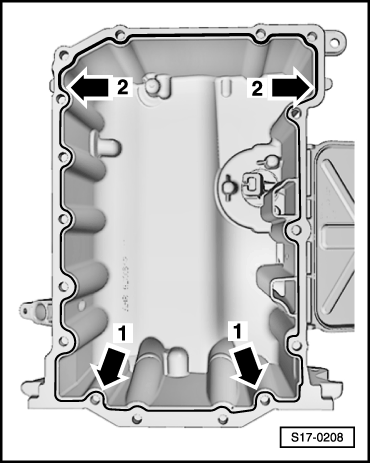

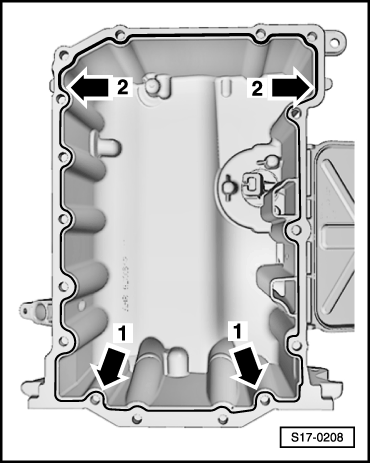

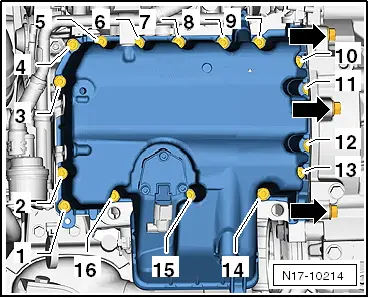

| Thickness of sealant beads on the oil pan: |

| t

| In the area of the sealing surfaces of the cylinder block and the sealing flange on the gearbox side -between arrows 1-: 2 … 3 mm |

| t

| In the area of the sealing surface of the sealing flange on the belt pulley side -between arrows 2-: 3 … 4 mm |

| l

| The old silicone seal, which is no longer present, must be replaced in the area of the sealing flange on the belt pulley side with the sealant bead equal to the height and width of the silicone seal. |

Note | After applying the sealant, install the oil pan within 5 minutes. |

Note | t

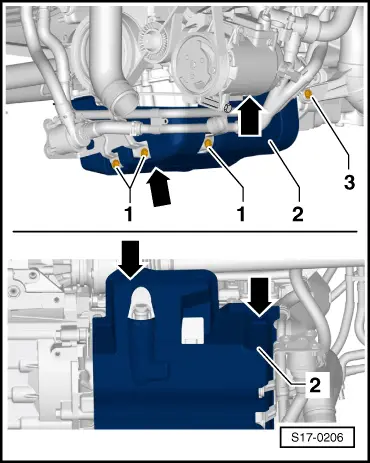

| The oil pan must be flush to the gearbox flange at the intermediate plate. |

| t

| When installing the oil pan with the engine removed, ensure that the oil pan is flush with the cylinder block at the flywheel side. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Caution

Caution WARNING

WARNING