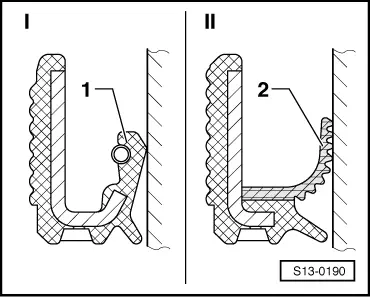

| I - Elastomer gasket ring |

|

| 1 Sealing lip -1-; with garter spring |

|

| multiple sealing lips -2-; without garter spring |

Note | t

| Do no moisten the PTFE gasket ring with oil before inserting. The shaft must also be free from oil and grease. |

| t

| Never install an elastomer gasket ring (old version), if a PTFE gasket ring (new version) was fitted. |

| t

| A PTFE gasket ring can be installed, if an elastomer gasket ring was installed. |

|

|

|

Note

Note

Note

Note