Fabia Mk1

|

Note

Note| t | Replace the clutch discs and pressure plates if the riveting is damaged or loose. |

| t | Assign the clutch disc and pressure plate via the → Electronic catalogue of original parts and in accordance with the engine identification characters. |

| t | Check whether the dowel sleeves for centering the engine/gearbox are present in the cylinder block; insert if necessary. |

| t | If the dowel sleeves are not installed, this can result in problems with the gearshift and the clutch or the gearbox can be loud. |

| 1 - | Flywheel |

| q | make sure the centering pins are tight |

| q | The locating face for the clutch lining must be free from grooves, oil and grease |

| q | Removing and Installing → Engine; Rep. Gr.13 |

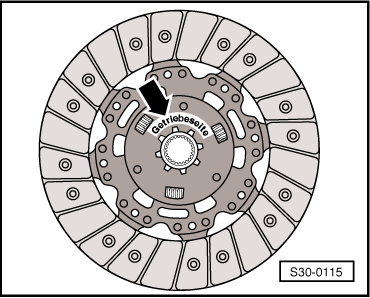

| 2 - | Clutch disc |

| q | Diameter → Chapter |

| q | Fitting position for simple flywheel: the spring cage pointing towards the pressure plate |

| q | Fitting position for two-mass flywheel → Fig. |

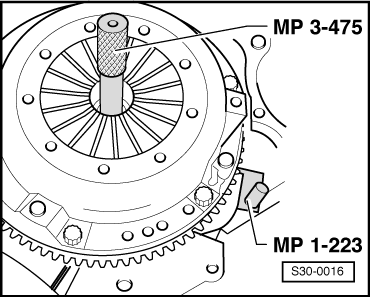

| q | center → Fig. |

| q | slightly grease the serration |

Note

Note| t | Clean the drive shaft serration and hub serration on used clutch discs, remove corrosion. Only apply a very thin layer of grease -G 000 100- onto the serration of the drive shaft. |

| t | Subsequently move the clutch disc up and down on the drive shaft until the hub fits smoothly on the shaft. |

| t | Remove all excess grease. |

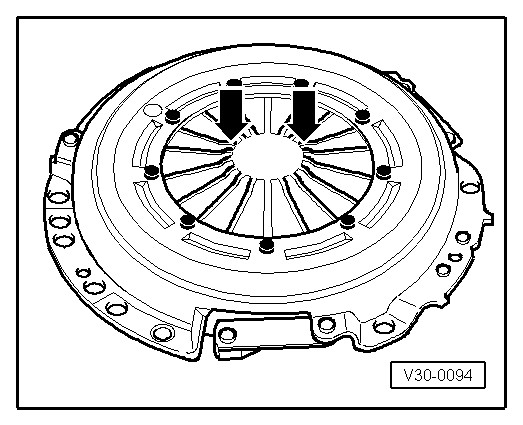

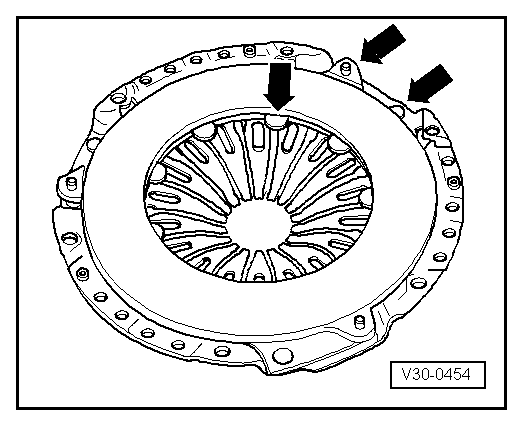

| 3 - | Pressure plate |

| q | removing and installing → Fig. |

| q | Check the extremities of the membrane spring → Fig. |

| q | Check springs and riveted joints → Fig. |

Note

Note| The pressure plates are protected against corrosion and are greased. Only clean the thrust surface as otherwise the life of the clutch may be considerably reduced. |

| 4 - | 20 Nm |

| q | assign → Electronic Catalogue of Original Parts |

| q | for two-mass flywheel with thread M6: 13 Nm |

| q | for two-mass flywheel with thread M7: 20 Nm |

| q | Release or tighten gradually and crosswise |

|

|

|

|

|

|