Octavia Mk1

|

| Display field | Displayed specified value | Corresponds to measured value | Denomination |

| 1 | 170 to 204 | 80 to 105°C | Coolant temperature (Precondition for basic setting) |

| 2 | 20 to 50 | 1.0 to 2.5 ms | Engine load (without consumers) |

| 3 | 76 to 841) 76 to 882) | 760 to 840 rpm1) 760 to 880 rpm2) | Engine speed (without consumers) |

| 4 | 146 to 212 | 10 to 14.5 V | Battery voltage |

| 5 | 0 to 12 | 0 to 5° | Throttle valve angle |

| 6 | 118 to 138 | -2.5 through +2.5 kg/h | Control value of idling air mass (idling regulator) |

| 7 | 112 to 144 | -4 through +4 kg/h | Initialisation value idling air mass |

| 8 | 78 to 178 | -10 to +10% | Control value of the fuel preparation (lambda control value) additive (if outside tolerance, perform test drive) |

| 9 | 243 to 255 or 0 to +131) 0 to +122) | -0.64 to +0.64 ms | Initialisation value of the fuel preparation (lambda initialisation value) (if outside tolerance, perform test drive) |

| 10 | 118 to 138 | -8 to +8% | Initialisation value of the fuel preparation (lambda initialisation value) multiplicative (if outside tolerance, perform test drive) |

Note

Note

|

| Display field | Display -V.A.G 1552 - | Fault cause | Rectifying fault | ||||

| 1 | greater than 204 |

|

| ||||

| |||||||

| less than 170 |

|

| |||||

| |||||||

|

| ||||||

| 2 | greater than 50 |

|

| ||||

|

| ||||||

|

| ||||||

|

| ||||||

| less than 20 |

|

| |||||

| |||||||

| |||||||

| |||||||

| 3 | less than 76 |

|

| ||||

|

| ||||||

|

| ||||||

| greater than 841) greater than 882) |

|

| |||||

|

| ||||||

|

|

|

| Display field | Display -V.A.G 1552 - | Fault cause | Rectifying fault | |||||

| 4 | less than 146 |

|

| |||||

|

| |||||||

|

| |||||||

| .

| |||||||

| greater than 212 |

|

| ||||||

|

| |||||||

| 5 | less than 0 |

| ||||||

| greater than 12 |

|

| ||||||

|

| |||||||

|

| |||||||

| 6 | less than 118 |

|

| |||||

| greater than 138 |

|

| ||||||

| 7 | less than 112 |

|

| |||||

| greater than 144 |

|

| ||||||

| 8 | less than 78 |

|

| |||||

| ||||||||

|

| |||||||

|

| |||||||

| greater than 178 |

|

| ||||||

|

| |||||||

| ||||||||

|

| |||||||

| Display switches or remains contact at 128 |

|

| ||||||

| 9 | less than 243 or greater than 131) greater than 122) |

| ||||||

| 10 | less than 118 or greater than 138 |

|

|

| Read measured value block 1 → | ← Readout on display | |||||

| xxx rpm | 1.0...2.5 ms | 0...5∠° | XX.X° BTDC | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Ignition angle | ? 07.97 : 3 to 12° b. TDC (b. TDC) 08.97 ? : 6 to 12° b. TDC (b. TDC) | |||||

| Throttle valve angle Readout when accelerator pedal fully depressed is 80 to 90 ∠° as soon as a fault is detected at the throttle valve potentiometer, a fixed replacement value of 35 ∠° is displayed | ||||||

| Engine load (injection time per crankshaft rotation) | ||||||

| Idling speed | ? 07.97 : 760 to 840 rpm 08.97 ? : 760 to 880 rpm | |||||

|

| Display field | Display -V.A.G 1552 - | Fault cause | Rectifying fault | ||||

| 1 | less than 760 rpm |

|

| ||||

|

| ||||||

|

| ||||||

| greater than 840 rpm 1) greater than 880 rpm 2) |

|

| |||||

|

| ||||||

|

| ||||||

|

| ||||||

| 2 | less than 1.0 |

| |||||

| greater than 2.5 |

|

| |||||

|

| ||||||

|

| ||||||

|

| ||||||

|

| ||||||

|

| ||||||

| 3 | greater than 5 ∠° |

|

| ||||

|

| ||||||

|

| ||||||

|

| ||||||

| 4 | less than 3° b. TDC 1) less than 6° b. TDC 2) |

|

| ||||

|

| ||||||

|

| ||||||

| greater than 12° b. TDC |

|

|

Note

Note

|

| Read measured value block 2 → | ← Readout on display | |||||

| xxx rpm | 1.0...2.5 ms | 2.0...5.0 ms | 2.0...4.0 g/s | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Drawn in air mass | ||||||

