| –

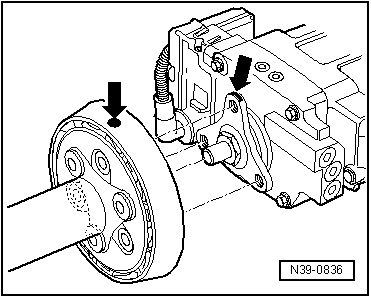

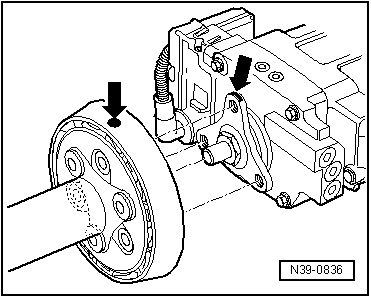

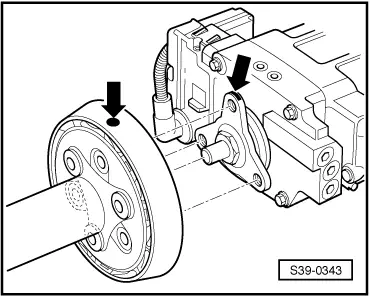

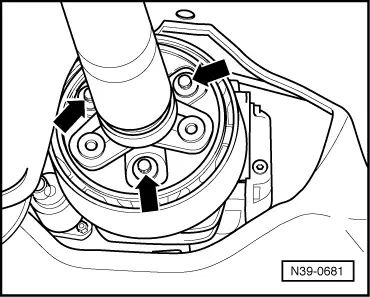

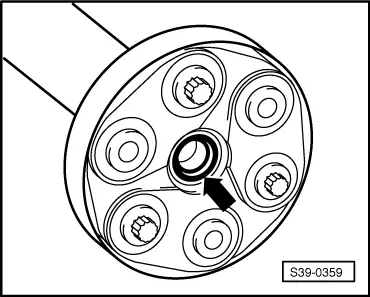

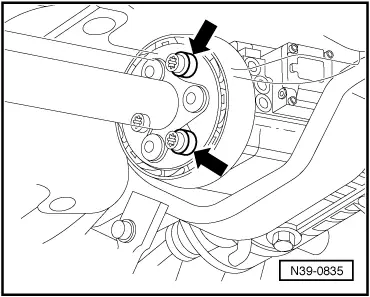

| Install the propshaft on the flange of the Haldex coupling in such a way that the markings -arrows- are on the same line. |

Note | t

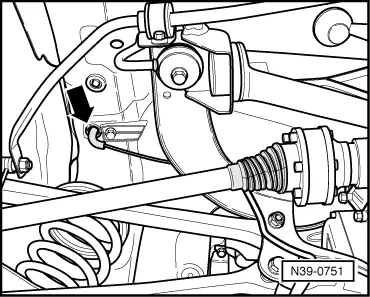

| If droning noises occur while driving, the following must be observed: |

| t

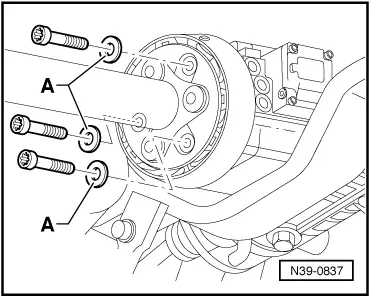

| Unscrew the propshaft with the flexible disk from the flange of the Haldex coupling and screw on again offset to a hole. |

| t

| If the droning noises can still be heard, the propshaft must be screwed on once again offset to a hole. |

| t

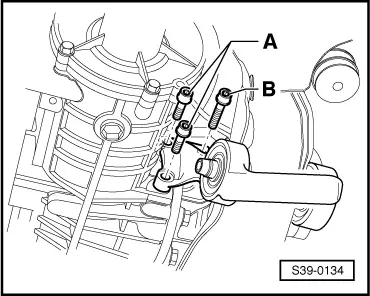

| Three protruding bushings at the Haldex coupling flange or the propshaft flange grip into the location holes of the flexible disks. |

|

|

|

Note

Note

Note

Note

Note

Note