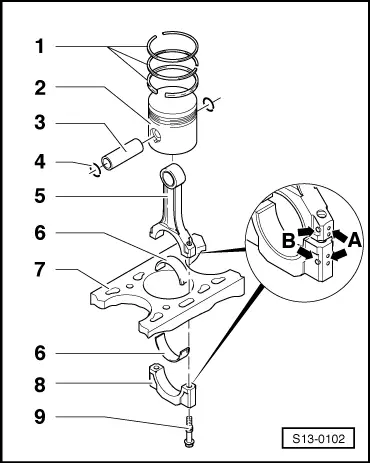

| Disassembling and assembling piston and conrod |

| –

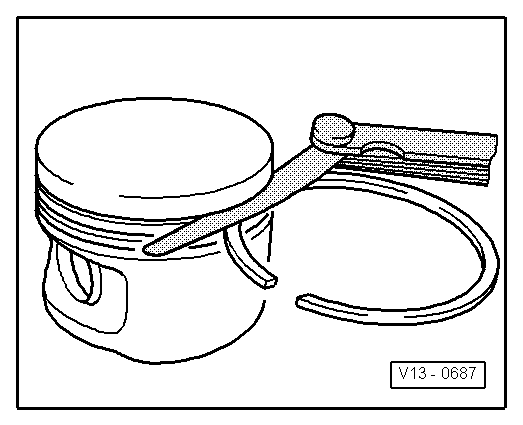

| use piston ring pliers for removing and installing |

| –

| marking “TOP” faces piston crown |

| –

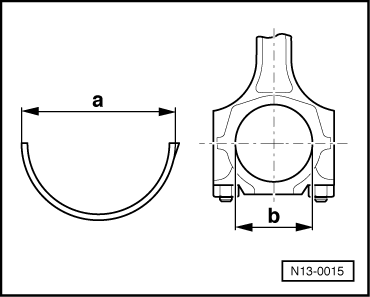

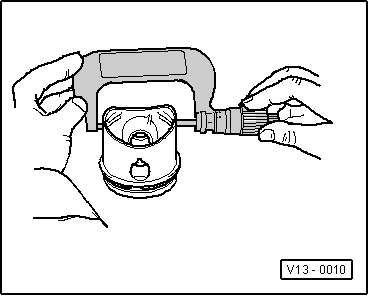

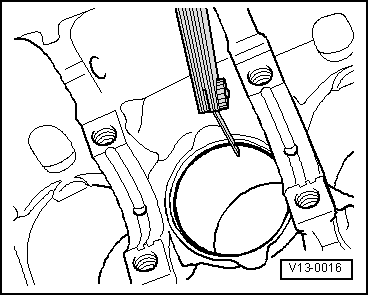

| inspect gap clearance → Fig. |

| –

| inspect end clearance → Fig. |

| –

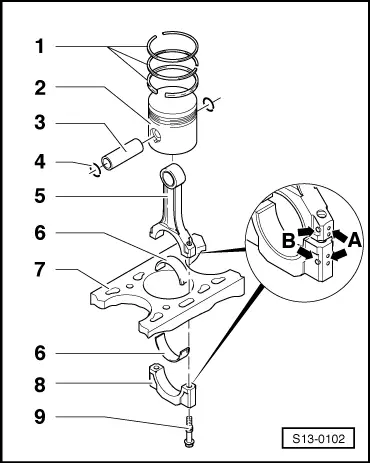

| mark installation position and matching cylinder |

| –

| arrow on piston crown faces towards the belt pulley side |

| –

| use piston ring tensioning strap for installing |

| –

| if stiff, heat piston to 60°C |

| –

| removing and installing with -MP 1-205- |

| –

| mark matching cylinder -A- |

| –

| Fitting position: Markings -B- point towards the belt pulley side |

| –

| Clean head contact surfaces with compressed air |

| –

| located axially by pistons |

| –

| do not mix up used bearing shells |

| –

| ensure tightly located in retaining lugs, so that the preload can be measured → Fig. |

| –

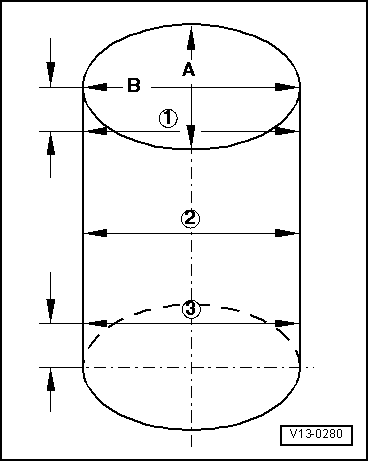

| inspect cylinder bore → Fig. |

| –

| Clean head contact surfaces with compressed air |

| 9 - | Conrod bolt, 30 Nm + torque a further 1/4 turn (90°) |

|

|

|

Note

Note