Fabia Mk2

|

Note

Note| t | Before replacing the clutch disc and pressure plate fault finding power transmission - observe complaints of the clutch and clutch control → Chapter. |

| t | Replace the clutch discs and pressure plates if the riveting is damaged or loose. |

| t | Assign the clutch disc and pressure plate in accordance with engine identification characters → Electronic Catalogue of Original Parts. |

| t | In order to reduce unpleasant odours if the clutch is burnt, thoroughly clean the clutch housing as well as the flywheel and the engine on the side of the gearbox. |

| t | Clean the drive shaft serration and hub serration on used clutch discs, remove corrosion. Apply a very thin layer of grease for plug serration of clutch disc -G 000 100 - onto the serration. Subsequently move the clutch disc up and down on the drive shaft until the hub fits smoothly on the shaft. Remove all excess grease. |

| t | The pressure plates are protected against corrosion and are greased. Only clean the thrust surface as otherwise the life of the clutch may be considerably reduced. |

| t | The thrust surface of the pressure plate and the clutch disc lining must fully rest against the flywheel before the screws are installed. Only then may the fixing screws be inserted. |

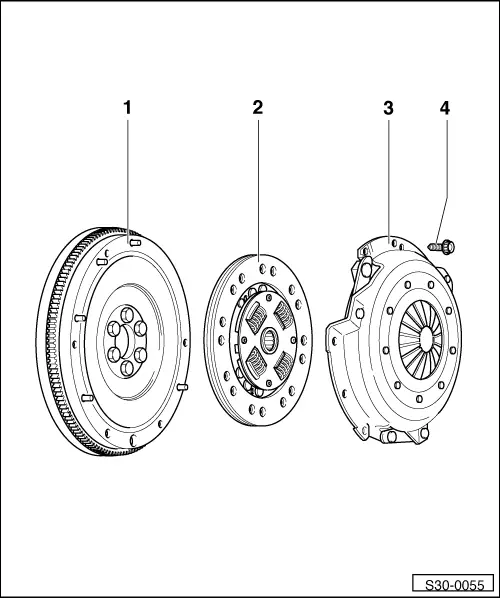

| 1 - | Flywheel |

| q | make sure the centering pins are tight |

| q | The locating face for the clutch lining must be free from grooves, oil and grease |

| q | Removing and Installing → Engine; Rep. gr.13 |

| 2 - | Clutch disc |

| q | Diameter → Electronic Catalogue of Original Parts |

| q | Fitting position for simple flywheel: the spring cage points towards the pressure plate |

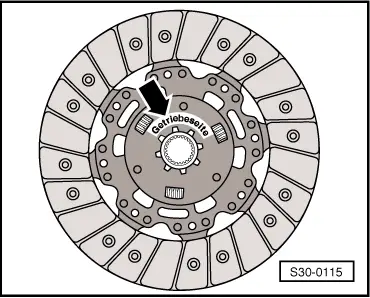

| q | Fitting position for two-mass flywheel → Fig. |

| q | center → Fig. |

| q | slightly grease the serration |

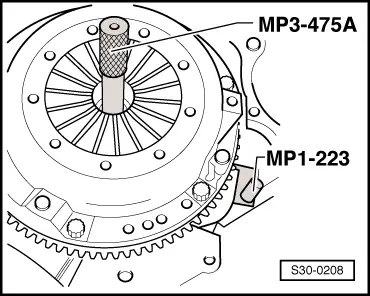

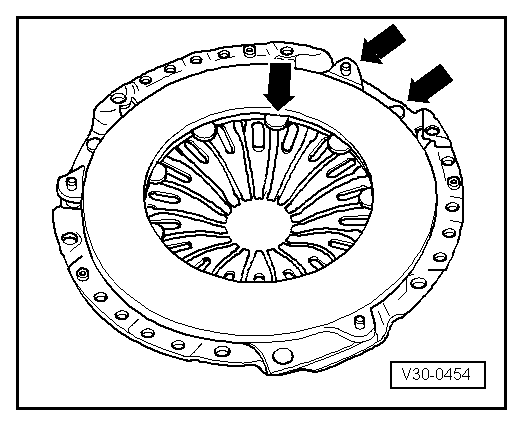

| 3 - | Pressure plate |

| q | removing and installing → Fig. |

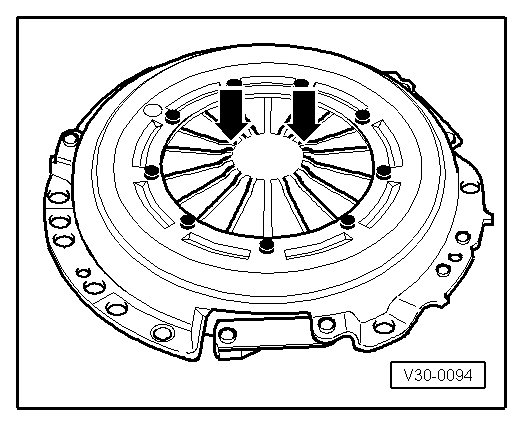

| q | Check the extremities of the membrane springs → Fig. |

| q | Check feather joints and riveted joints → Fig. |

| 4 - | Screw M6-13 Nm; screw M7-20 Nm |

| q | Assignment → Electronic Catalogue of Original Parts |

| q | Release or tighten gradually and crosswise |

|

|

|

|

|

|