| –

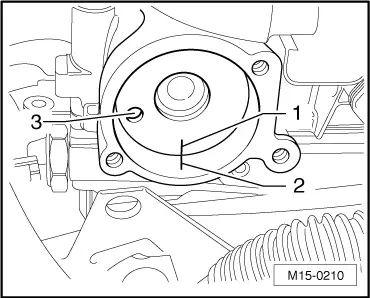

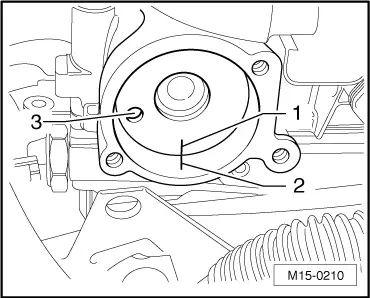

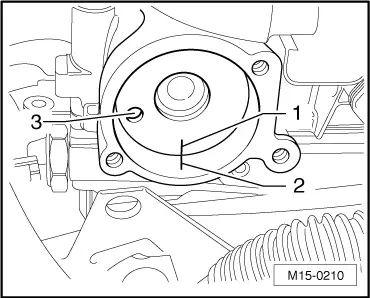

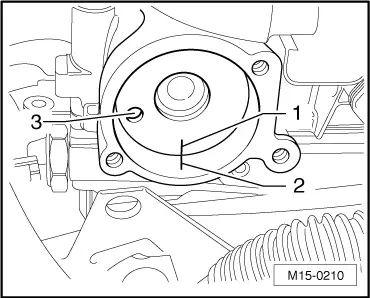

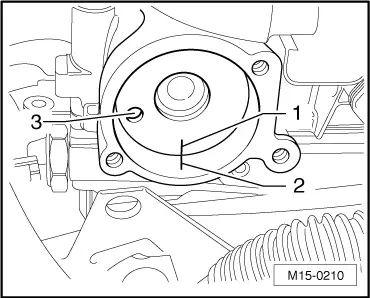

| Check the position of the outlet camshaft. |

| l

| Both markings -1- and -2- must be aligned. |

| If both markings -1- and -2- are aligned: |

|

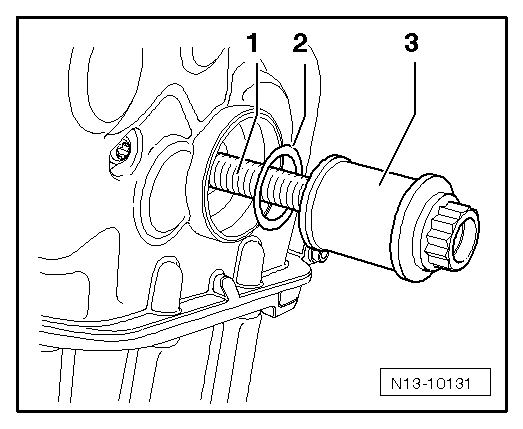

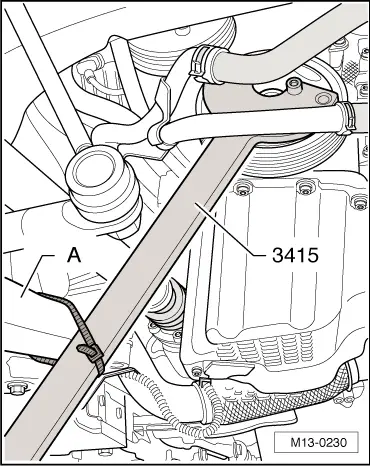

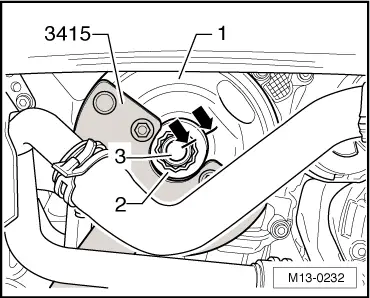

| This checks if the chain sprocket on the crankshaft has turned along when tightening the screw for the crankshaft belt pulley. |

