| –

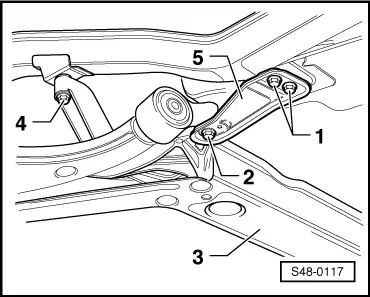

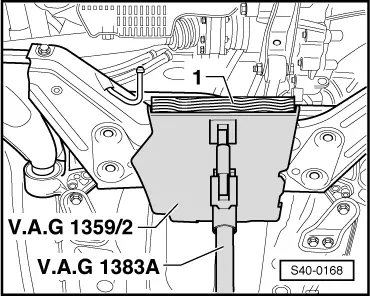

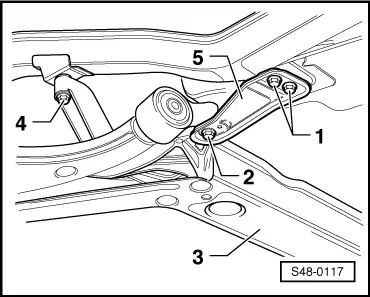

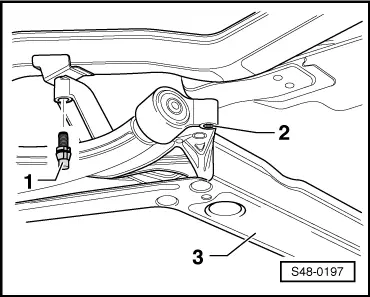

| Unscrew left screw -4- for assembly carrier -3-, screw in fixing bolt -T10096- and tighten to 20 Nm. |

| –

| Unscrew right screw -4- for assembly carrier (not shown in figure), screw in fixing bolt -T10096- and tighten to 20 Nm. |

| –

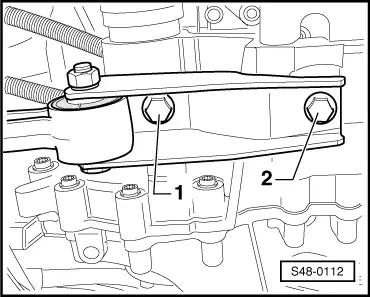

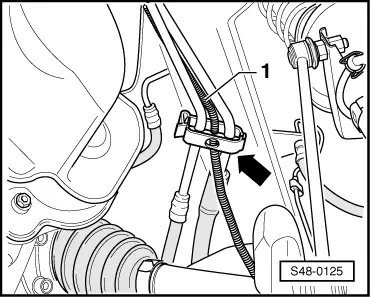

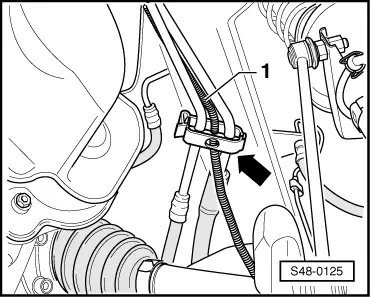

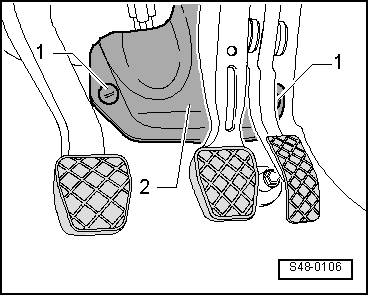

| Unscrew bolts -1- on both sides. |

| –

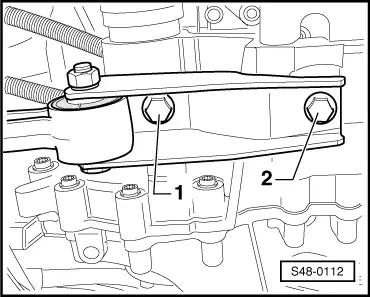

| Unscrew the left screw -2- and remove support -5-. |

| –

| Screw in fixing bolts -T10096- and tighten to 20 Nm. |

| –

| Unscrew the right screw -2- and remove support -5-. |

| –

| Screw in fixing bolts -T10096- and tighten to 20 Nm. |

| The alignment of the assembly carrier is completed once all 4 screws (Pos. -2- and -4- on both vehicle sides) are consecutively replaced with the fixing bolts. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution