| –

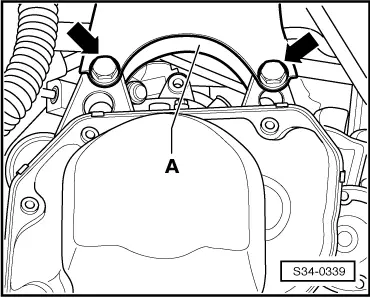

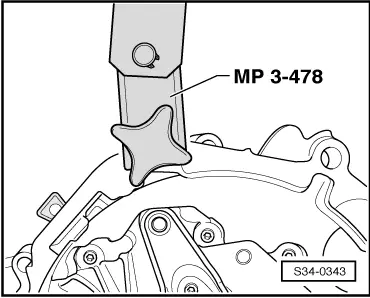

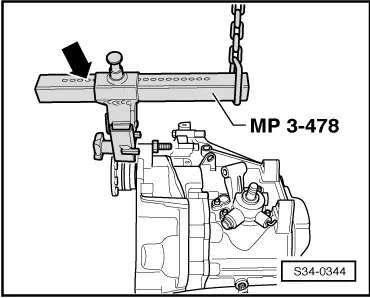

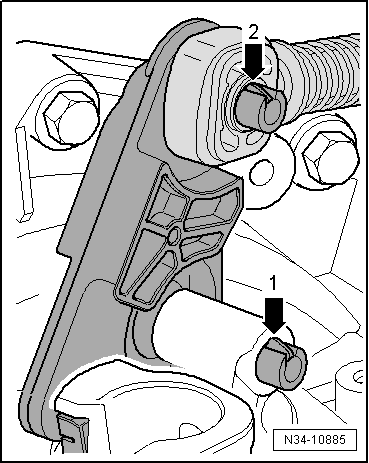

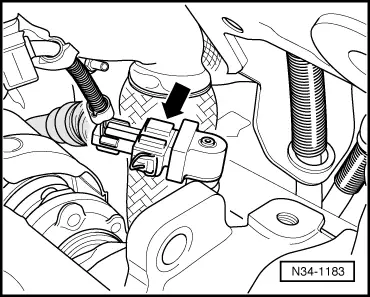

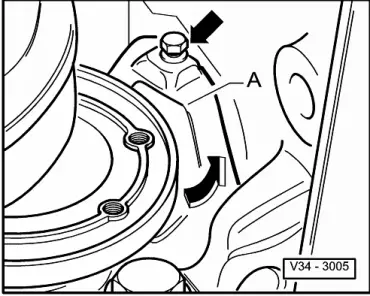

| Detach gearbox mounting bracket -A- from the gearbox. |

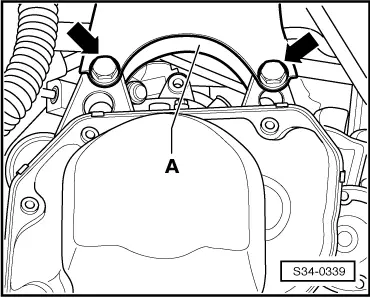

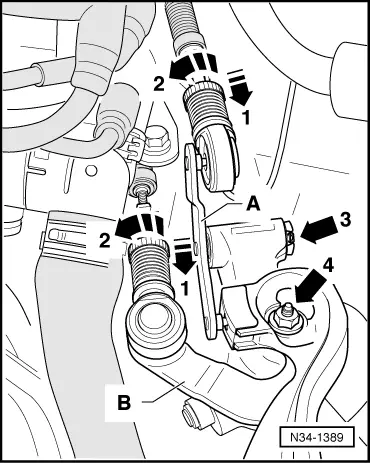

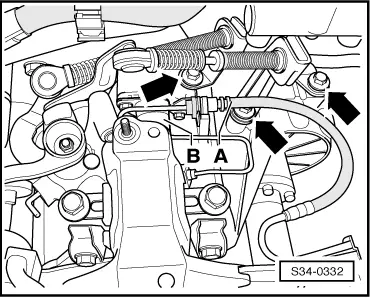

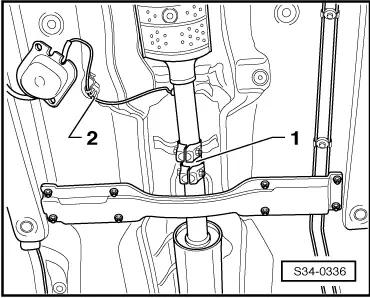

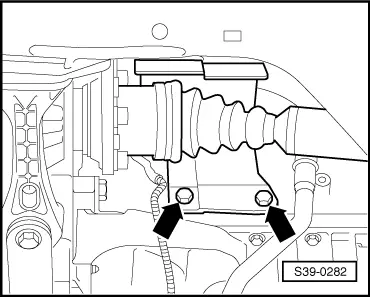

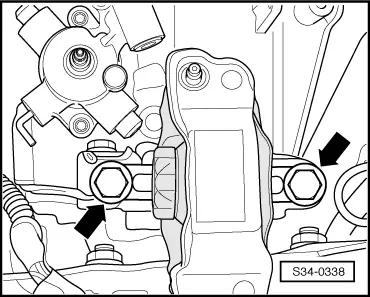

| Remove the fixing screws -arrows- for the gearbox mounting bracket as follows: |

| –

| Lower engine/gearbox unit sufficiently at the two spindles until the fixing screws attaching the gearbox mounting bracket -A- are accessible from the left wheelhouse. |

