Octavia Mk1

|

Note

Note| This is the only adjusting work when installing an exchange component → Chapter. |

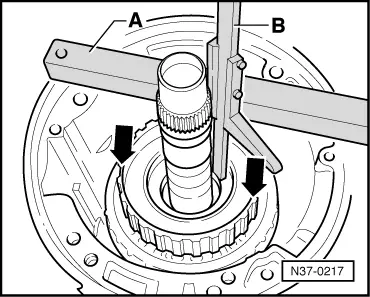

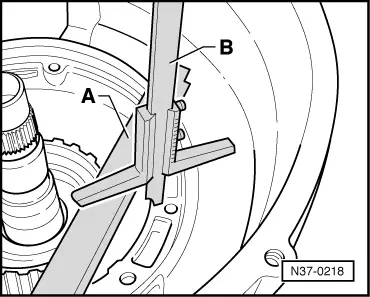

| – | Install components for adjusting the clutch clearance without adjusting washer Pos. 4 and reverse gear-clutch Pos. 5. |

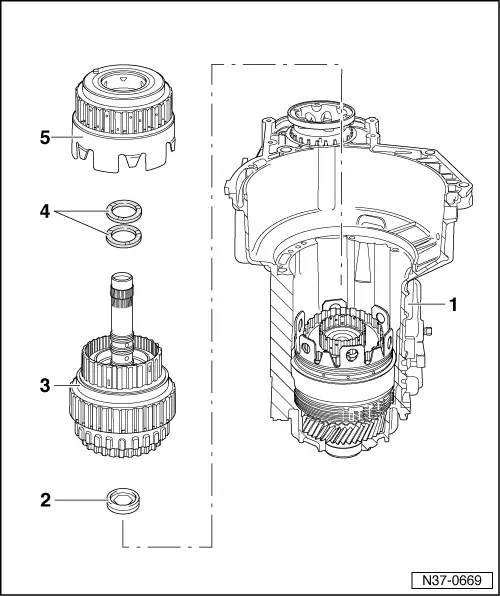

| 1 - | Gearbox housing |

| q | Planetary gear fitted up to small drive shaft → Anchor |

| 2 - | Axial needle bearing with washer |

| q | Axial needle bearing points to the small drive shaft |

| q | Washer points to -K3- |

| 3 - | 1st up to 3rd gear - clutch -K1- with 3rd and 4th gear - clutch -K3- with turbine shaft |

| q | on certain gearboxes, the clutches -K1- and -K3- can be pressed together as shown here |

| q | there are two different versions of turbine shafts, depending on the installed converter → Chapter |

| 4 - | Shims |

| q | do not install to adjust the clutch clearance |

| q | up to 3 adjusting washers can be installed |

| q | washers are available in different colours depending on the thickness |

| 5 - | Reverse gear - clutch -K2- |

| q | must not be installed necessarily for determining the adjusting washer(s) |

| q | install for control measurement |

|

|

|

|

|

|

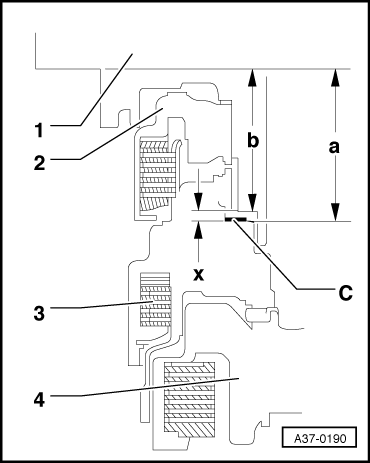

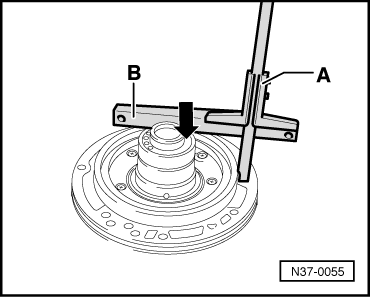

| Measured value 1 | = | 88.5 mm |

| - Measured value 2 | = | - 34.3 mm |

| determined value “a” | = | 54.2 mm |

|

|

|

| measured value | = | 70.5 mm |

| - Straightedge | = | - 19.5 mm |

| determined value “b” | = | 51.0 mm |

|