| Pressing out and pressing in |

| Special tools and workshop equipment required |

| t

| Gearbox jack with adapter, e.g. -V.A.G 1383 A- with -V. A. G 1359/2- |

| t

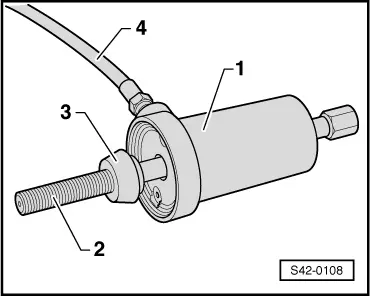

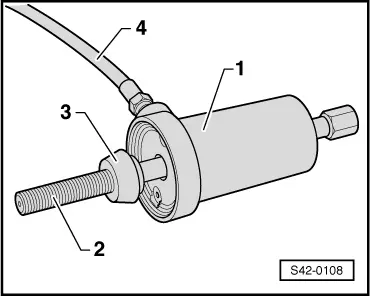

| Foot pump with high-pressure hose, e.g. -V.A.G 1389 A/1- (Paschke) |

| t

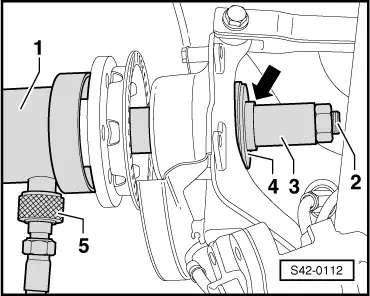

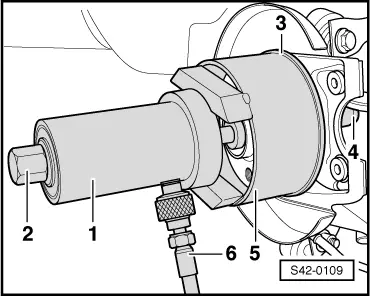

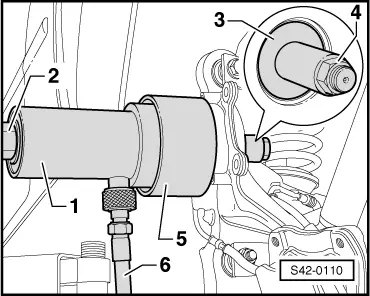

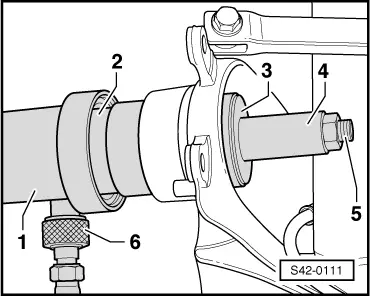

| Hydraulic removal and installation device for wheel bearing, e.g. -V.A.G 1459 B- (Paschke) |

| with the following individual tools: |

| t

| Hollow piston cylinder, e.g. -HKZ-15-, with pressure plate, e.g. -E-0-204T- |

| t

| Tie bolt, e.g. E-0-217 + 218 |

| t

| Special nut, e.g. -E-8-214- |

| t

| Pressure plate, e.g. -E-5- |

| t

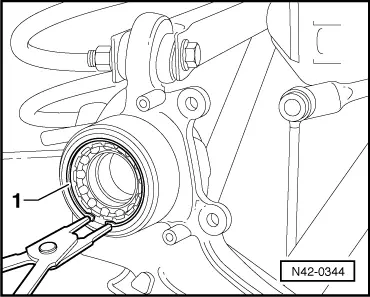

| Centering with clamp, e.g. -E-76-2- |

| t

| Supplementary kit, e.g. -V.A.G 1459 B/2- |

| with the following individual tools: |

| t

| Pressure bushing, e.g. -E-44- |

| t

| Pressure plate, e.g. -E-6-1- |

| t

| Pressure plate, e.g. -E-13-1- |

| t

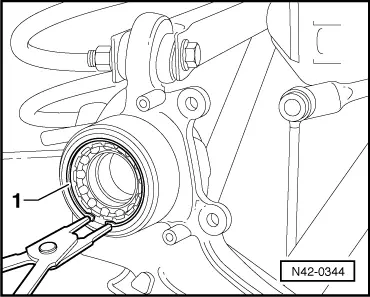

| Thrust washer, e.g. -E-39- (-VAS 5146-) |

| t

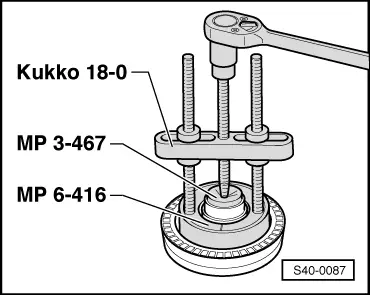

| Thrust plate -MP 3-467- |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note