| –

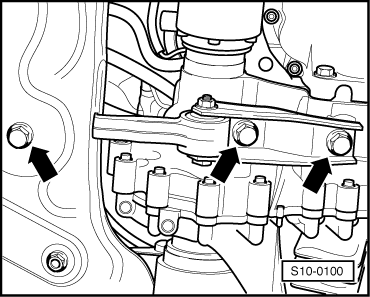

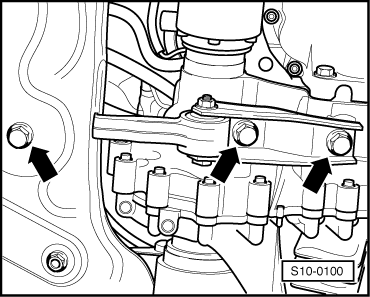

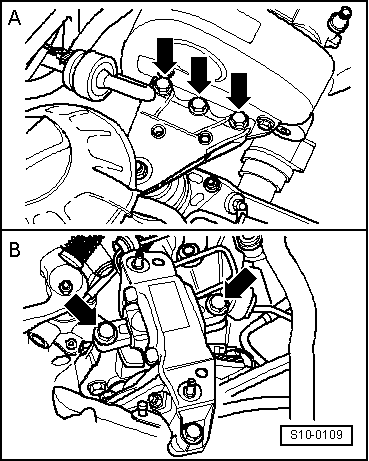

| Remove pendulum support -arrows-. |

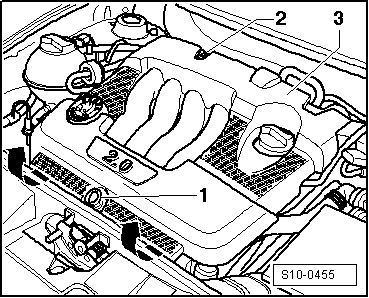

| Vehicles with air conditioning |

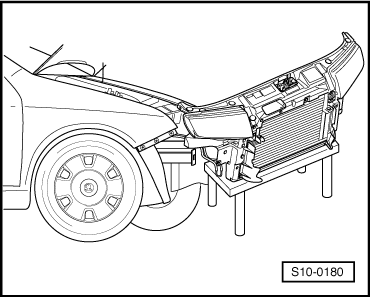

WARNING | Do not open the refrigerant circuit of the air conditioning system. Therefore, when laying aside the lock carrier pay special attention to the air conditioning hoses, that must not be folded or exposed to stress. |

|

Note | To avoid damaging the condenser, wiring and coolant hoses, make sure the lines and hoses are not excessively expanded, buckled or bent. |

Note | Observe supplementary instructions and assembly work → Chapter. |

| –

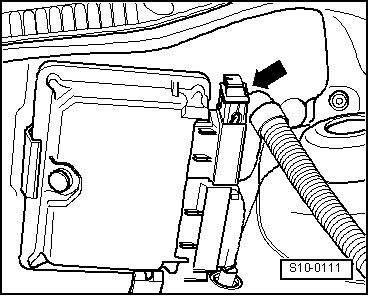

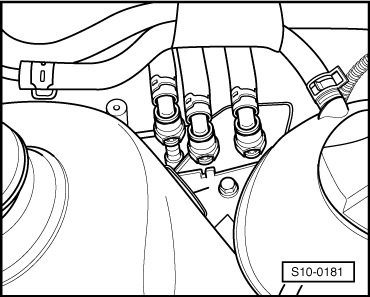

| Unscrew the retaining clips of the air conditioning lines. |

| –

| Remove connector from the AC compressor. |

| –

| Attach the AC compressor to the lock carrier. |

| Continued for all vehicles |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note Note

Note

Note

Note Note

Note

Note

Note

Note

Note

WARNING

WARNING