Octavia Mk1

| Removing and installing crankshaft |

| 1 - | Bearing shells 1, 2, 4 and 5 |

| q | for bearing cap without lubricating groove |

| q | for cylinder block with lubricating groove |

| q | do not mix up used bearing shells (mark) |

| 2 - | 65 Nm + torque a further 90° (1/4 turn) |

| q | replace |

| q | tighten thread |

| 3 - | Bearing caps |

| q | Bearing cap 1: on the belt pulley side |

| q | Bearing cap 3: with recesses for thrust washers |

| q | retaining lugs of the bearing shells of the cylinder block/bearing cap must be on top of one another |

| 4 - | Bearing shell 3 |

| q | for bearing cap without lubricating groove |

| q | for cylinder block with lubricating groove |

| 5 - | Thrust washer |

| q | for bearing cap 3 |

| q | pay attention to locating element |

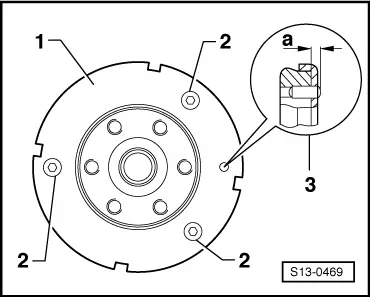

| 6 - | Pulse rotor |

| q | for engine speed sender -G28- |

| q | replace if damaged |

| q | replace each time the fixing bolts are slackened |

| q | Assembly only possible in one position - holes offset |

| q | removing and installing → Fig. |

| 7 - | 10 Nm + torque a further 90° (1/4 turn) |

| q | replace |

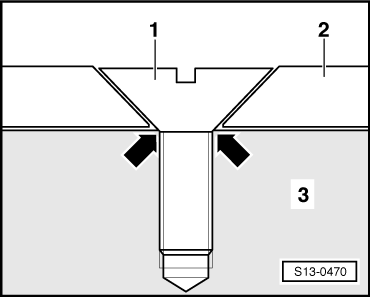

| 8 - | Fit pin |

| q | Checking projection from crankshaft → Fig. |

| 9 - | Crankshaft |

| q | Pay attention to the part number |

| q | with chain sprocket for oil pump drive |

| q | Crankshaft bearing journal: Ø 54.00 mm |

| q | Conrod bearing journal: Ø 47.80 mm |

| q | Axial play when new: 0.07...0.17 mm |

| q | Wear limit: 0.37 mm |

| 10 - | Thrust washer |

| q | for cylinder block, bearing 3 |

Note

Note

|

|