| –

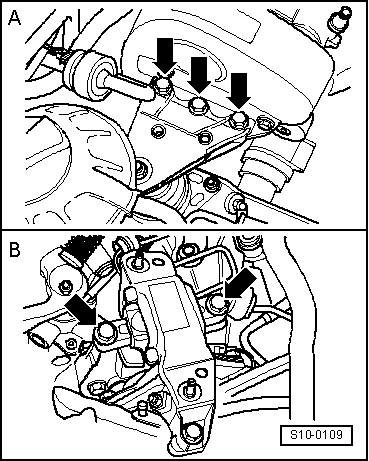

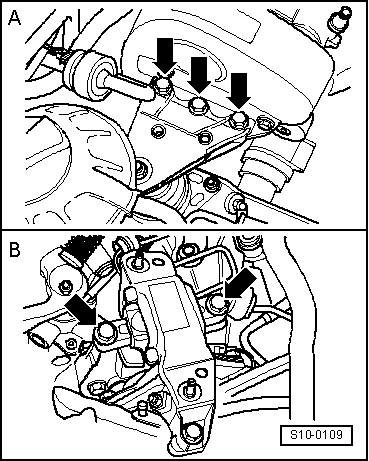

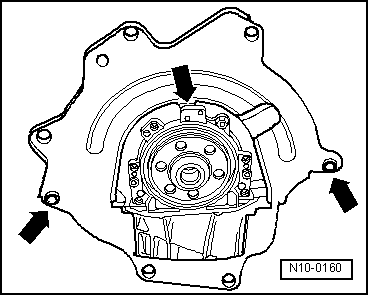

| Secure unit in the engine and gearbox mount -arrows- and tighten the screws to the recommended tightening torque → Chapter. |

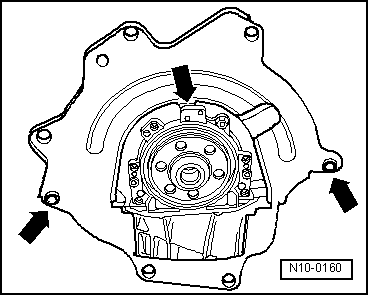

| Vehicles fitted with a manual gearbox |

| Continued for all vehicles |

| Vehicles with air conditioning |

Note | To avoid damaging the condenser, wiring and coolant hoses, make sure the lines and hoses are not excessively expanded, buckled or bent. |

| Continued for all vehicles |

| –

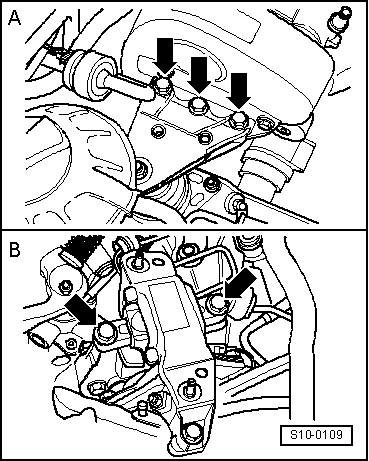

| Install pendulum support and tighten the screws to the prescribed tightening torque → Chapter. |

| –

| Install pre-exhaust pipe: |

| t

| Engines with identification characters AUA, AUB, BBY, BBZ → Chapter |

| t

| Engine with identification characters BKY → Chapter |

| t

| Engine with identification characters BUD → Chapter |

| For engines with identification characters AUA, AUB, BBY, BBZ, BKY |

| –

| Install engine cover with air filter. |

| For engine with identification characters BUD |

| For engines with identification characters BKY up to 05/2005, AUA, AUB, BBY, BBZ |

| Continued for all vehicles |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note