| –

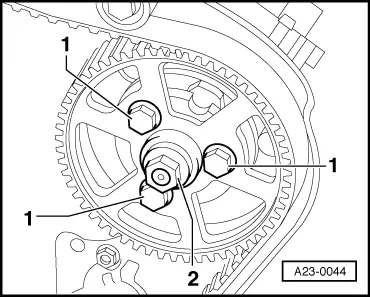

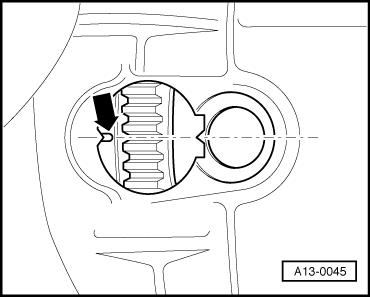

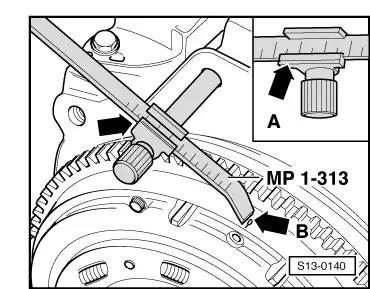

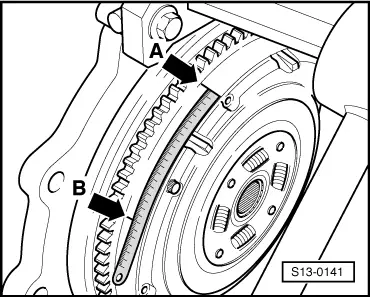

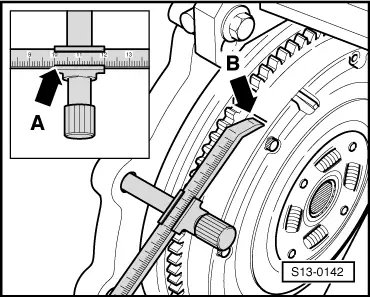

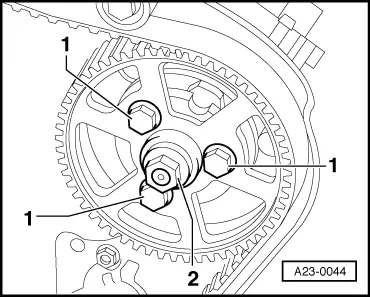

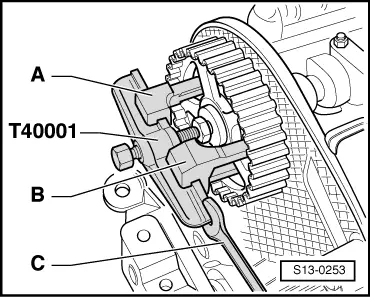

| Loosen fixing bolts -1- of the injection pump gear. |

Note | t

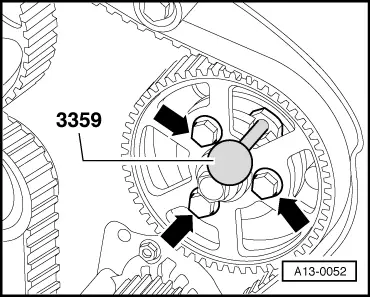

| Use rig pin -3359- to counterhold the injection pump gear → Anchor, fig A13-0052. |

| t

| Rig pin must be moistened with oil each time in use. It is recommended to use a mirror in order to facilitate the removal. |

| t

| If it is not possible to unlock the injection pump gear with the rig pin, the crankshaft must be turned in such a way that the bore holes for the rig pin are aligned. Then, loosen the screws of the injection pump gear and only then position the crankshaft to TDC. |

| t

| Never release the central nut -2- of the injection pump gear. This could result in a misadjustment of the basic setting of the injection pump which can no longer be corrected with workshop tools. |

| –

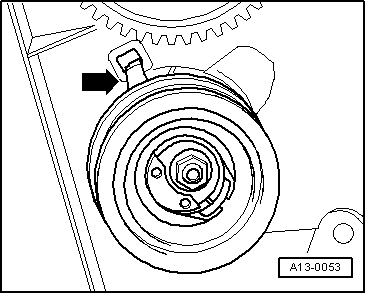

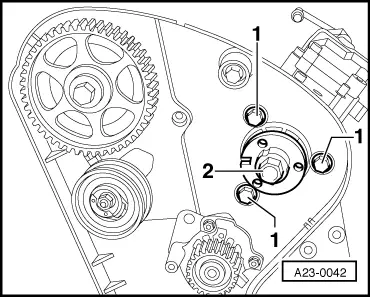

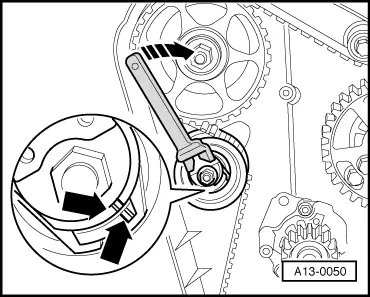

| Unscrew nut for tensioning pulley. |

| –

| Remove toothed belt from the camshaft sprockets and the injection pump gear. |

| –

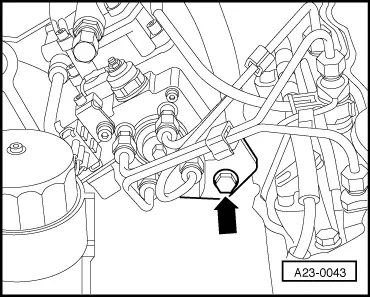

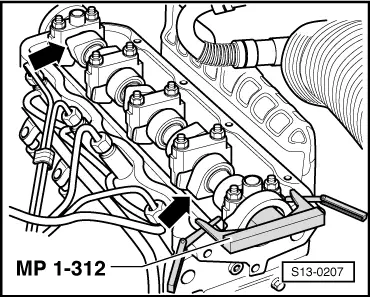

| Disconnect the plug connection for the electrical connections of the injection pump. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note