| Reworking inlet valve seat |

| –

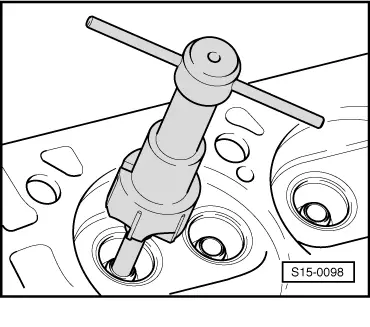

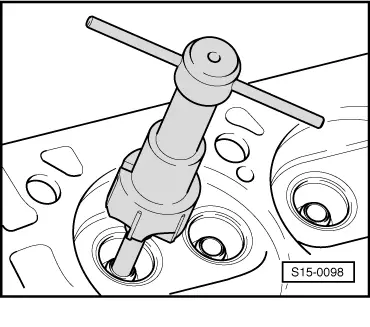

| Mill valve seat with 90° milling cutter until a perfect contact pattern is achieved. (Do not exceed maximum permissible reworking dimension!) |

| –

| Chamfer bottom correction angle with 60° milling cutter until the valve seat diameter -a- → Chapter is achieved. |

| –

| Mill bottom correction angle with 150° milling cutter until valve seat width -c- is achieved → Chapter. |

| Reworking exhaust valve seat |

| –

| Mill valve seat with 90° milling cutter until a perfect contact pattern is achieved. (Do not exceed maximum permissible reworking dimension!) |

| –

| Measure achieved seat width with caliper gauge: |

| If the measured dimension is less than the nominal value: |

| –

| Chamfer valve seat with 90° milling cutter until valve seat width -c- is achieved → Chapter. (Do not exceed maximum permissible reworking dimension!) |

| If the measured dimension is more than the nominal value: |

| –

| Mill bottom correction angle with 150° milling cutter until valve seat width -c- is achieved → Chapter. |

|

|

|