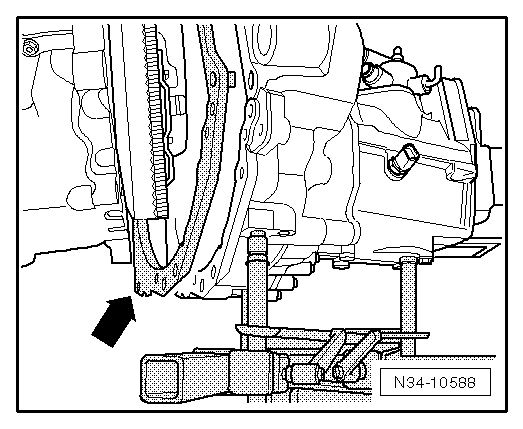

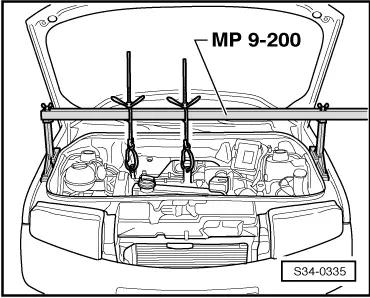

Note | When lowering the engine/gearbox unit, make sure the gearbox does not touch the assembly carrier. |

| –

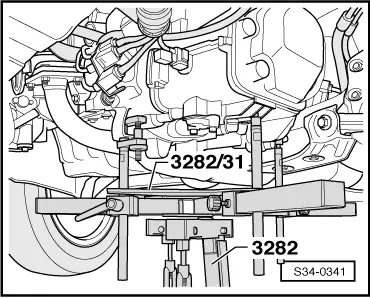

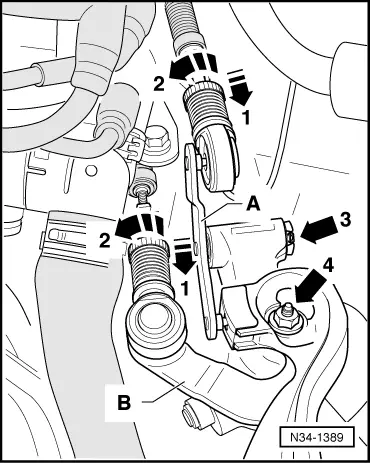

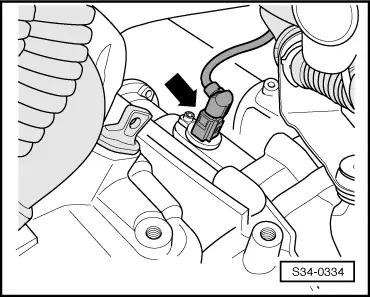

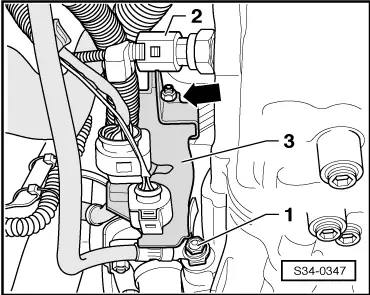

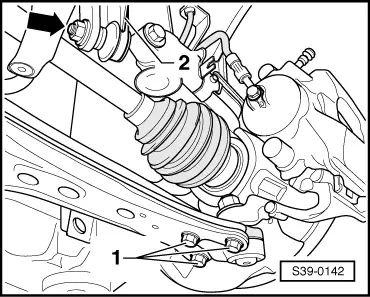

| Insert engine mount -3282- into engine and gearbox jack, (e.g.-V.A.G 1383 A -). |

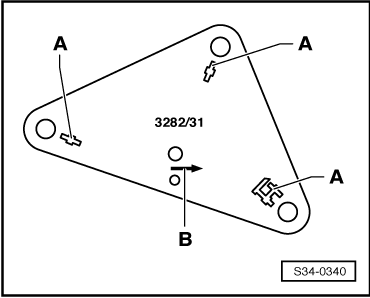

| Complete engine/gearbox jack with gearbox mount -3282-, adjusting plate -3282/31- for gearbox “02T” and support elements as follows: |

| –

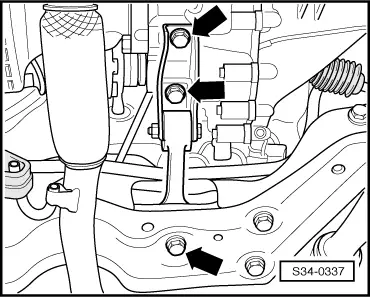

| Position adjusting plate -3282/31- on gearbox mount -3282- (adjusting plate fits in only one position). |

| –

| Align arms of the gearbox mount to match the holes in the adjusting plate. |

|

|

|

Note

Note

Note

Note

Note

Note