| corrected injection time per working cycle | ||||||

| Engine load (injection time per crankshaft rotation) | ||||||

| Idling speed | ? 07.97 : 760 to 840 rpm 08.97 ? : 760 to 880 rpm | |||||

|

| Display field | Display -V.A.G 1552 - | Fault cause | Rectifying fault | ||||

| 1 |

| ||||||

| 2 |

| ||||||

| 3 | less than 2.0 |

|

| ||||

|

| ||||||

| greater than 5.0 |

|

| |||||

| 4 | less than 2.0 |

|

| ||||

| greater than 4.0 |

|

| |||||

|

|

Note

Note

|

| Read measured value block 3 → | ← Readout on display | |||||

| xxx rpm | 10.0...14.5 V | 80...105 °C | ... °C | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Intake manifold temperature | ||||||

| Coolant temperature | ||||||

| Battery voltage | ||||||

| Idling speed | ? 07.97 : 760 to 840 rpm 08.97 ? : 760 to 880 rpm | |||||

Note

Note

|

| Display field | Display -V.A.G 1552 - | Fault cause | Rectifying fault | ||||

| 1 |

| ||||||

| 2 | below 10 V |

|

| ||||

|

| ||||||

|

| ||||||

|

| ||||||

| greater than 14.5 V |

|

| |||||

|

| ||||||

| 3 | below 80°C |

|

| ||||

|

| ||||||

| above 105°C |

|

| |||||

|

| ||||||

|

| ||||||

|

| ||||||

| 4 | constant 19.5°C |

|

| ||||

|

|

Note

Note

|

| Read measured value block 4 → | ← Readout on display | |||||

| 0....5 ∠° | -1.7..+1.7 g/s | -1.7..+1.7 g/s | Idling | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Operating state (idling, part load, full load, enrichment, overrun) | ||||||

| Idling air mass initialised with engaged driving position (for vehicles with an automatic gearbox) on vehicles with manual gearbox 0 is always displayed | ||||||

| Idling air mass initialised (without driving position for vehicles with an automatic gearbox) | ||||||

| Throttle valve angle | ||||||

|

| Display field | Display -V.A.G 1552 - | Fault cause | Rectifying fault | ||||

| 1 | see test table - display group 001, display field 3 → Chapter | ||||||

| 2 | lower than -1.7 g/s |

|

| ||||

| higher than +1.7 g/s |

|

| |||||

|

|

Note

Note

|

| Read measured value block 5 → | ← Readout on display | |||||

| XXX rpm | 800/860 rpm | -10,0...10,0 % | 2.0...4.0 g/s | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Air mass | ||||||

| Idling regulator | ||||||

| Engine speed (nominal) is displayed in ten steps manual gearbox: 800 rpm (AC system off) manual gearbox: 860 rpm (AC system on) automatic gearbox: 800 rpm (AC system off) automatic gearbox: 860 rpm (AC system on) | ||||||

| Idling speed | ? 07.97 : 760 to 840 rpm 08.97 ? : 760 to 880 rpm | |||||

| Maximum value: 2550 rpm | ||||||

| Read measured value block 6 → | ← Readout on display | |||||

| XXX rpm | -10,0...10,0 % | -10,0...10,0 % | XX.X° BTDC | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Ignition angle | ? 07.97 : 3 to 12° b. TDC (b. TDC) 08.97 ? : 6 to 12° b. TDC (b. TDC) | |||||

| Lambda regulator | ||||||

| Idling regulator | ||||||

| Idling speed | ? 07.97 : 760 to 840 rpm 08.97 ? : 760 to 880 rpm | |||||

|

| Display field | Display -V.A.G 1552 - | Fault cause | Rectifying fault | ||||

| 1 | see test table - display group 001, display field 1 → Chapter | ||||||

| 2 | see test table - display group 005, display field 3 → Anchor | ||||||

| 3 | not within tolerance |

| |||||

|

| ||||||

|

| ||||||

|

| ||||||

| 4 | see test table - display group 001, display field 4 → Chapter |

Note

Note

|

| Read measured value block 7 → | ← Readout on display | |||||

| -10,0...10,0 % | 0.0...1.0 V | 0...99% | 0,3 ...1,25 | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Lambda correction factor for active fuel tank ventilation | ||||||

| On/Off ratio of solenoid valve 1 for activated charcoal filter -N80- On/Off ratio 0% means -N80- closed On/Off ratio 99% means -N80- fully open | ||||||

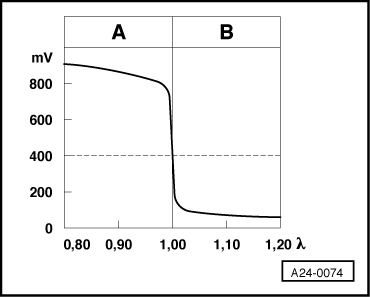

| Lambda probe voltage | ||||||

| Lambda regulator | ||||||

|

| Display field | Display -V.A.G 1552 - | Fault cause | Rectifying fault | ||||

| 2 | If the display does not fluctuate (constant 0.00 to 0.30 V or constant 0.70 to 1.00 V) |

|

| ||||

|

| ||||||

|

| ||||||

|

| ||||||

|

| ||||||

|

| ||||||

|

| ||||||

|

| ||||||

| constant 1.00 V |

lambda probe cable, earth lead, engine control unit |

| |||||

| constant between 0.40 to 0.50 V |

lambda probe cable, earth lead, engine control unit |

| |||||

| constant 0.00 V |

lambda probe cable, earth lead, engine control unit |

Note

Note

Note

Note

|

|

|

| Read measured value block 8 → | ← Readout on display | |||||

| 2.0...5.0 ms | -10,0...10,0 % | -8,0...8,0 % | TV active or TV not active or λ adaptation | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| “TV active” means, that the activated charcoal filter system solenoid valve 1 is pulsed (6 to 16 min) “TV not active” means, that the activated charcoal filter system solenoid valve 1 is closed constantly (1 min) “λ adaptation” means the correction of the voltage curve displacement resulting from the lambda probe ageing. | ||||||

| Lambda learned value at partial load (multiplicative) | ||||||

| Lambda learned value at idling speed (additive) | ||||||

| Injection period | ||||||

|

| Display field | Display -V.A.G 1552 - | Fault cause | Rectifying fault | ||||||

| 1 | see test table - display group 002, display field 3 → Chapter | ||||||||

| 2 and 3 | low lambda learned values |

|

| ||||||

|

| ||||||||

|

| ||||||||

|

| ||||||||

|

| ||||||||

|

| ||||||||

| high lambda initialisation values |

|

| |||||||

|

| ||||||||

|

| ||||||||

|

| ||||||||

|

| ||||||||

| |||||||||

|

|

Note

Note

|

| Read measured value block 9 → | ← Readout on display | |||||

| XXX rpm | - 10... + 10 % | 0...1.0 V | - 10... + 10 % | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Lambda learned value at idling speed (additive) | ||||||

| Lambda probe voltage | ||||||

| Lambda regulator | ||||||

| Idling speed | ? 07.97 : 760 to 840 rpm 08.97 ? : 760 to 880 rpm | |||||

|

| Read measured value block 10 → | ← Readout on display | |||||||||

| 0....99 % | 0,3...1,25 | 3...321) -5...452) | 0,00...0,30 | |||||||

| 1 | 2 | 3 | 4 | ← Display field | ||||||

Activated charcoal filter - rinse rate (ACF):

| ||||||||||

Volumetric efficiency of activated charcoal filter system:

| ||||||||||

| Lambda correction factor for active fuel tank ventilation | ||||||||||

| On/Off ratio of solenoid valve 1 for activated charcoal filter (ACF) | ||||||||||

Note

Note

Note

Note

Note

Note

|

| Read measured value block 11 → | ← Readout on display | |||||

| XXX rpm | 1.0...2.5 ms | 0 km/h | 0.5...1.5 l/h | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Fuel consumption: the display specified value applies only for idle without load due to auxiliary equipment (automatic gearbox, air conditioning system, generator, gear pump). | ||||||

| Driving speed | ||||||

| Engine load | ||||||

| Idling speed | ? 07.97 : 760 to 840 rpm 08.97 ? : 760 to 880 rpm | |||||

Note

Note

|

| Read measured value block 12 → | ← Readout on display | |||||

| XXX rpm | 10...14.5 V | 0.5...1.5 l/h | XX.X° BTDC | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Ignition angle | ? 07.97 : 3 to 12° b. TDC (b. TDC) 08.97 ? : 6 to 12° b. TDC (b. TDC) | |||||

| Fuel consumption - see display group 011, display field 4 | ||||||

| Battery voltage - see display group 003, display field 2 | ||||||

| Idling speed | ? 07.97 : 760 to 840 rpm 08.97 ? : 760 to 880 rpm | |||||

|

| Read measured value block 13 → | ← Readout on display | |||||

| 0...15° KW | 0...15° KW | 0...15° KW | 0...15° KW | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Ignition angle relief cylinder 4 through knock control | ||||||

| Ignition angle relief cylinder 3 through knock control | ||||||

| Ignition angle relief cylinder 2 through knock control | ||||||

| Ignition angle relief cylinder 1 through knock control | ||||||

Note

Note

|

| Read measured value block 14 → | ← Readout on display | |||||

| 0...6800 rpm | 0...10.0 ms | 0...15° KW | 0...15° KW | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Ignition angle relief cylinder 2 through knock control | ||||||

| Ignition angle relief cylinder 1 through knock control | ||||||

| Engine load (injection time per rotation) | ||||||

| Engine speed | ||||||

Note

Note

|

| Read measured value block 15 → | ← Readout on display | |||||

| 0...6800 rpm | 0...10.0 ms | 0...15° KW | 0...15° KW | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Ignition angle relief cylinder 4 through knock control | ||||||

| Ignition angle relief cylinder 3 through knock control | ||||||

| Engine load (injection time per rotation) | ||||||

| Engine speed | ||||||

Note

Note

|

| Read measured value block 16 → | ← Readout on display | |||||

| 0.4...2.0 V | 0.4...2.0 V | 0.4...2.0 V | 0.4...2.0 V | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Knock sensor of cylinder 4 | ||||||

| Knock sensor of cylinder 3 | ||||||

| Knock sensor of cylinder 2 | ||||||

| Knock sensor of cylinder 1 | ||||||

Note

Note

|

| Read measured value block 17 → | ← Readout on display | |||||

| 0...6800 rpm | 1.0...2.5 ms | 0...100 % | XX.X° BTDC | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Ignition angle | ||||||

| Overview of energy consumption for CAT heating | ||||||

| Engine load (injection time per crankshaft rotation) | ||||||

| Engine speed | ||||||

Note

Note

|

| Read measured value block 18 → | ← Readout on display | |||||

| XXX rpm | 1.0...2.5 ms | 0.5...3 ms | -50...+15 % | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Level correction factor | ||||||

| Engine load from throttle valve angle | ||||||

| Engine load from air mass meter see display group 001, display field 2 | ||||||

| Idling speed | ? 07.97 : 760 to 840 rpm 08.97 ? : 760 to 880 rpm | |||||

Note

Note

|

| Read measured value block 19 → | ← Readout on display | |||||

| 0...6800 rpm | ms | X 1 X | °KW | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Ignition angle | ||||||

| Operating condition: X 1 X = no gearbox intervention signal X 0 X = gearbox intervention signal X = Display without meaning | ||||||

| Engine load | ||||||

| Engine speed | ||||||

Note

Note

|

| Read measured value block 19 → | ← Readout on display | |||||

| 0...6800 rpm | 0...10.00 ms | xxxx_x | °KW | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Ignition angle | ||||||

