Octavia Mk1

Note

Note

|

|

Note

Note

|

|

|

|

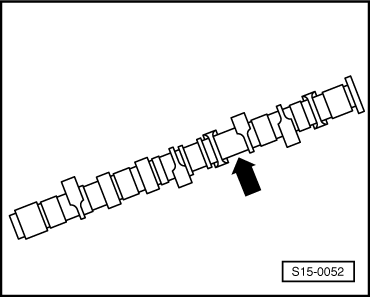

| Inlet valve opens | 7.5° after TDC |

| Inlet valve closes | 31.5° after BDC |

| Exhaust valve opens | 32.5° before BDC |

| Exhaust valve closes | 8.5°before TDC |

Note

Note

|

|

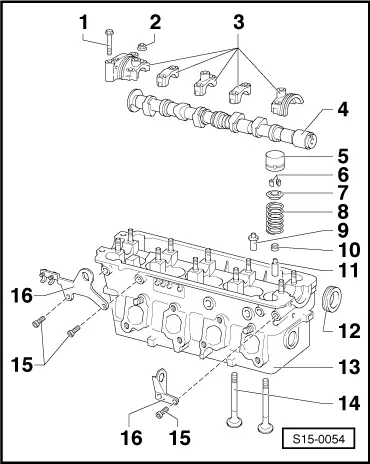

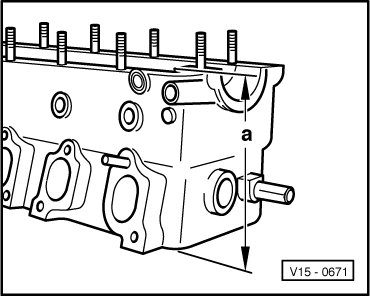

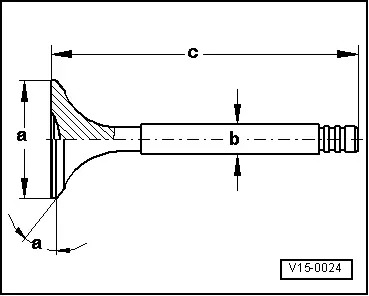

| Dimension | Inlet valve | Outlet valve | |

| Ø a | mm | 35,6 | 29,0 |

| Ø b | mm | 6,963 | 6,943 |

| c | mm | 94,8 | 95,0 |

| α | ∠° | 45 | 45 |