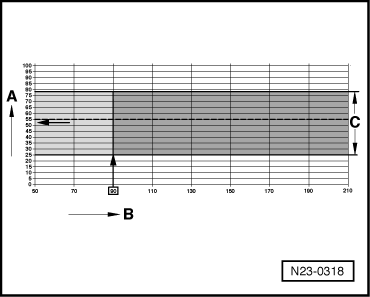

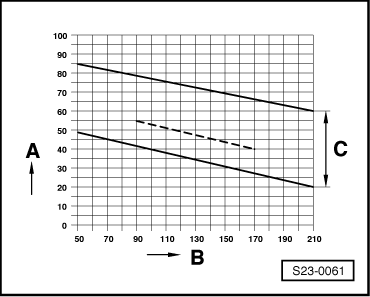

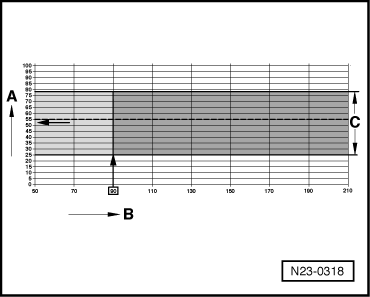

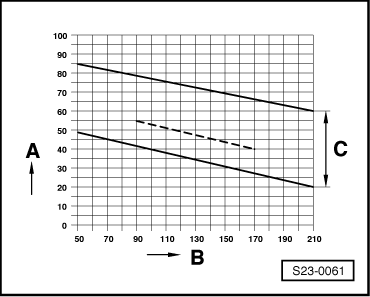

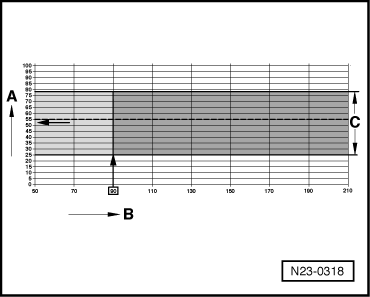

| Nominal value ⇒ figure - range C |

| A - | Display field 2, commencement of injection |

| B - | Display field 9, fuel temperature |

| C - | Nominal value for commenecement of injection |

Note | No setting is required if during testing the commencement of injection is in the nominal value range -C-. The commencement of injection must be set to the middle value after replacing the injection pump and the engine control unit. |

| If the commencement of injection is outside the nominal range, set the injection pump in accordance with the figure: |

| –

| Remove top toothed belt guard. |

| –

| Test toothed belt voltage. |

| The markings on the tensioning pulley must be opposite one another. |

| If markings are not positioned opposite: |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note