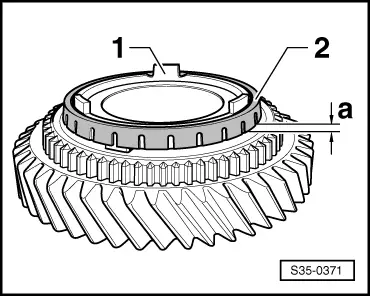

| Check the outer friction surface of the intermediate ring for wear |

| –

| Check synchronizer ring -arrow- on the inner friction surface (position to intermediate ring) for scoring and radial bearing marks, replace if necessary. |

| –

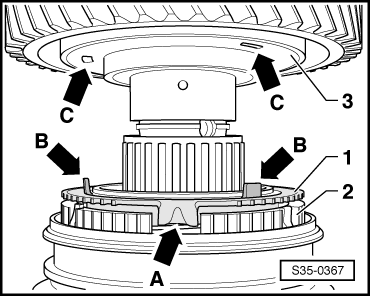

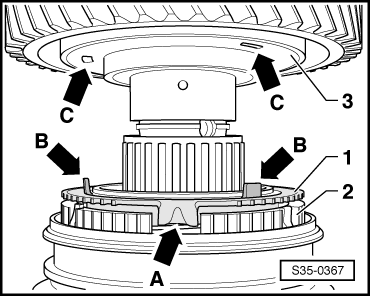

| Position inner ring, intermediate ring and synchronizer ring in fitting position → Fig. onto the sliding gear and “screw in”. |

Note | “Screw in ” means: Turn synchronizer rings by one revolution while pressing on the rings simultaneously. |

| –

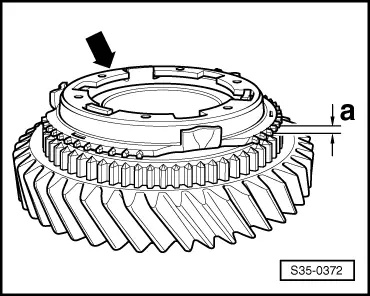

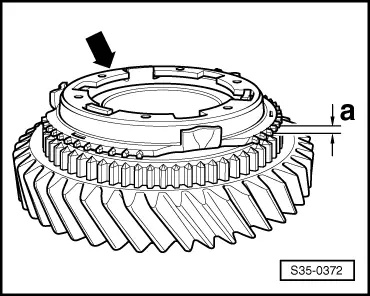

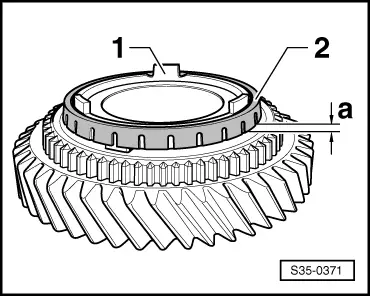

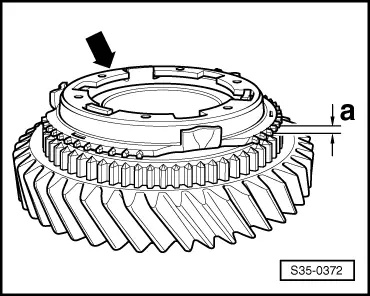

| Then measure the gap -a- at 3 points, offset by 120°, with a feeler gauge. Note the mean value. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note