| Adjusting the differential gear |

| Special tools and workshop equipment required |

| t

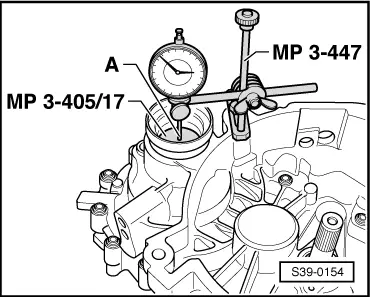

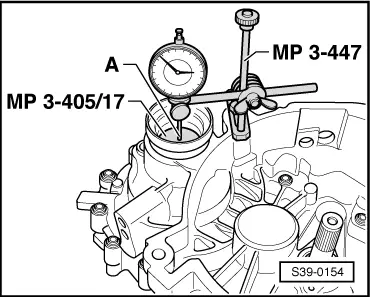

| Gauge block plate -MP3-405/17- |

| t

| Universal dial gauge holder -MP3-447 (VW 387)- |

| t

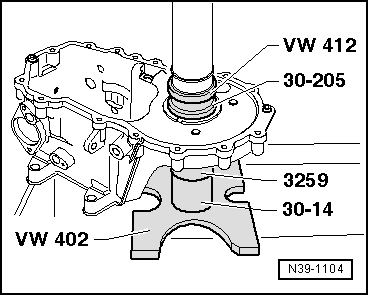

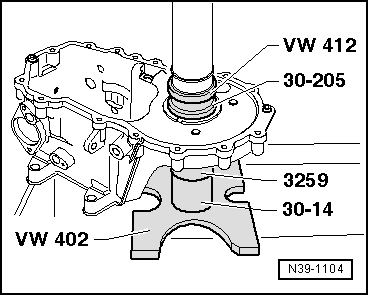

| Pressure plate -MP3-407 (VW 402)- |

| t

| Pressure plate -MP3-406 (VW 401)- |

| t

| Pressure spindle -MP3-408 (VW 412)- |

| t

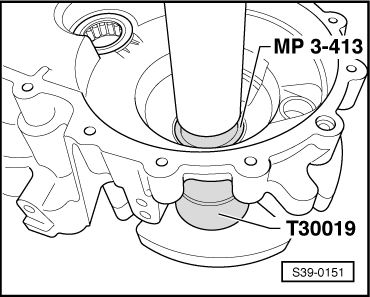

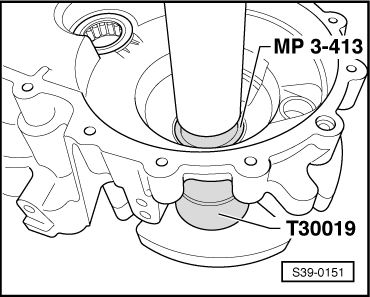

| Pressure washer -MP3-413 (VW 510)- |

| t

| Pressure pipe -MP6-408 (30-14)- |

| t

| Pipe for the wheel bearing -T30019 (3345)- |

| t

| Drive bushing -MP3-427 (40-21)- |

| t

| Interior extractor, e.g. -Kukko 21/7- |

| t

| Thrust plate -MP3-464 (30-205)- |

| The differential gear must be re-set when the following components are replaced: |

| t

| Differential gear housing |

| t

| Tapered-roller bearings of the differential gear. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note