| –

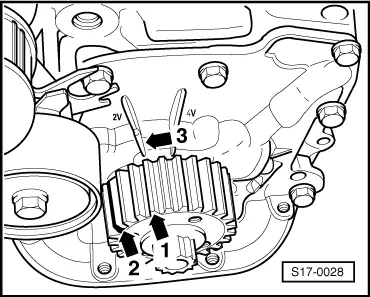

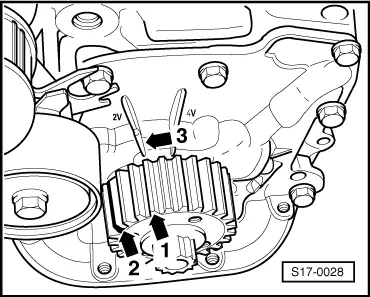

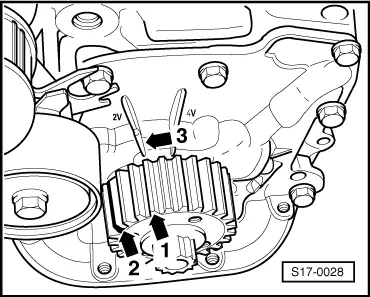

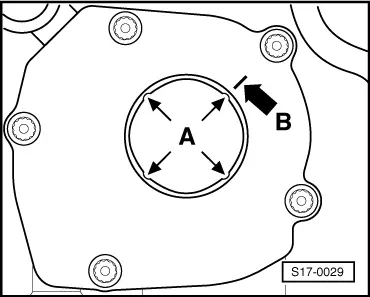

| Rotate crankshaft three teeth to the left from TDC marking. Use mirror. |

| 3. Right tooth -arrow 1- from chamfered tooth (TDC marking) -arrow 2- must be flush with the TDC marking on the oil pump housing (2V) -arrow 3- |

Note | Turning will give the crankshaft the fitting position for the oil pump. One of the four driver polygonal cams on the crankshaft is located at the top. |

| –

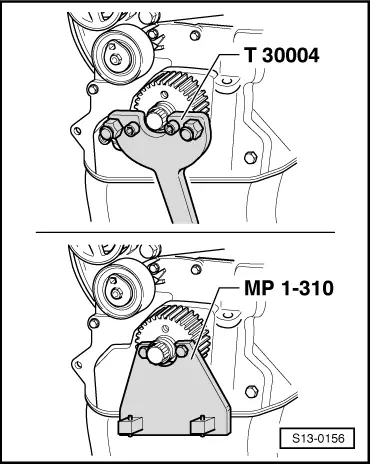

| Remove toothed belt gear-crankshaft and tensioning pulley of the toothed belt. |

| –

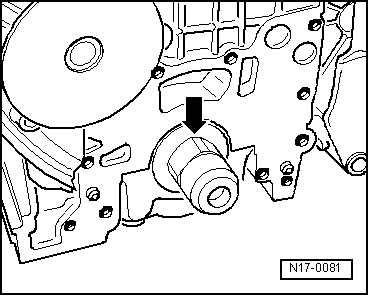

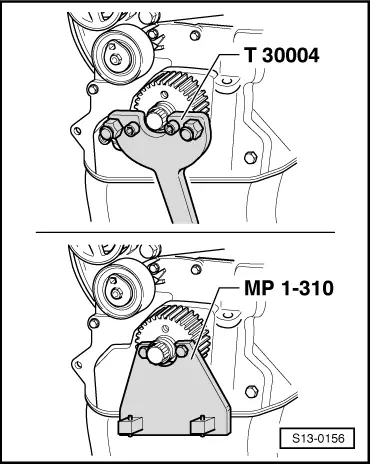

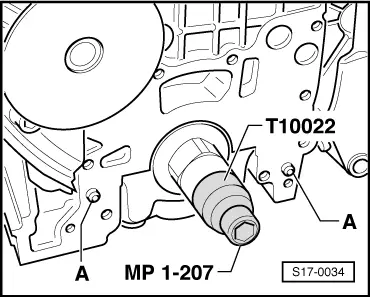

| Removing the suction line → Fig.. |

| –

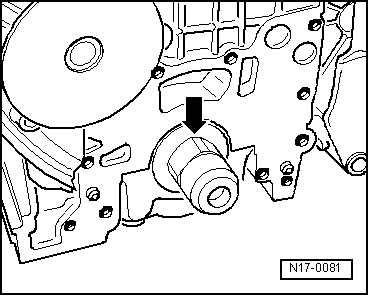

| Unscrew oil pump and separate from the crankshaft. |

| –

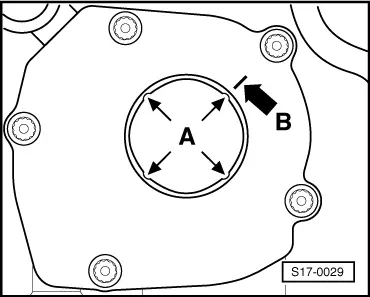

| Remove gasket on cylinder block, clean sealing surface. |

| –

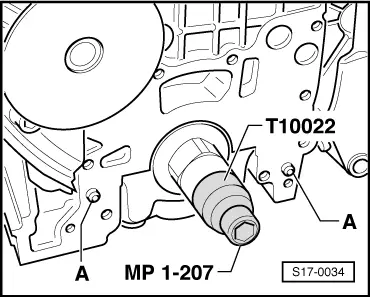

| When re-using the oil pump clean sealing surfaces (use a flat scraper to remove sealant residues); they must be free of oil and grease. |

Note | Before cleaning, the suction channel (suction line fixture) and the inner rotor of the oil pump must be covered on both sides, in order to avoid contamination of the oil pump. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note