| Additional signals 0xxx_x = Power steering pressure switch xx0x_x = Ignition angle relief active xxx0_x = Clutch pedal switch active | ||||||

| Engine load | ||||||

| Engine speed | ||||||

Note

Note

|

| Read measured value block 20 → | ← Readout on display | |||||

| XXX rpm | Neutral driving position ON | A/C High A/C Low | Compr. ON Compr. OFF | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| AC compressor ON/OFF vehicles not fitted with air conditioning system always indicate “Compr. OFF” | ||||||

| Air conditioning system High = high heat or cooling power output Low = low heat or cooling power output vehicles not fitted with air conditioning system always indicate “A/C-Low” | ||||||

| Selector lever position, neutral or driving position ON vehicles fitted with manual gearbox always indicate “Neutral” | ||||||

| Idling speed | ? 07.97 : 760 to 840 rpm 08.97 ? : 760 to 880 rpm | |||||

|

| Read measured value block 21 → | ← Readout on display | |||||

| XXX rpm | 1.0...2.5 ms | XXX °C | Reg. λ-off. Reg. λ-on. | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Lambda control ON/OFF | ||||||

| Coolant temperature | ||||||

| Engine load - see display group 001, display field 2 | ||||||

| Idling speed | ? 07.97 : 760 to 840 rpm 08.97 ? : 760 to 880 rpm | |||||

Note

Note

|

| Read measured value block 23 → | ← Readout on display | |||||

| 01000000 | 73...97 % | 54...85 % | 6...43 % | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| max limit of throttle valve positioner -V60- | ||||||

| Emergency limit of throttle valve positioner - V60- | ||||||

| min. limit of throttle valve positioner - V60- | ||||||

| Initialisation need display | ||||||

Note

Note

|

| X | X | X | X | X | X | X | X | Meaning of 8-digit display | |

| 1 = | no meaning | ||||||||

| 2 = | Learning process min. limit of throttle valve positioner sender - G127- value “0” = learning process performed, learning process o.k. value “1” = learning process not performed, learning process n.o.k. | ||||||||

| 3 = | Learning process max. limit of throttle valve positioner sender - G127- value “0” = learning process performed, learning process o.k. value “1” = learning process not performed, learning process n.o.k. | ||||||||

| 4 = | Learning process min. limit of throttle valve potentiometer -G69- value “0” = learning process performed, learning process o.k. value “1” = learning process not performed, learning process n.o.k. | ||||||||

| 5 = | Learning process max. limit of throttle valve potentiometer -G69- value “0” = learning process performed, learning process o.k. value “1” = learning process not performed, learning process n.o.k. | ||||||||

| 6 = | no meaning | ||||||||

| 7 = | Balance throttle valve potentiometer -G69- with throttle valve positioner sender -G127- value “0” = Balance must be performed value “1” = Balance performed, balance o.k. | ||||||||

| 8 = | no meaning | ||||||||

|

| Read measured value block 23 → | ← Readout on display | |||||

| 100000 | 73...97 % | 54...85 % | 6...43 % | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| max limit of throttle valve positioner -V60- | ||||||

| Emergency limit of throttle valve positioner - V60- | ||||||

| min. limit of throttle valve positioner - V60- | ||||||

| Initialisation need display | ||||||

Note

Note

|

| X | X | X | X | X | X | Meaning of 6-digit display | |

| 1 = | Learning process min. limit of throttle valve positioner sender -G127- value “0” = learning process performed, learning process o.k. value “1” = learning process not performed, learning process n.o.k. | ||||||

| 2 = | Learning process max. limit of throttle valve positioner sender -G127- value “0” = learning process performed, learning process o.k. value “1” = learning process not performed, learning process n.o.k. | ||||||

| 3 = | Learning process min. limit of throttle valve potentiometer -G69- value “0” = learning process performed, learning process o.k. value “1” = learning process not performed, learning process n.o.k. | ||||||

| 4 = | Learning process max. limit of throttle valve potentiometer -G69- value “0” = learning process performed, learning process o.k. value “1” = learning process not performed, learning process n.o.k. | ||||||

