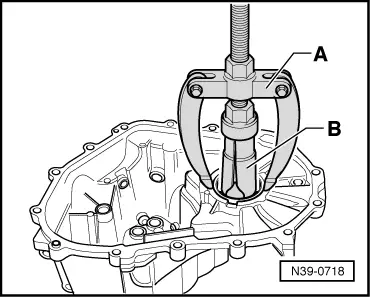

| Thickness (mm) | Spare part No. |

| 2,0 | 002 409 383 A |

| 2,1 | 002 409 383 B |

| 2,2 | 002 409 383 C |

| 2,3 | 002 409 383 D |

| 2,4 | 002 409 383 E |

| 2,5 | 002 409 383 F |

| 2,6 | 002 409 383 G |

| 2,7 | 002 409 383 |

|