Octavia Mk1

|

|

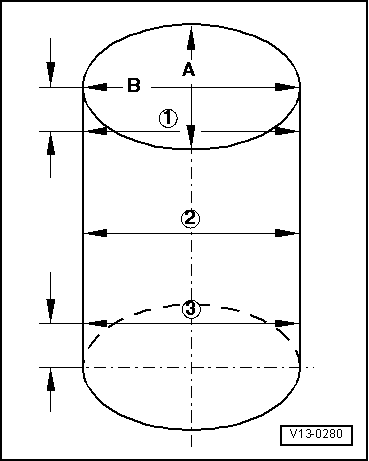

| Piston ring dimensions in mm | new | Wear limit |

| 1. Compression ring | 0,20...0,40 | 1,0 |

| 2. Compression ring | 0,20...0,40 | 1,0 |

| Oil scraper ring | 0,25...0,50 | 1,0 |

|

|

| Piston ring dimensions in mm | new | Wear limit |

| 1. Compression ring | 0,06...0,09 | 0,25 |

| 2. Compression ring | 0,05...0,08 | 0,25 |

| Oil scraper ring | 0,03...0,06 | 0,15 |

Note

Note

|

|

Note

Note

|

|