Fabia Mk1

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

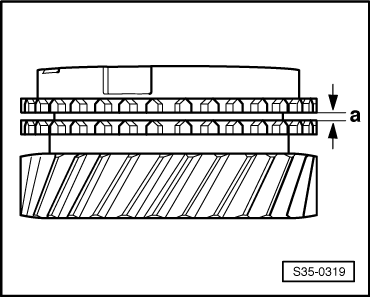

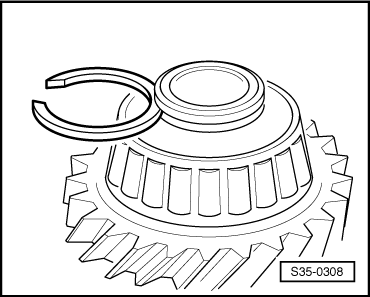

| Clearance -a- | Fitting dimension | Wear limit |

| 5th and 6th gear | 1.0 ... 1.7 mm | 0.5 mm |

|

|

|

|

|

|

|

|

|

|

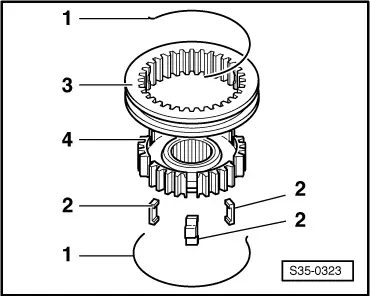

| Thickness (mm) | Spare part No. |

| 1,79 | 02M 311 187 G |

| 1,83 | 02M 311 187 F |

| 1,86 | 02M 311 187 E |

| 1,89 | 02M 311 187 D |

| 1,92 | 02M 311 187 C |

| 1,95 | 02M 311 187 B |

| 1,98 | 02M 311 187 A |

|

|

|

|

|

|

Note

Note