| 5 = | no meaning | ||||||

| 6 = | Balance throttle valve potentiometer -G69- with throttle valve positioner sender -G127- value “0” = Balance must be performed value “1” = Balance performed, balance o.k. | ||||||

|

| Read measured value block 24 → | ← Readout on display | |||||

| 0...6800 rpm | 0...10.00 ms | 20°a. TDC 42° b. TDC | 0...36.0 °KW | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| Total of the ignition angle relief cylinder 1 to 4 | ||||||

| Ignition angle | ||||||

| Engine load | ||||||

| Engine speed | ||||||

Note

Note

|

| Read measured value block 25 → | ← Readout on display | |||||

| Idling | - 30...+ 30 ° KW | X XX | - 3....+ 22 ° KW | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| active camshaft adjustment angle camshaft in normal position = -3.0 to 3.0° KW camshaft in switched position = 15.0 to 22.0° KW | ||||||

| Operating condition: Camshaft adjustment | ||||||

| Setting tolerance of phase sender (Hall sender) | ||||||

| Operating position | ||||||

|

| X | X | X | Meaning | |||||

| Value “0” = condition not fulfilled, actuation not active value “1” = condition fulfilled, actuation active | ||||||||

| Camshaft adjustment (1 = “early adjustment”, power output position) | ||||||||

| no meaning | ||||||||

| not assigned | ||||||||

| no meaning | ||||||||

Note

Note

|

| Read measured value block 25 → | ← Readout on display | |||||

| Idling | - 30...+ 30 ° KW | X XX | - 3....+ 22 ° KW | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| active camshaft adjustment angle camshaft in normal position = -3.0 to 3.0° KW camshaft in switched position = 15.0 to 22.0° KW | ||||||

| Operating condition: Variable intake manifold changeover Camshaft adjustment | ||||||

| Setting tolerance of phase sender (Hall sender) | ||||||

| Operating position | ||||||

Note

Note

|

| X | X | X | Meaning | |||||

| Value “0” = condition not fulfilled, actuation not active value “1” = condition fulfilled, actuation active | ||||||||

| Camshaft adjustment (1 = “early adjustment”, power output position) | ||||||||

| Variable intake manifold changeover (1 = long suction path, torque position) | ||||||||

| not assigned | ||||||||

| no meaning | ||||||||

|

| Read measured value block 26 → | ← Readout on display | |||||

| 0...4500 rpm | 0...10.00 ms | X XX | - 3....+ 22 ° KW | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| active camshaft adjustment angle camshaft in normal position = -3.0 to 3.0° KW camshaft in switched position = 15.0 to 22.0° KW | ||||||

| Operating condition: Camshaft adjustment | ||||||

| Engine load - see display group 001, display field 2 | ||||||

| Engine speed | ||||||

Note

Note

|

| X | X | X | Meaning | |||||

| Value “0” = condition not fulfilled, actuation not active value “1” = condition fulfilled, actuation active | ||||||||

| Camshaft adjustment (1 = “early adjustment”, power output position) | ||||||||

| no meaning | ||||||||

| not assigned | ||||||||

| no meaning | ||||||||

|

| Read measured value block 26 → | ← Readout on display | |||||

| 0...4500 rpm | 0...10.00 ms | X XX | - 3....+ 22 ° KW | |||

| 1 | 2 | 3 | 4 | ← Display field | ||

| active camshaft adjustment angle camshaft in normal position = -3.0 to 3.0° KW camshaft in switched position = 15.0 to 22.0° KW | ||||||

| Operating condition: Variable intake manifold changeover Camshaft adjustment | ||||||

| Engine load - see display group 001, display field 2 | ||||||

| Engine speed | ||||||

|

| X | X | X | Meaning | |||||

| Value “0” = condition not fulfilled, actuation not active value “1” = condition fulfilled, actuation active | ||||||||

| Camshaft adjustment (1 = “early adjustment”, power output position) | ||||||||

| Variable intake manifold changeover (1 = long suction path, torque position) | ||||||||

| not assigned | ||||||||

| no meaning | ||||||||

Note

Note

|