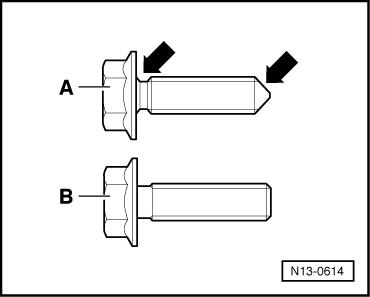

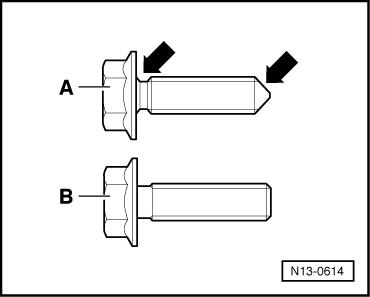

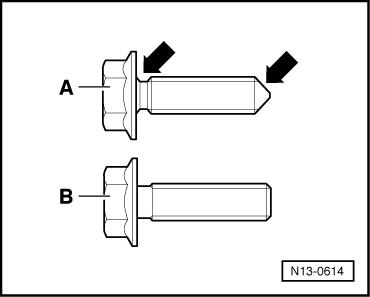

| Version -A-: fixing screws with relief under the head and tip -arrows- |

| –

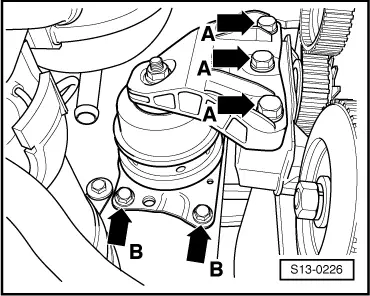

| Tighten the new fixing bolts of the injection pump gear. |

Note | t

| After a dynamic test of the start of pump delivery tighten the fixing bolts to the torquing angle by 90° (1/4 turn). |

| t

| The fixing bolts must be used once only as they are antifatigue bolts. |

| Version -B-: fixing screws without relief under the head and without tip |

| –

| Tighten the old fixing bolts of the injection pump gear. |

Note | Do not replace the fixing bolts. |

| Continued for all versions: |

| –

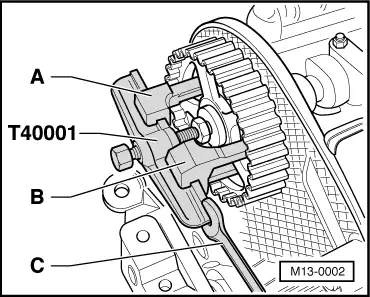

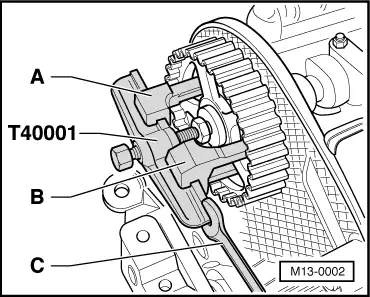

| Remove the camshaft straightedge -MP1-312- from the camshaft. |

| –

| Pull out the rig pin -MP1-301-. |

| –

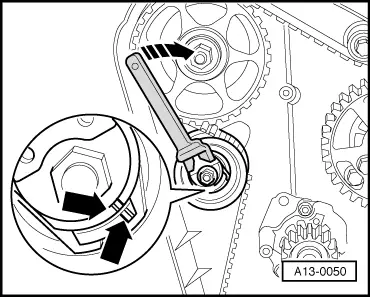

| Turn crankshaft two turns further in the direction of running of the engine and again position on TDC for cylinder 1. |

| t

| the TDC marking on the flywheel is aligned, |

| t

| the camshaft straightedge can be inserted in the camshaft, |

| t

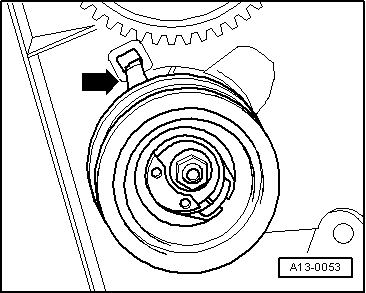

| the rig pin is inserted in the injection pump gear, |

| t

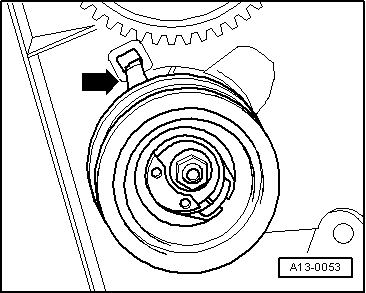

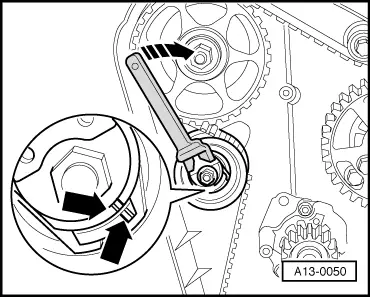

| the setting of the tensioning pulley (notch/lobe) is aligned. |

| –

| If the notch and the lobe are not opposite one another, tighten the tensioning pulley and the fixing nut to 25 Nm. |

| –

| Turn crankshaft two turns further in the direction of running of the engine until the crankshaft is again on TDC for cylinder 1. |

| –

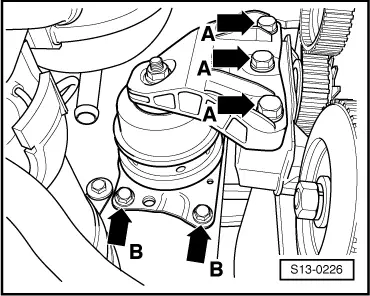

| Fit engine support bracket on the cylinder block. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note Note

Note

Note

Note