| If both markings -1- and -2- are not aligned: |

| If the timing is not correct: |

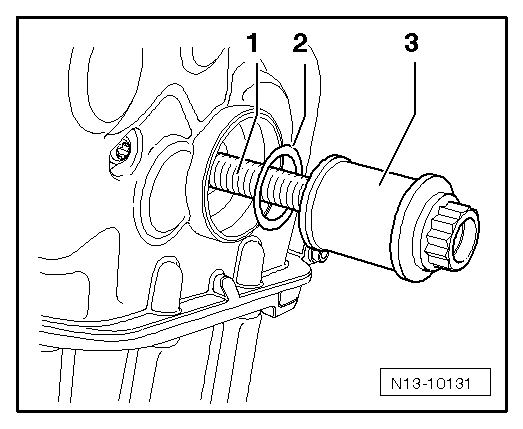

Note | First of all determine if the peg of the chain sprocket is still in the slot of the crankshaft. |

| –

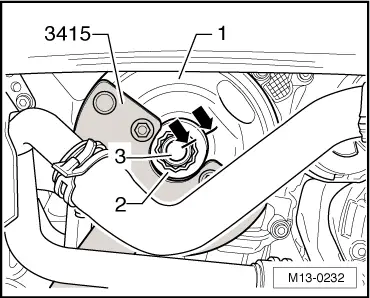

| If the peg of the chain sprocket is no longer in the slot of the crankshaft, remove the chain sprocket and inspect for damage. |

|

| Replace the damaged chain sprocket. |

| If the timing is correct: |

|

| The crankshaft has turned to the crankshaft belt pulley. |

| –

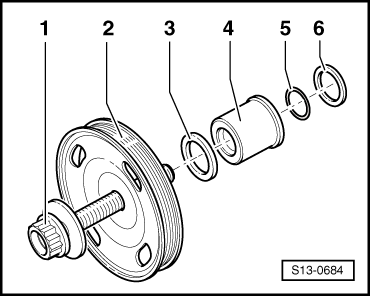

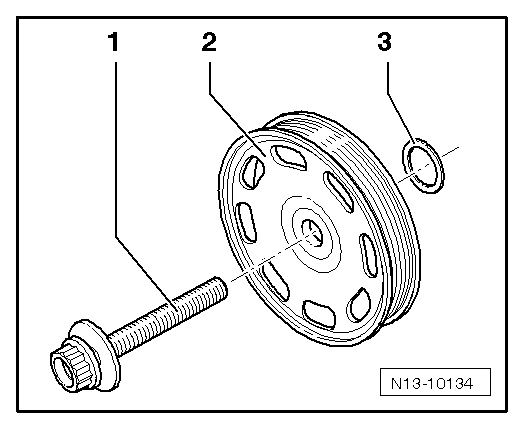

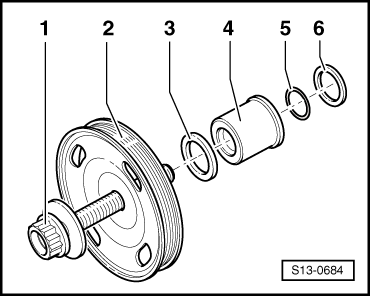

| Remove the crankshaft belt pulley, gasket ring, diamond coated washers and spacer sleeve, thoroughly clean all component parts. They must be free of oil and grease. |

| –

| Replace damaged component parts. |

| –

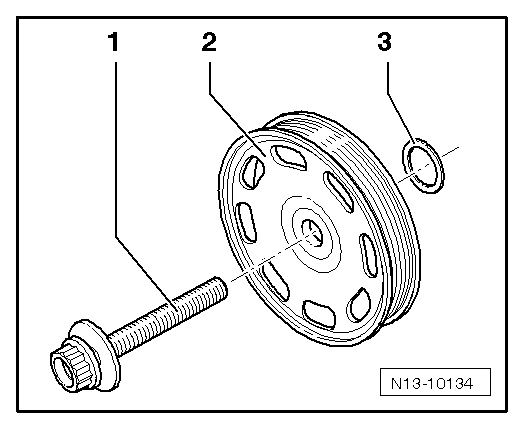

| Also throughly clean the clamping surface on the chain sprocket. |

| –

| Re-install component parts with new screw for crankshaft belt pulley. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note