| –

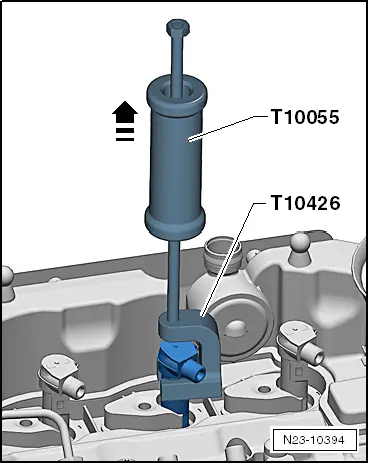

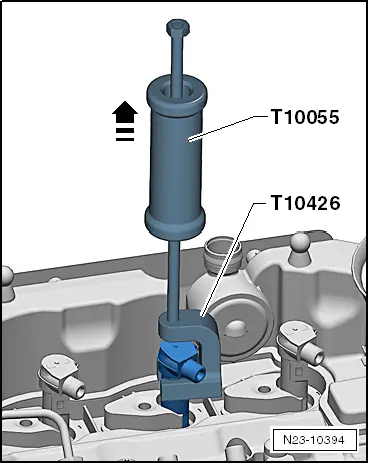

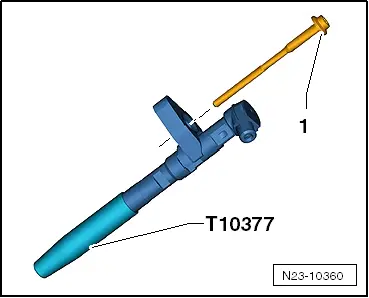

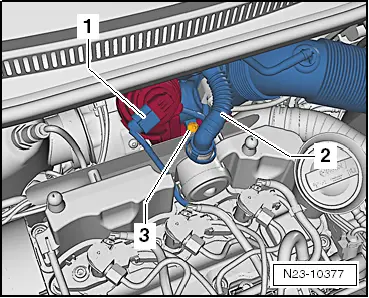

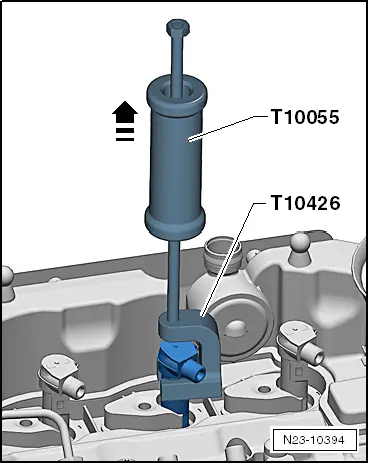

| Position the extractor -T10055- with the extractor -T10426- as shown. |

| –

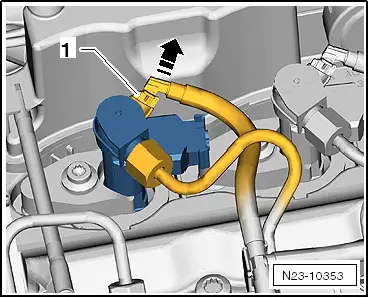

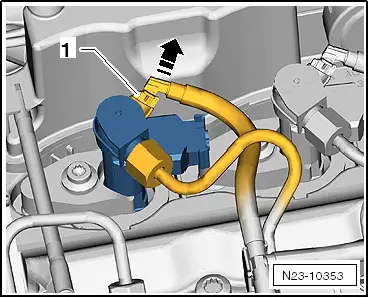

| Always pull out the injection unit together with the clamping claw towards the top by tapping it. |

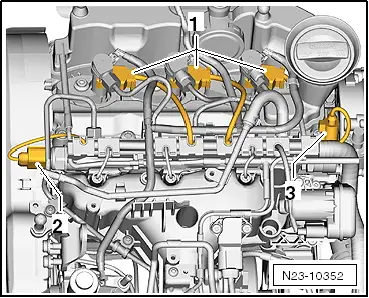

Note | Place the removed injection units on a clean cloth. |

| –

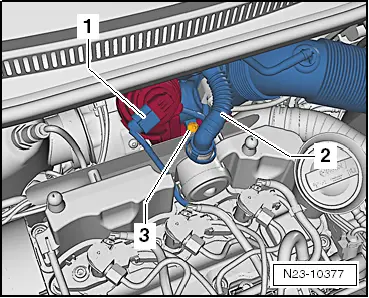

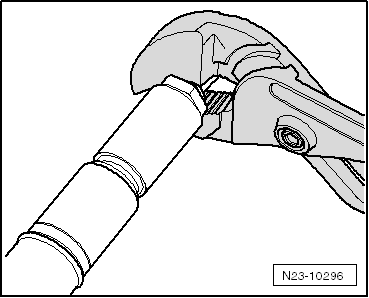

| Remove the soot particles on the sealing surface of the injection unit in the cylinder head and the dirt in the opening with a cloth soaked in engine oil or in rust solvent, if necessary. |

Caution | Make sure the sealing surfaces are not damaged in the process. |

|

| Important instructions for the replacement of parts |

| When reinstalling the injection unit, the following parts must be replaced: |

| t

| O-ring of bore for injection unit |

| t

| Screw for clamping claw |

| When installing the new injection unit, the following must also be replaced: |

| t

| Injection unit for cylinder |

| Instructions for reinstalling the injection units |

Note | t

| When reinstalling, the injection units, the injection lines and the clamping claws must only be installed at the same point where they were removed. |

| t

| The reinstalled injection units or injection lines must not be damaged. |

| –

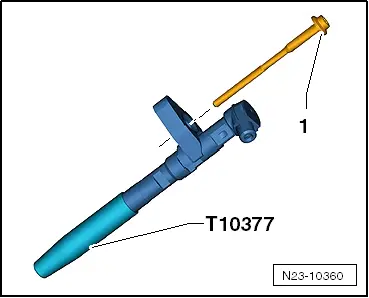

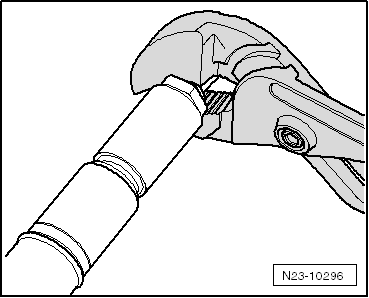

| Spray the tip of the injection unit with a rust solvent spray. Remove the soot and grease particles with a cloth after approx. 5 minutes. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note