Octavia Mk1

Note

Note

|

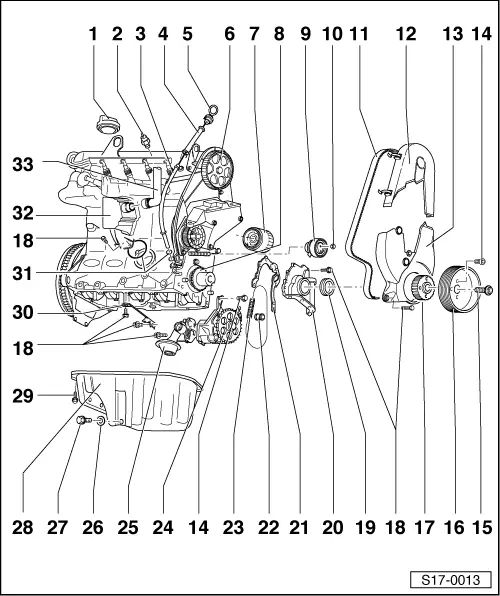

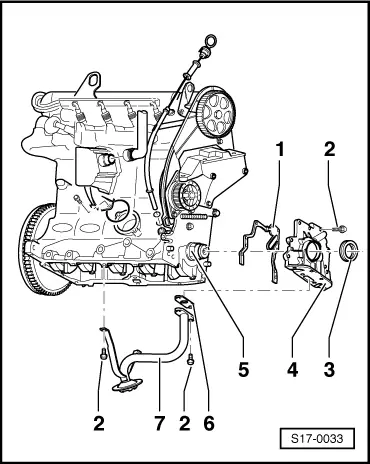

| 1 - | Cap |

| q | Replace seal if damaged |

| 2 - | Oil pressure switch (0.05 MPa) -F1-, 20 Nm |

| q | Switch range 0.03 ... 0.06 MPa |

| q | Identification: green |

| q | check → Chapter |

| q | Replace seal if damaged |

| 3 - | Guide tube |

| 4 - | Filler funnel |

| q | Remove for extracting oil |

| 5 - | Dipstick |

| q | oil level must not exceed max. marking! |

| 6 - | Camshaft sprocket |

| q | take note of the position when installing the timing belt → Chapter |

| 7 - | Oil filter |

| q | slacken with tensioning strap |

| q | Lightly oil gasket |

| q | 20 Nm |

| q | after topping up with oil, check for leaks |

| 8 - | Sprocket |

| 9 - | Tensioning pulley |

| q | Tensioning toothed belt → Chapter |

| 10 - | 20 Nm |

| 11 - | Timing belt |

| q | before removing mark running direction |

| q | check for wear |

| q | do not kink |

| q | removing and installing, tensioning → Chapter |

| 12 - | Timing belt guard - top part |

| 13 - | Timing belt guard - bottom part |

| 14 - | 20 Nm |

| 15 - | 90 Nm + torque a further 1/4 turn (90°) |

| q | replace |

| q | insert oiled |

| 16 - | Belt pulley |

| 17 - | Timing belt gear - crankshaft |

| q | take note of the position when installing the timing belt → Chapter |

| q | as of engine No. 210158 modified version, pay attention to the part number |

| 18 - | 10 Nm |

| 19 - | Gasket ring |

| q | replace → Chapter |

| q | as of engine No. 210158 modified version, pay attention to the part number |

| 20 - | Sealing flange/oil pump |

| q | as of engine No. 210158 with integrated oil pump ⇒ Fig. 4 |

| q | Removing and installing oil pump → Chapter |

| 21 - | Gasket |

| q | replace |

| 22 - | Sealing bush |

| q | replace if damaged |

| q | oil before assembly |

| q | first insert into sealing flange |

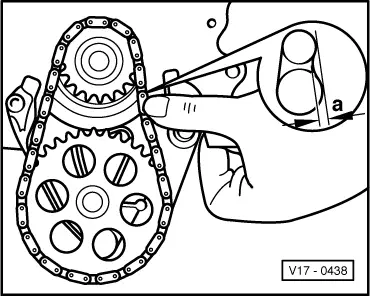

| 23 - | Chain |

| q | tensioning → Fig. |

| 24 - | Oil pump |

| q | Version up to engine No. 210157 |

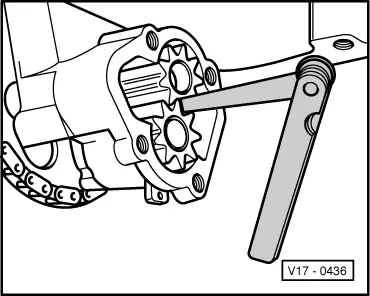

| q | Check tooth flange clearance → Fig. |

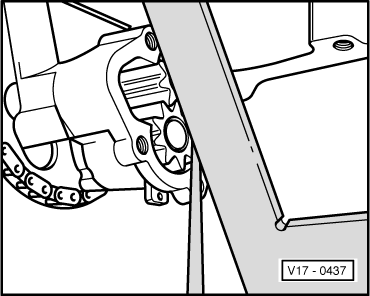

| q | inspecting axial play → Fig. |

| 25 - | Oil pump cover with pressure relief valve |

| q | Opening pressure: 4 ... 5 bar (0.40 ... 0.50 MPa) overpressure |

| q | Clean strainer if dirty |

| 26 - | Gasket ring |

| q | replace |

| 27 - | Oil drain plug, 20 Nm |

| 28 - | Oil pan |

| q | clean sealing surface before installing |

| 29 - | 15 Nm |

| 30 - | Support |

| 31 - | “O” ring |

| q | replace |

| 32 - | Oil separator |

| 33 - | Ventilation hose |

| q | To air filter |

|

|

|

|

|

|

|

|